HELM Damper Complete 100 Hour Service Instructions (Part 2 of 3)

June 2022 orig.

Table of Contents

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek forks have pressurized oil. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service. Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a fork still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

These service instructions cover the basic service procedures using standard service kits. If your suspension requires parts beyond standard replacement parts – CSU, compression rods, etc. – please consult your authorized Cane Creek service center or contact us at our Cane Creek Support Center.

Service Notes

These instructions cover just the damper leg of a complete 100 hour service. Combine these instructions with the appropriate spring side – air or coil; original or MKII – and 50 hour lower service to get a complete 100 hour fork service.

Additionally, follow these instructions for damper removal and reinstall if sending the damper off for a service with an authorized Cane Creek service center.

Service Kit

BAG0714 – HELM Damper Rebuilt Kit

Required Cane Creek Tools

BAG0405 – Compression Retaining Nut Socket – Thin Walled 11mm socket

AAG0086 – HELM Cartridge Fill Tool

AAG0367 – HELM Oil Seal Head Bullet

AAG0406 – HELM Compression Outer Sleeve Spanner

Additional Tools & Supplies

Allen wrenches – 4mm

Torx wrenches – T10

Sockets – 10mm & chamfer-less 30mm

Crowfoot wrenches – 10 & 18mm

Open Ended Box wrenches – 10 & 18mm

10mm Shaft Clamp

Torque wrenches

Knipex pliers

Pick

Suspension Grease

PolyLube Grease

Motorex 2.5wt Racing Fork Oil

Vacuum Oil Fill Machine

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

| Rebound Piston Assembly | 3 Nm | 263 (Red) |

| Rebound Piston Install | 5 Nm | 243 (Blue) |

| Rebound Adjuster | 5 Nm | 243 (Blue) |

| Damper Top Cap to Gold Coupling | 9 Nm | None |

| Oil Seal Head to Damper Tube | 13 Nm | None |

| Damper Install | 36 Nm | 243 (Blue) |

| Compression Nut | Hand Tight | 243 (Blue) |

| LSC Knob Screw | 1.6 Nm | 243 (Blue) |

Oil Chart

| Oil Location | Oil Type | Oil Amount |

|---|---|---|

| Damper Fill | Motorex 2.5wt Racing Fork Oil | Fill to 2 Bars |

Damper Reassembly

Step 1 – Rebound Piston Assembly (if necessary)

If necessary, install check spring or wave washer on piston seat with concave side up, bottom shim, piston with small ports facing up, shim stack, and spacer. Shim stack goes in order from largest to smallest. Apply red (263) Loctite to jam nut and install. Check that bottom shim is not pinched on piston seat and is centered. Using two 10mm sockets, torque to 3 Nm.

TSB015 – Rebound Piston Flip

TBS029 – Check Spring Change

Wave Washer (or Check Spring) on Piston Seat

Bottom Shim on Piston Seat

Wave Washer (or Check Spring) & Bottom Shim on Piston Seat

Rebound Piston Install

Rebound Piston Installed

Shim Stack Installed

Spacer Install

Spacer Installed

Applying Loctite to Jam Nut

Rebound Piston Assembly Ready for Torque

Rebound Piston Assembly w/ Check Spring

Rebound Piston Assembly on 10mm Socket

Rebound Piston Assembly Torque

Step 2 – Rebound Piston Install (if necessary)

Install new piston band (AAG0212) on rebound piston. Apply blue Loctite (243) to rebound piston assembly threads and install into damper shaft. Reinstall low speed needle spring if removed. Clamp damper shaft with 10mm shaft clamp with piston end up. Torque piston assembly to 5.0 Nm with 10mm crowfoot.

Piston Band Install

Applying Loctite to Piston Assembly

Low Spring Needle Spring Install

Piston Assembly Install

Piston Assembly Torque

Step 3 – Oil Seal Head Install

Grease bushing on new oil seal head (AAG0208). Using Oil Seal Head bullet (AAG0367), install oil seal head onto damper shaft. Note orientation with threaded side towards piston end of shaft.

Greasing Oil Seal Head

Oil Seal Head Bullet

Oil Seal Head Install

Oil Seal Head Installed

Step 4 – Rebound Adjuster Install

Insert rebound shuttle rod into damper shaft. Apply blue Loctite (243) to rebound adjuster threads. Install rebound adjuster into damper shaft. Clamp damper shaft with 10mm shaft clamp. Torque adjuster to 5.0 Nm with 10mm crowsfoot. Grease and install rebound adjuster o-ring (AAD1060).

