DBKitsuma Coil Complete 100 Hour Service Instructions (Part 3 of 4)

Mar 2022 orig., Jul 2023 rev.

Table of Contents

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek shocks have pressurized nitrogen and oil, even coil shocks. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service.

Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a shock still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

These service instructions cover the basic service procedures using standard service kits. If your suspension requires parts beyond standard replacement parts – shaft, damper tubes, end eyes – please consult your authorized Cane Creek service center or contact us at our Cane Creek Support Center.

Service Notes

The Kitsuma Air and Coil share many service steps. Additionally, the Standard and Trunnion variants of both models have identical service procedures other than where to clamp the cylinder head. Some images in these instructions may not be identical to the valve body or outer damper tube on the Kitsuma Air, but process is the same for the shock in the image and the shock on your bench.

BCD0338-01 – Kitsuma Coil Complete Rebuild Kit (w/ Bladder)

BCD0169 – Bladder Res End Cap (if replacing older IFP system)

Required Cane Creek Tools

ACD0354 – Bladder Res End Fill Tool

DBT018 – DB Seal Head Pin Spanner Wrench

AAD1361-01 – DBCoil/ DBAir – Oil Fill Needle Adapter

DBT016 – DB Gas Fill Needle

AAD0555 – 8mm & 9.5mm Shaft Clamp

AAD2465 – Kitsuma Valve Seat Tool

ACD0322 – Kitsuma Low Speed Detent Funnel

BAD1298 – DB 9.5mm Shaft Bullet

DBT012 – DB IFP Setting Tool

Additional Tools & Supplies

Torx wrenches – T10 & T20

Sockets – 4, 8 & 13mm

9.5mm Shaft Bullet

Torque wrenchesKnipex pliers

Pick

Strap wrench

Suspension Grease

PolyLube Grease

Motorex 4wt Racing Fork Oil

Vacuum Oil Fill Machine

Nitrogen Fill System

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

| Shaft Nut | 14.5 Nm | 243 (Blue) |

| Outer Damper Tube | Tight | 263 (Red) |

| Valve Seat | 4.8 Nm | None |

| High Speed Adjuster | 7 Nm | None |

| Climb Switch Screw | 1.2 Nm | 243 (Blue) |

| Oil Seal Head | 22 Nm | None |

| End Eye | 4.8 Nm | 243 (Blue) |

Oil Chart

| Oil Location | Oil Type | Oil Amount |

|---|---|---|

| Damper Fill | Motorex 4wt Racing Fork Oil | Fill to 3 Bars |

Nitrogen Chart

| Nitrogen Location | Nitrogen Pressure |

|---|---|

| Valve Body | 11 - 12 Bars |

Related Technical Service Bulletins

Review all related TSBs before performing any service.