Rebound Shuttle Rod Install

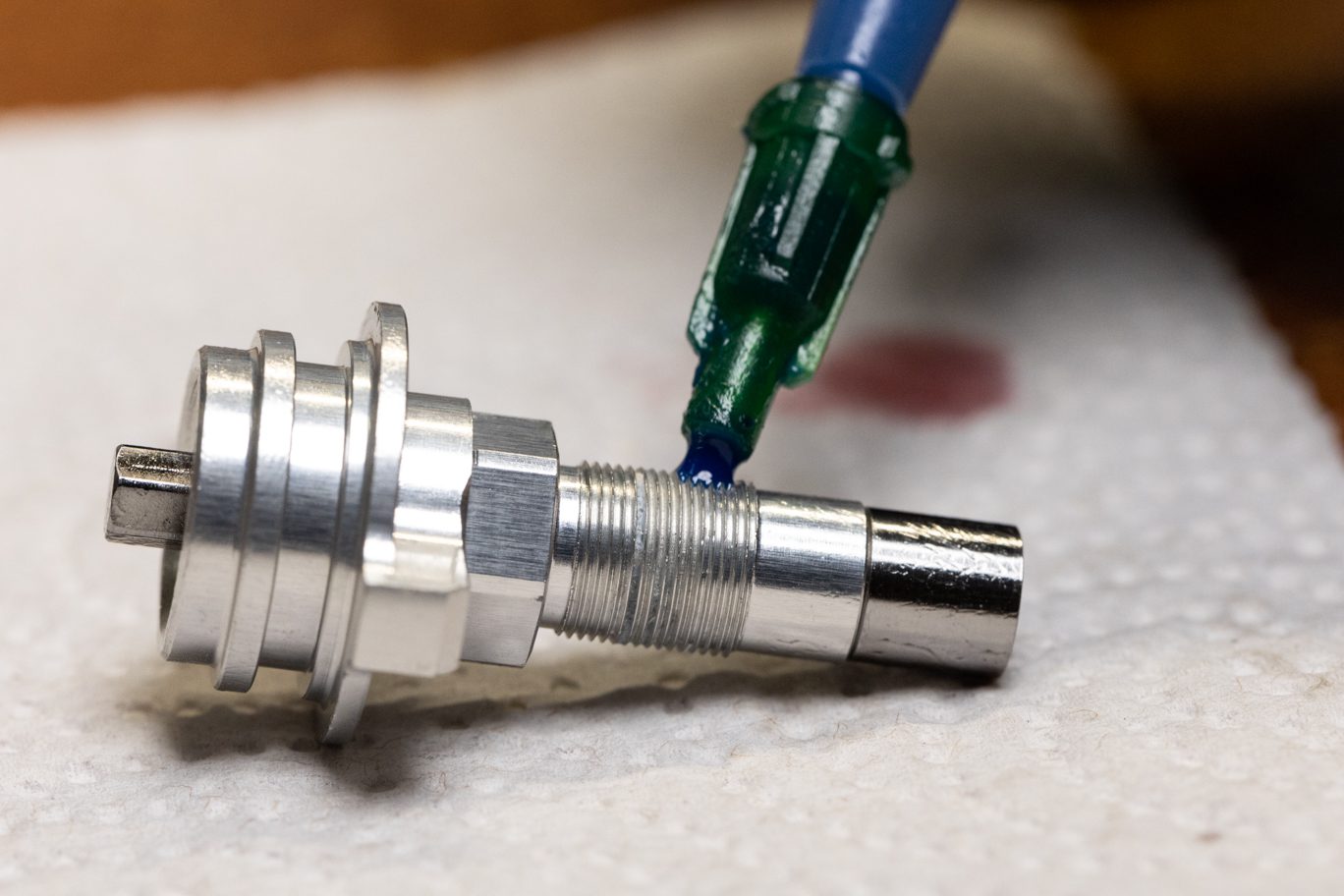

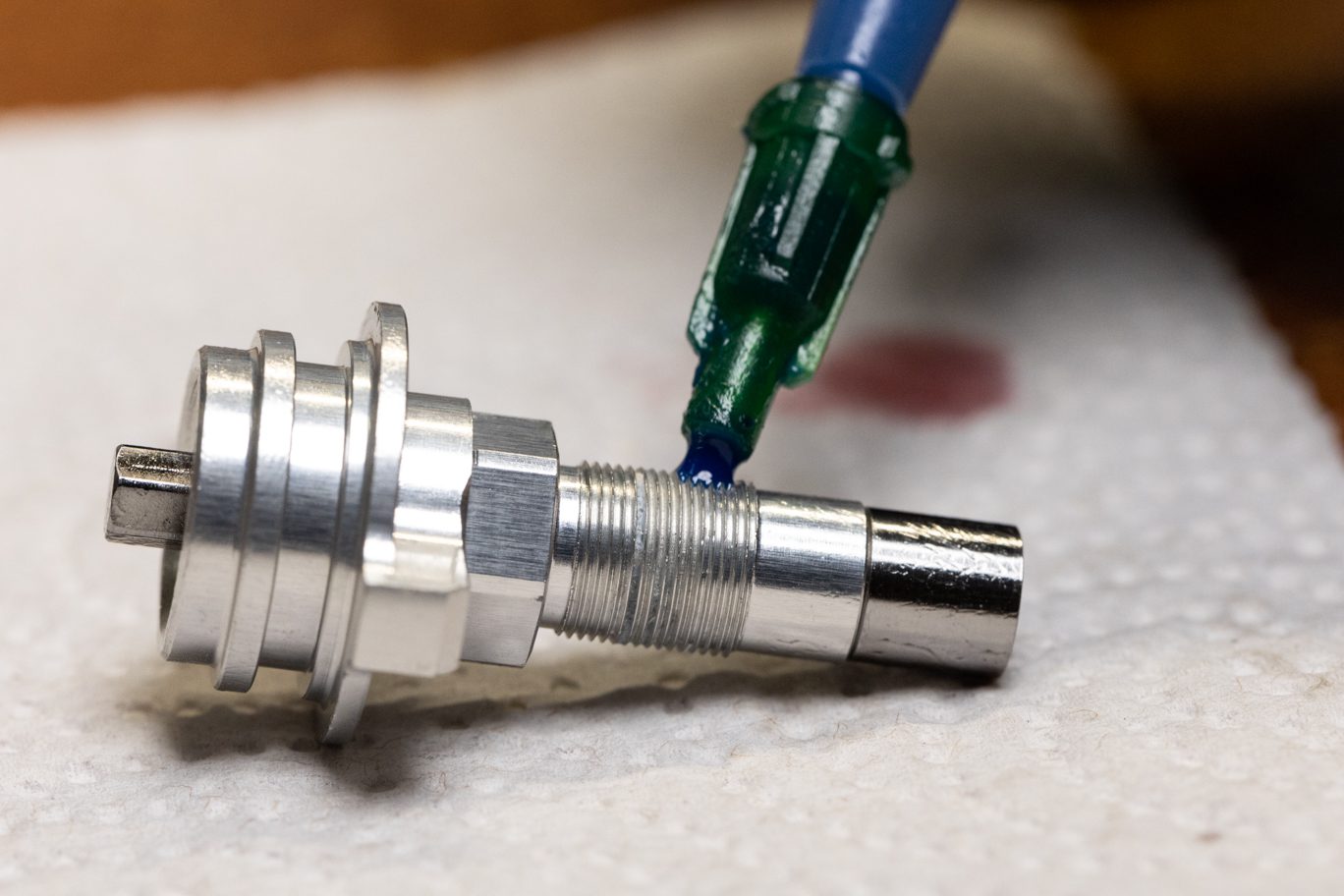

Applying Loctite to Rebound Adjuster

Rebound Adjuster Install 1

Rebound Adjuster Install 2

Rebound Adjuster Installed

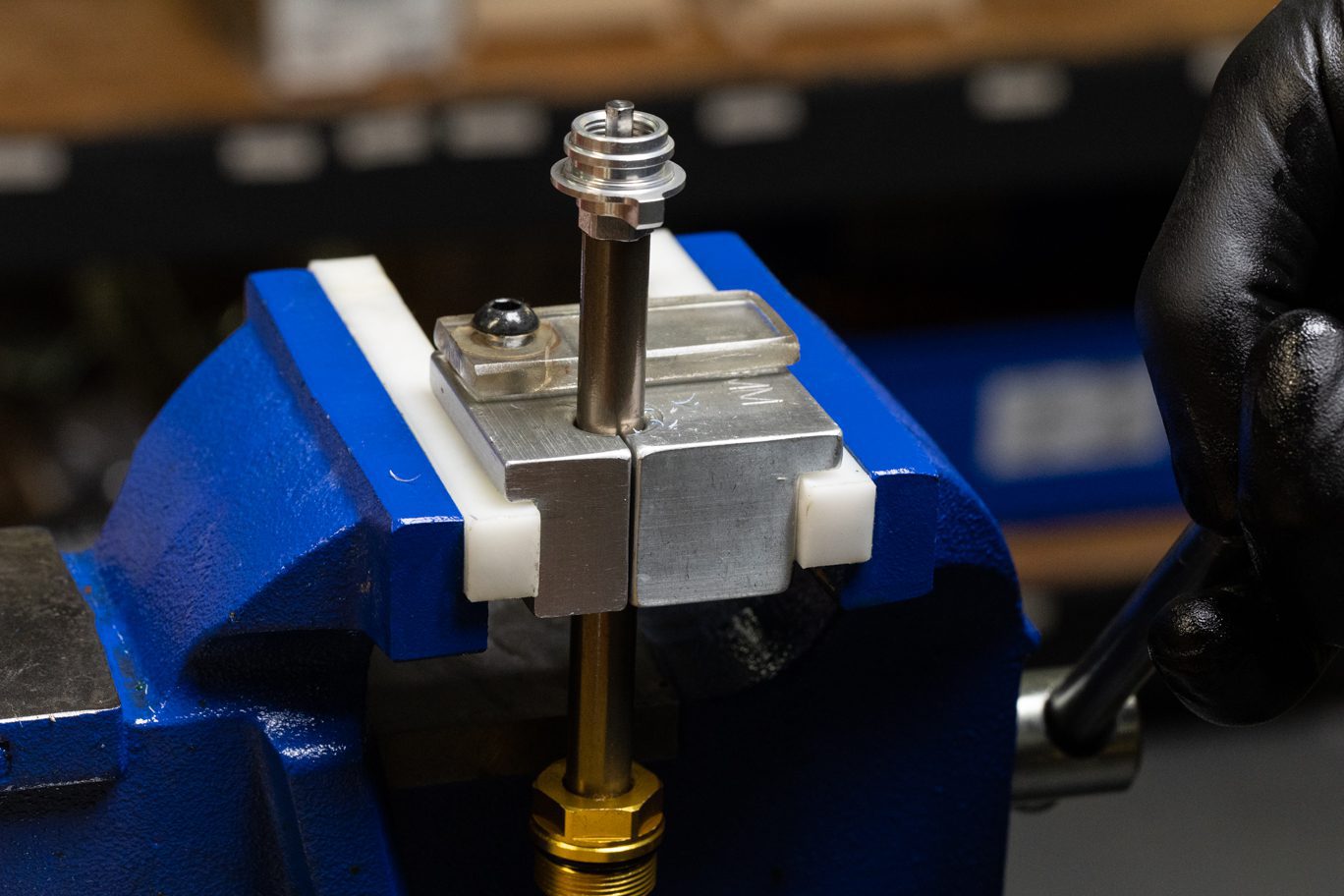

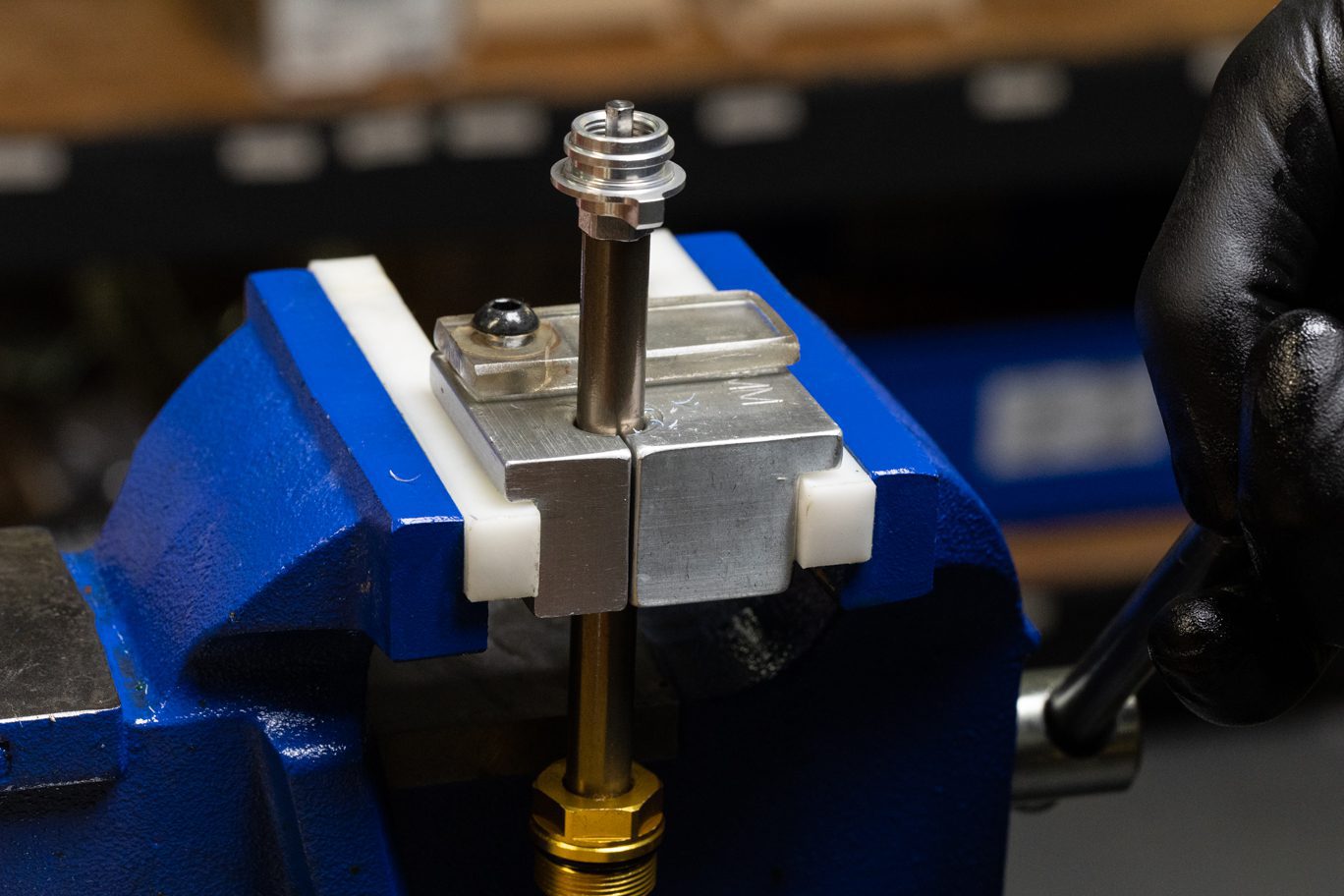

Shaft Clamped for Rebound Adjuster Torque

Rebound Adjuster Torque

Rebound Adjuster O-Ring Install

Rebound Adjuster O-Ring Installed

Step 5 – Piston Band Install (if Step 2 skipped)

Install new piston band (AAG0212) on rebound piston.

Piston Band Install

Piston Band Installed

Step 6 – Bladder, Claw & Helix Install