TSB038 – Kitsuma HSR Revalve

TSB039 – Kitsuma High Speed Cap (ACD0275) Loctite Removal from Installation

TSB040 – Kitsuma Coil Endeye Material Change

TSB043 – Kitsuma Coil Shaft Lengthened & Washer Added

TSB045 – Kitsuma IFP Changed to Bladder

TSB048 – Kitsuma Oil Seal Head Torque Valve

Damper Reassembly

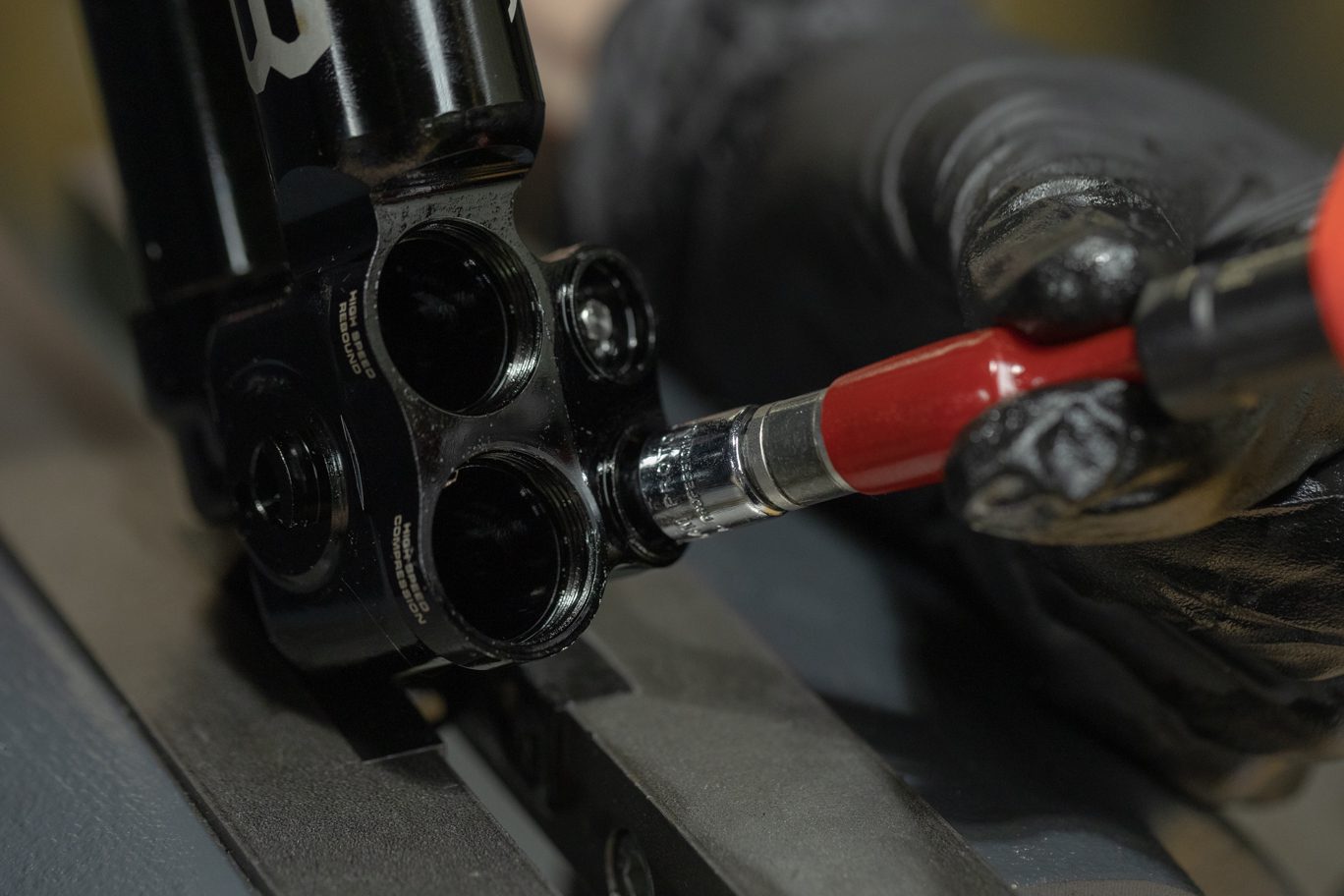

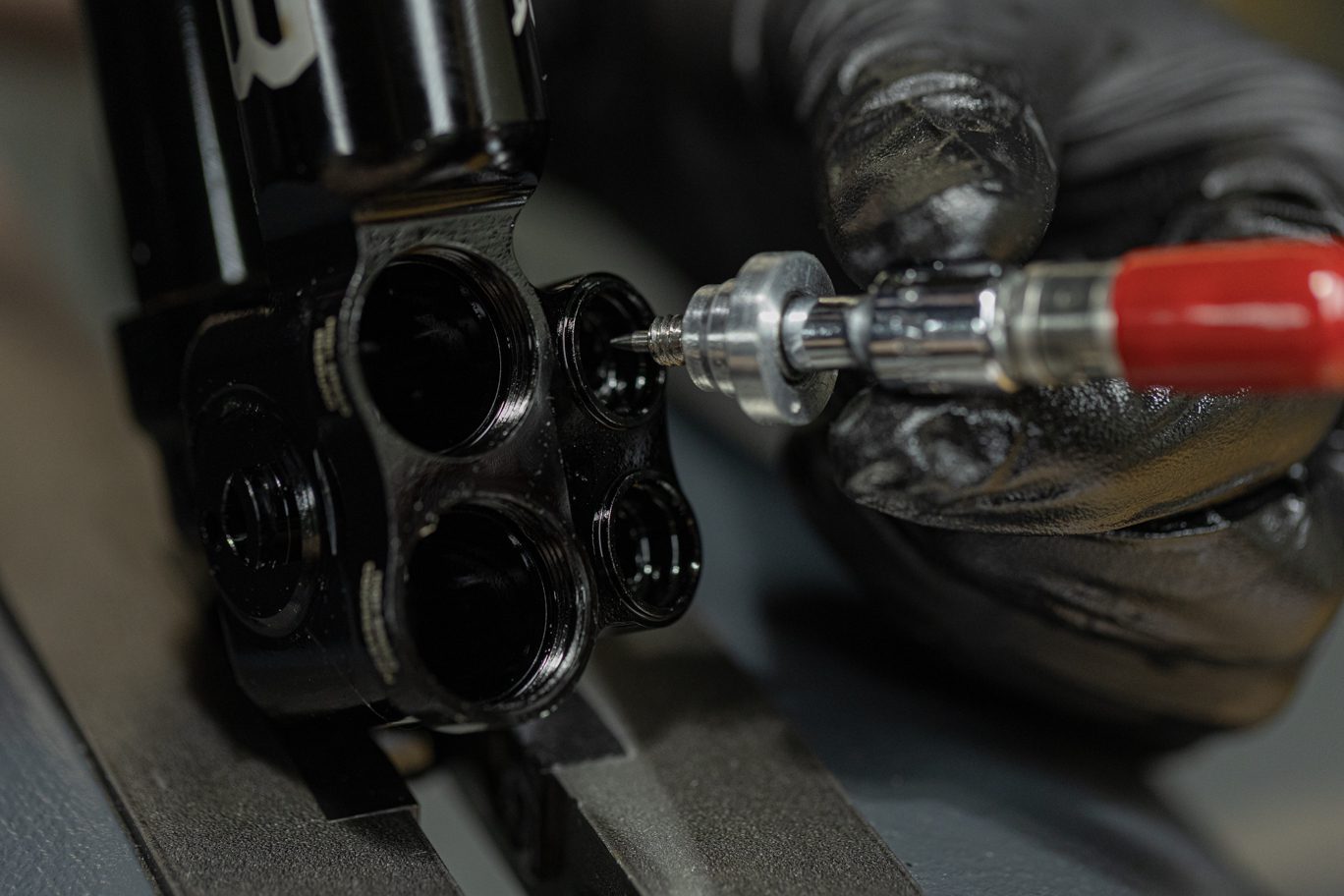

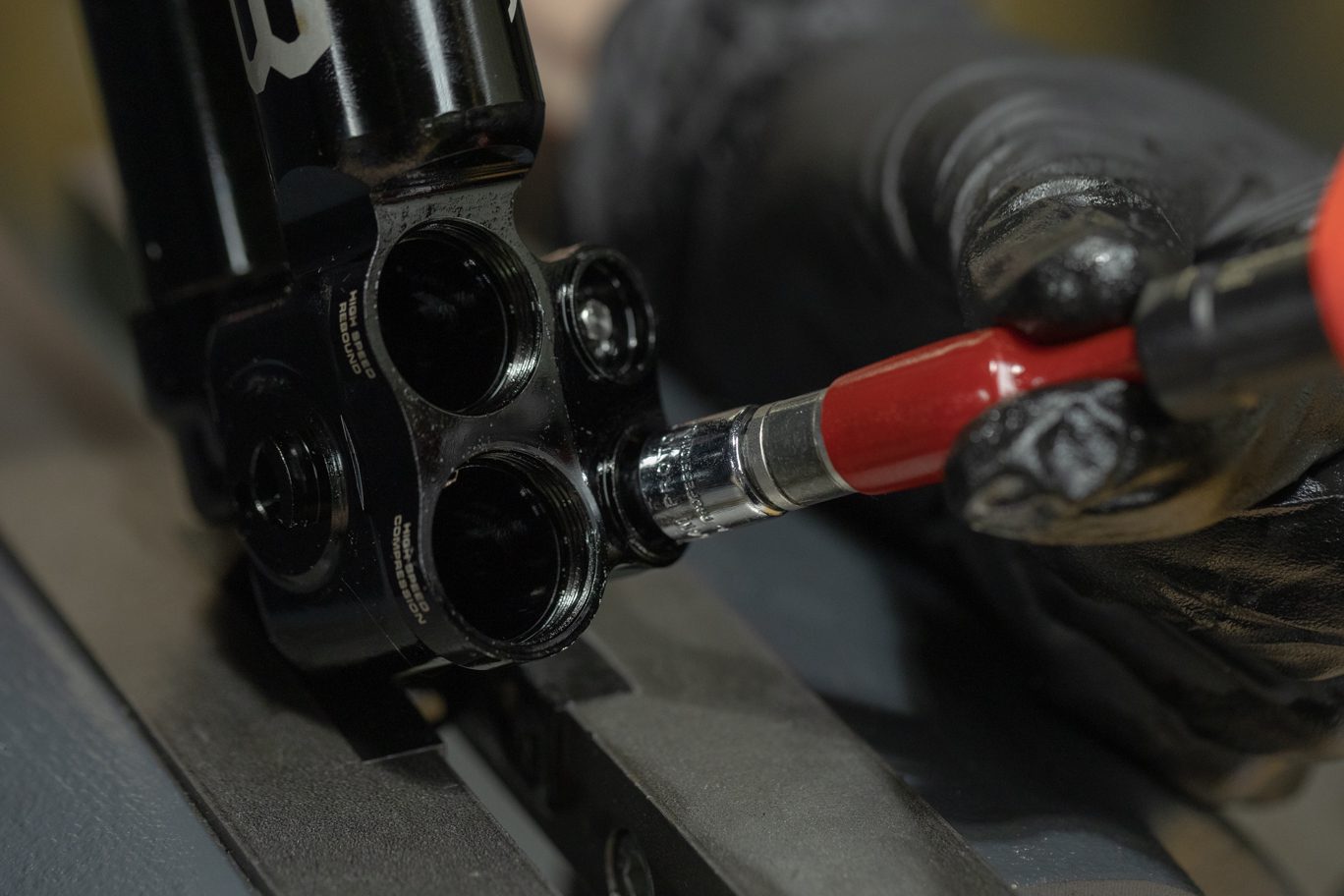