Install new bladder (AAG0216HNBR) on compression outer sleeve. Ensure bladder and outer compression sleeve threads are exposed. Insert claw into compression outer sleeve. Holding claw in place, place helix onto claw.

Bladder Install

Bladder Installed

Ensuring Thread Exposure

Claw Install

Claw Install

Holding Claw for Helix Install

Holding Claw for Helix Install

Step 7 – Detent Install

Apply suspension grease through the helix into the detent channel on the claw. Set the detent balls into the channel. Line up detent balls with channels on the outer sleeve and slide the helix & claw assembly into outer sleeve. Ensure claw moves up and down when rotating helix.

Detent Channels on Outer Sleeve

Applying Grease Through Helix

Detent Ball Install

Detent Ball Installed

Detent Balls Misaligned

Detent Balls Correctly Aligned

Step 8 – Damper Top Cap Install

Apply damper oil to inside of damper top cap. Holding claw in place, fully thread damper top cap onto compression outer sleeve. Using 10mm socket, check for free rotation of helix and claw. Leave fully open (counterclockwise).

Lubing Damper Top Cap

Holding Claw for Top Cap Install

Top Cap Install

Threading Damper Top Cap

Damper Top Cap Installed

Testing Helix & Claw 1

Testing Helix & Claw 2

Step 9 – Check Spring & Piston Assembly Install

Install compression check spring onto claw. Install compression piston assembly with poppet contacting spring.

Compression Check Ring Install

Compression Check Ring Installed

Compression Piston Assembly Install

Compression Piston Assembly Installed

Step 10 – Compression Circuit Reassembly

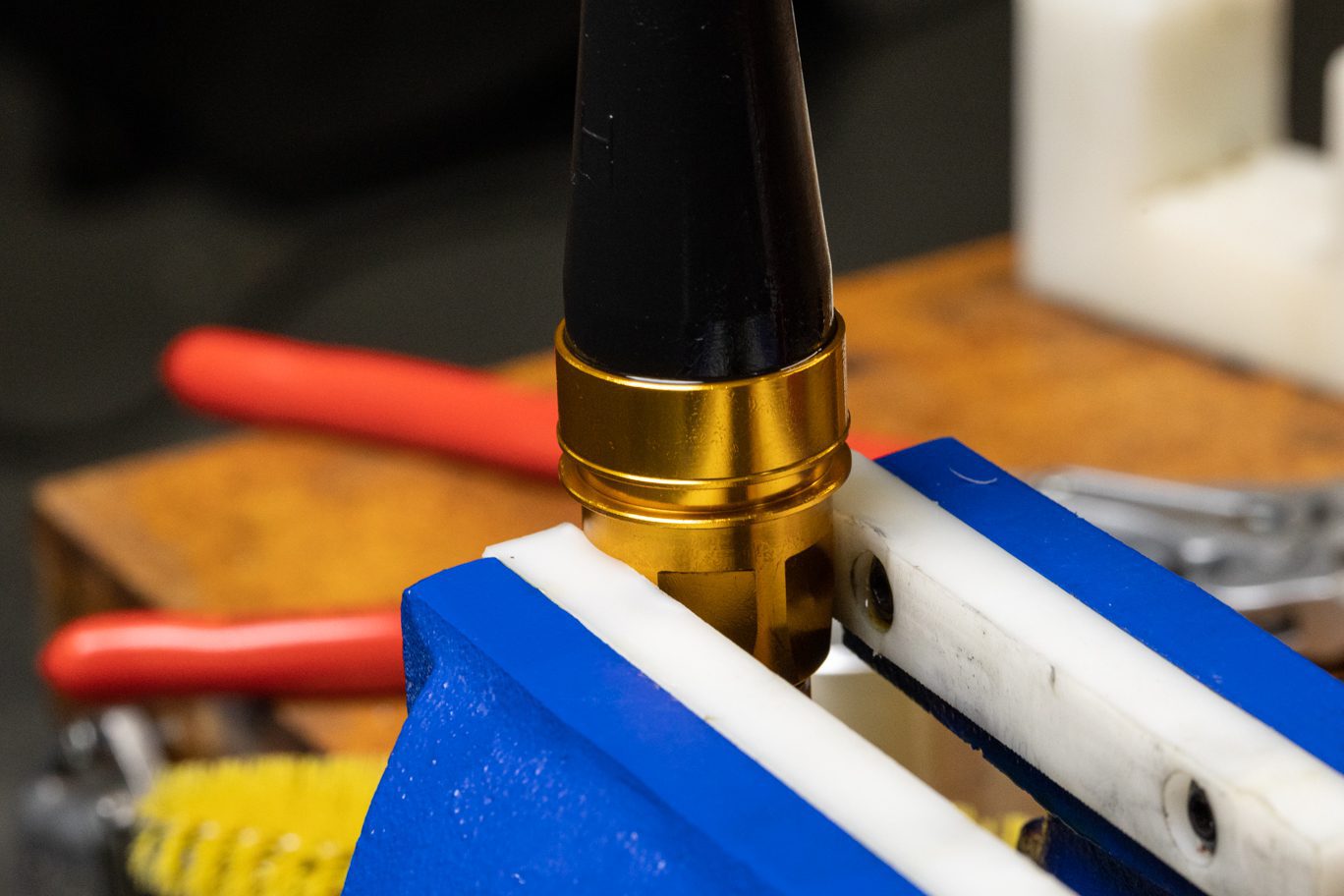

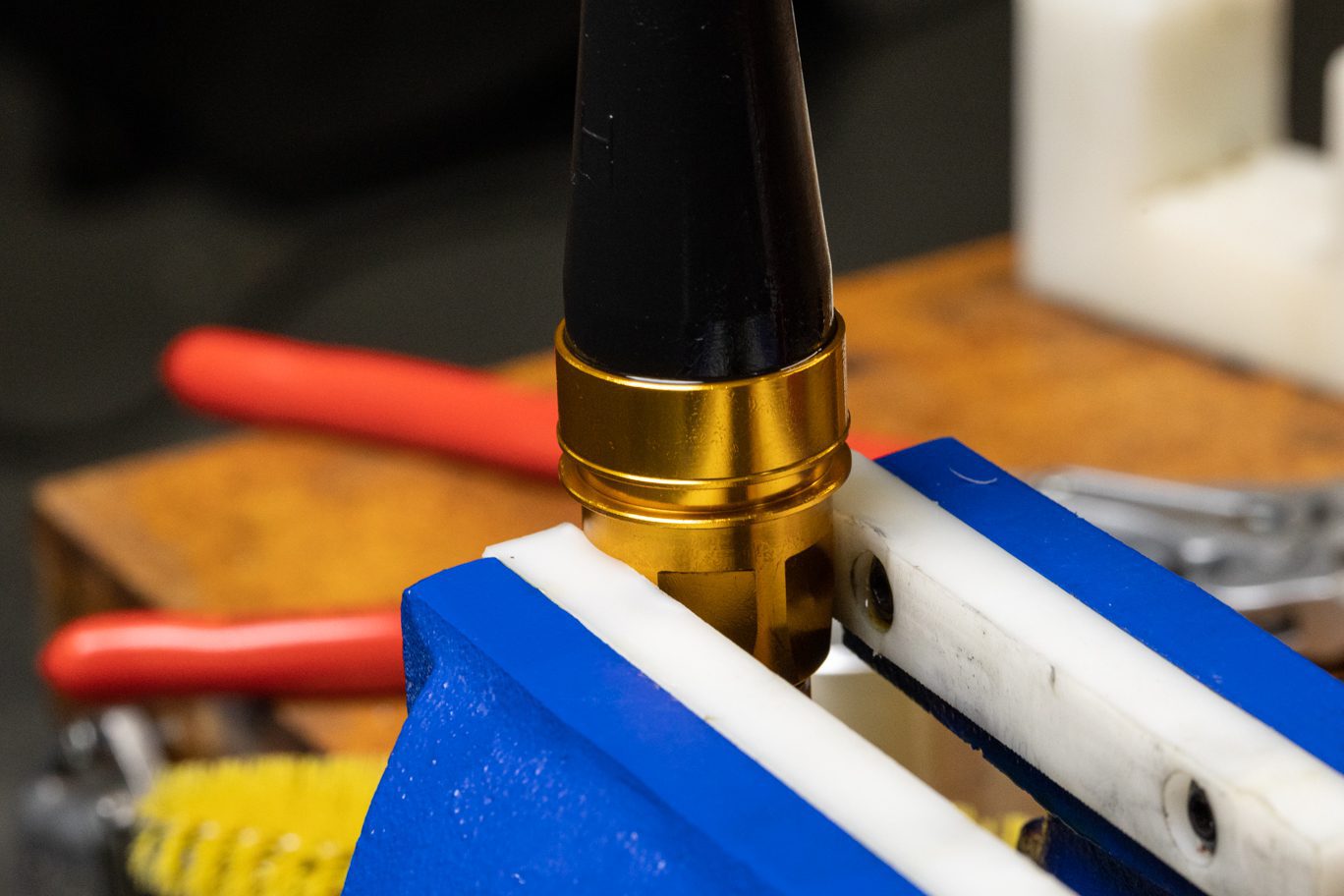

Apply damper oil to damper coupling. Thread damper coupling onto compression outer sleeve. Clamp damper coupling and torque damper top cap to 9 Nm using 30mm socket. Recheck that the helix still turns freely.

Applying Oil to Damper Coupling

Damper Coupling onto Outer Sleeve Install

Damper Coupling onto Outer Sleeve Installed

Tightening Damper Coupling onto Outer Sleeve

Damper Coupling Clamped

Tool to Top Cap

Damper Coupling Torque

Checking Helix Movement

Step 11 – Rebound Circuit Install

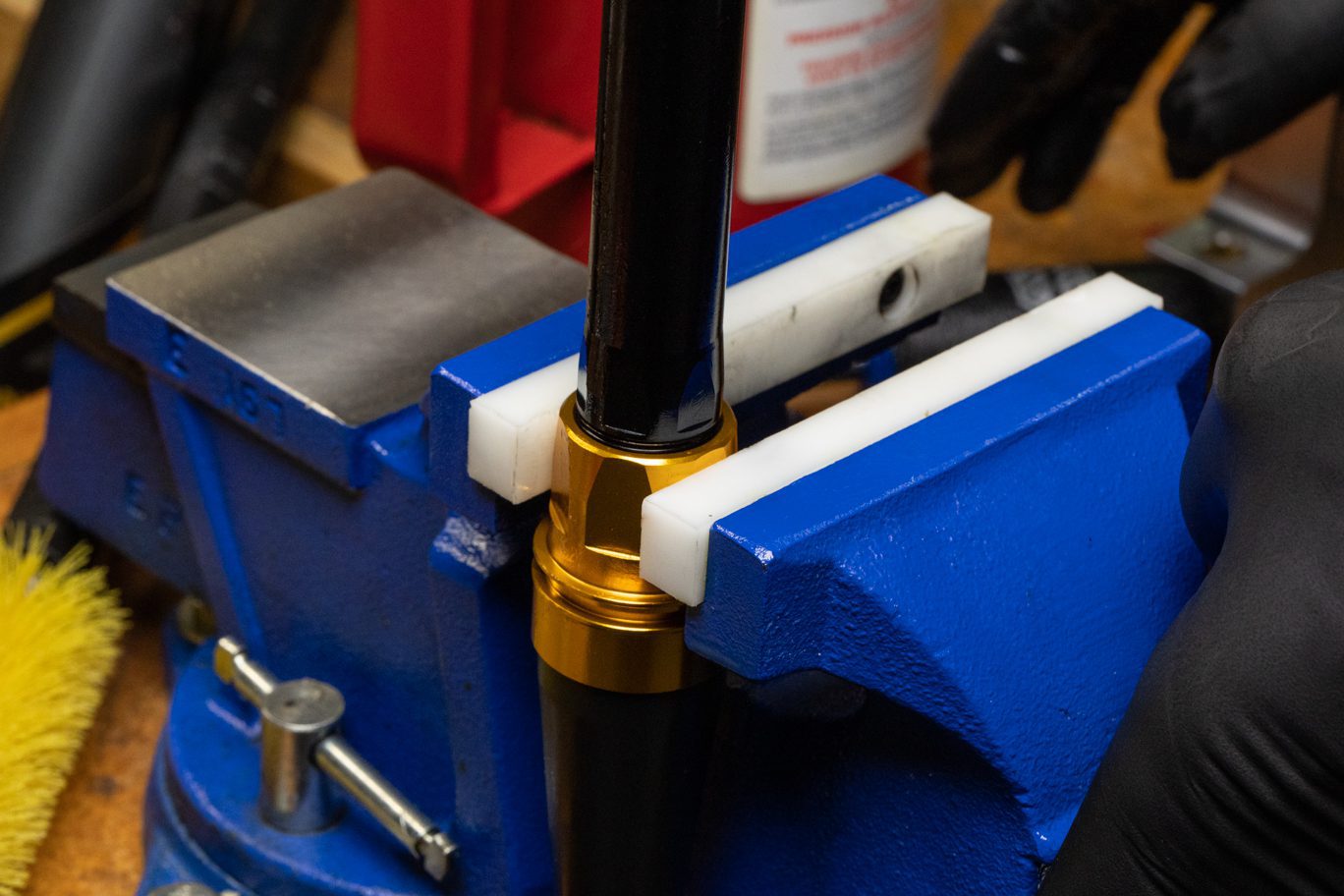

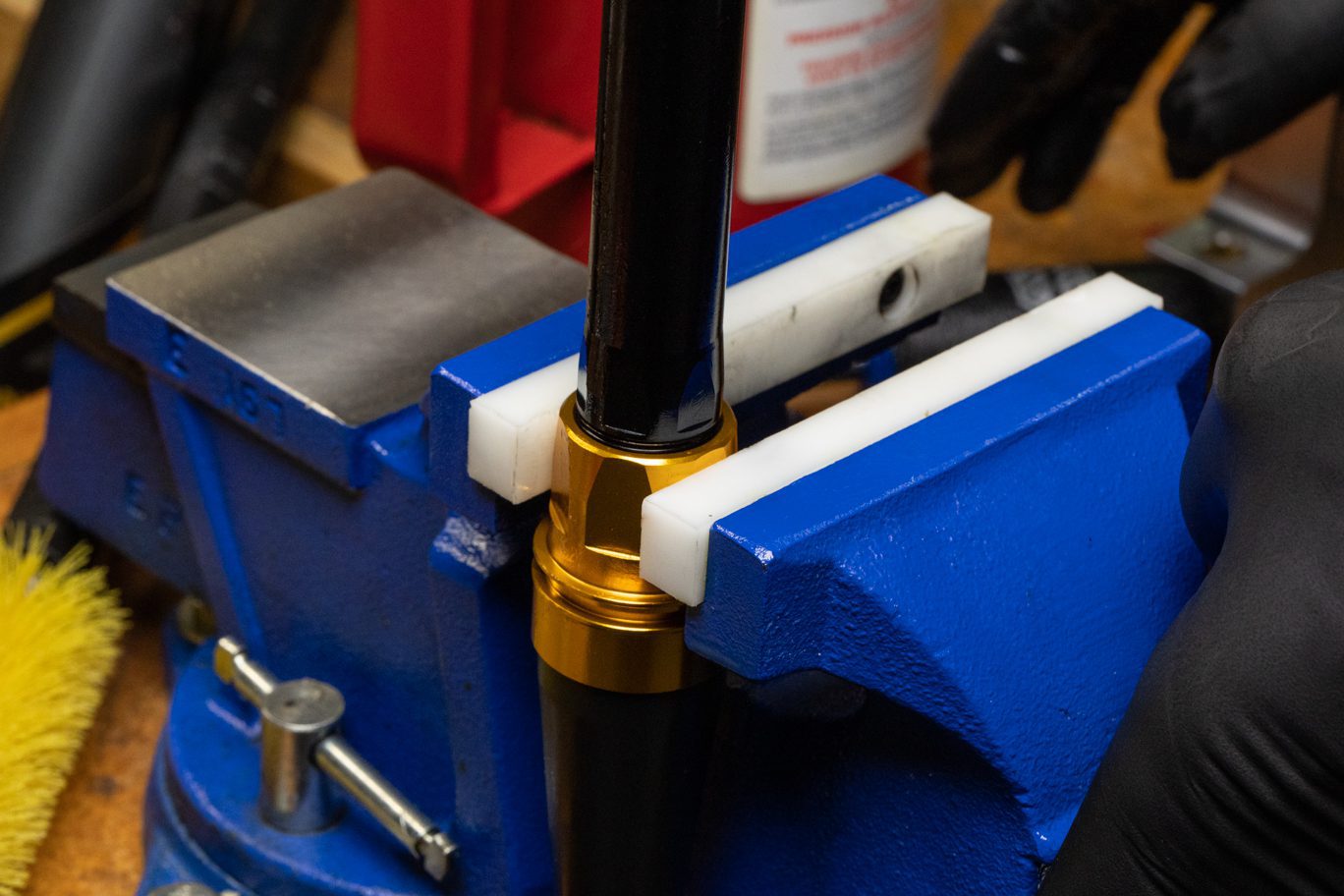

Coat rebound piston in damper oil. Insert rebound assembly into damper tube. Thread oil seal head into damper tube. Secure damper coupling using vise or Knipex and torque oil seal head to 13 Nm using 22mm crowfoot.

Coating Rebound Piston

Rebound Circuit Install

Rebound Circuit Installed

Clamping Damper Coupler (Knipex)

Clamping Damper Coupler (Vise)

Oil Seal Head Torque (Knipex)

Oil Seal Head Torque (Vise)

Continue to Part 3

Next