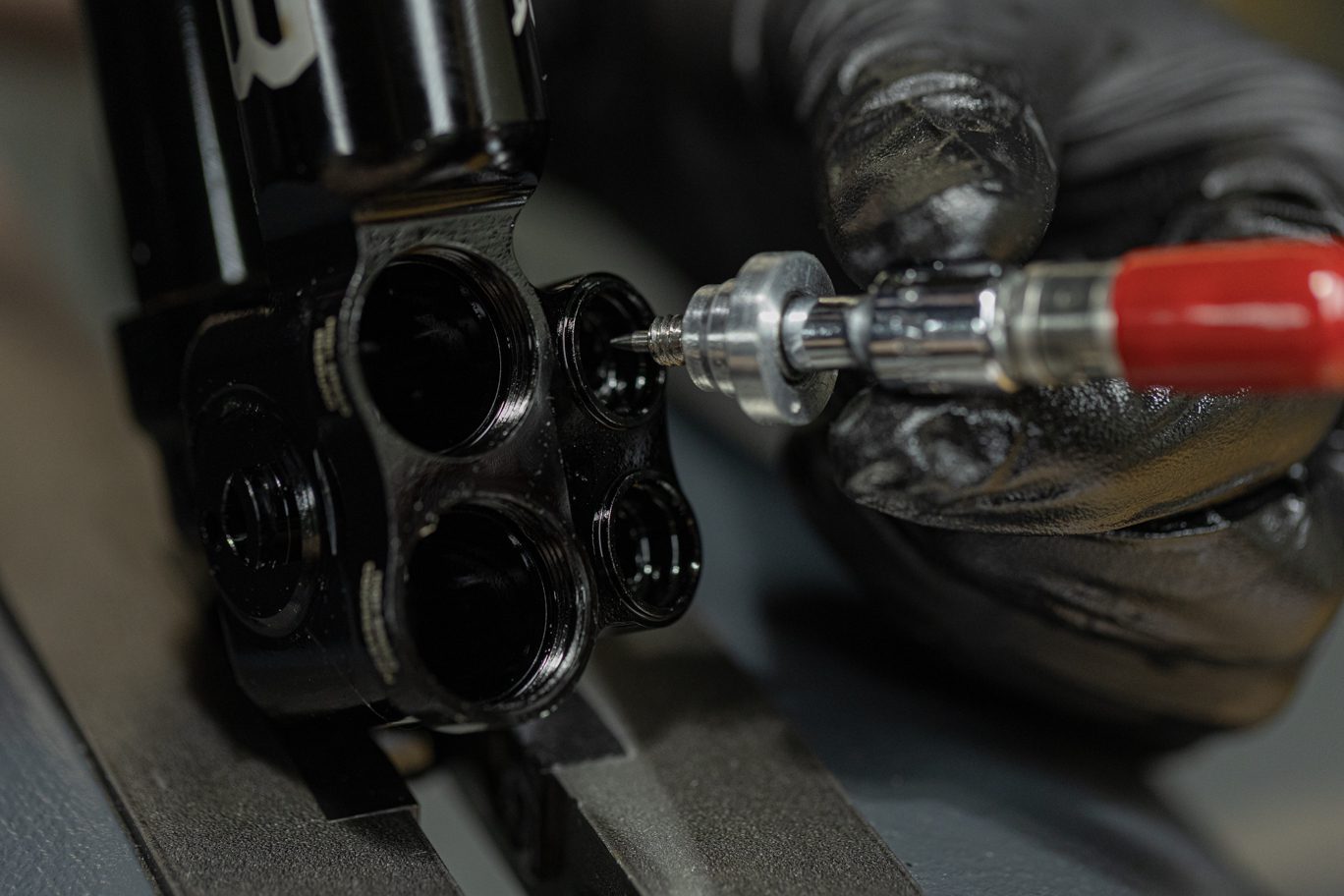

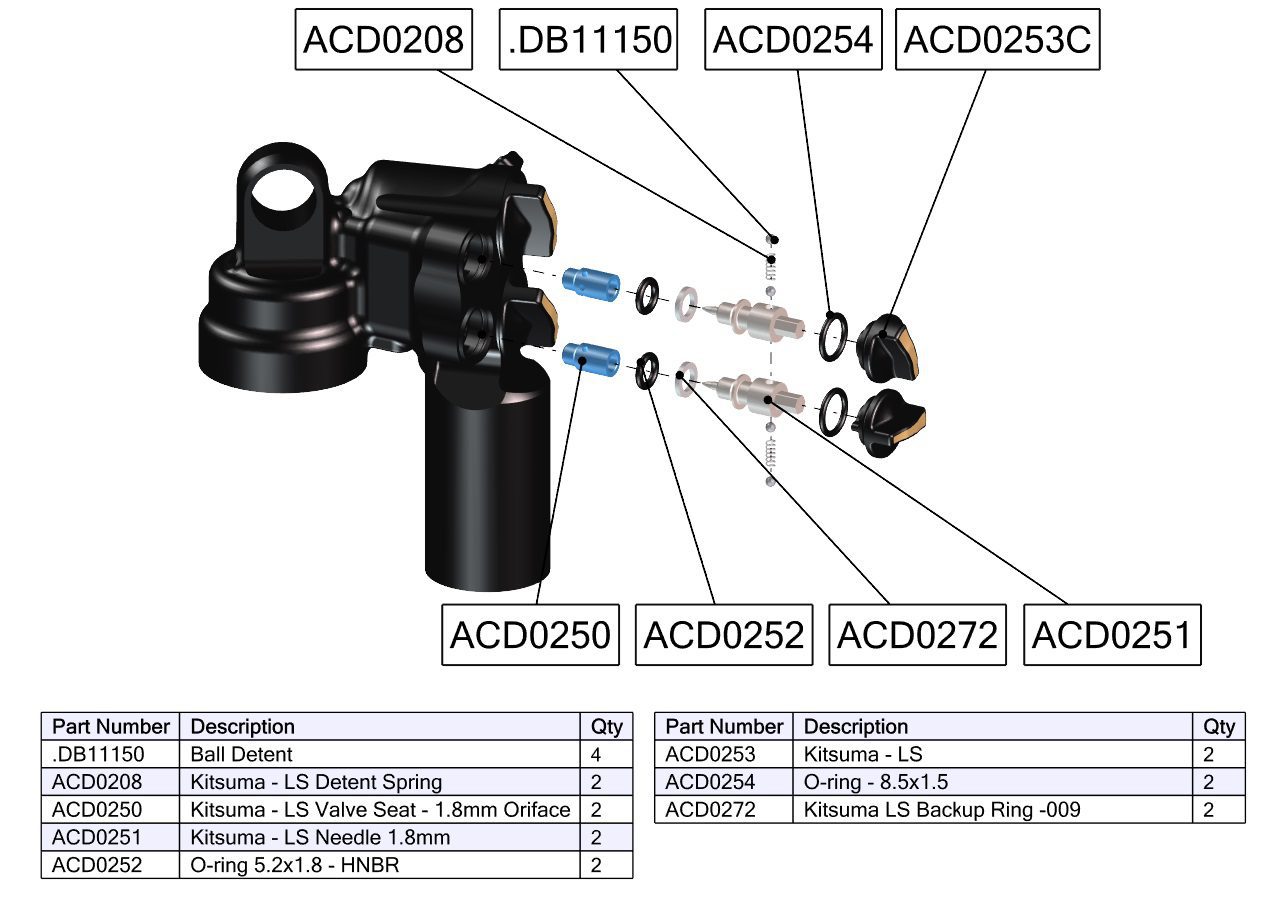

Step 1 – Low Speed Needles Install

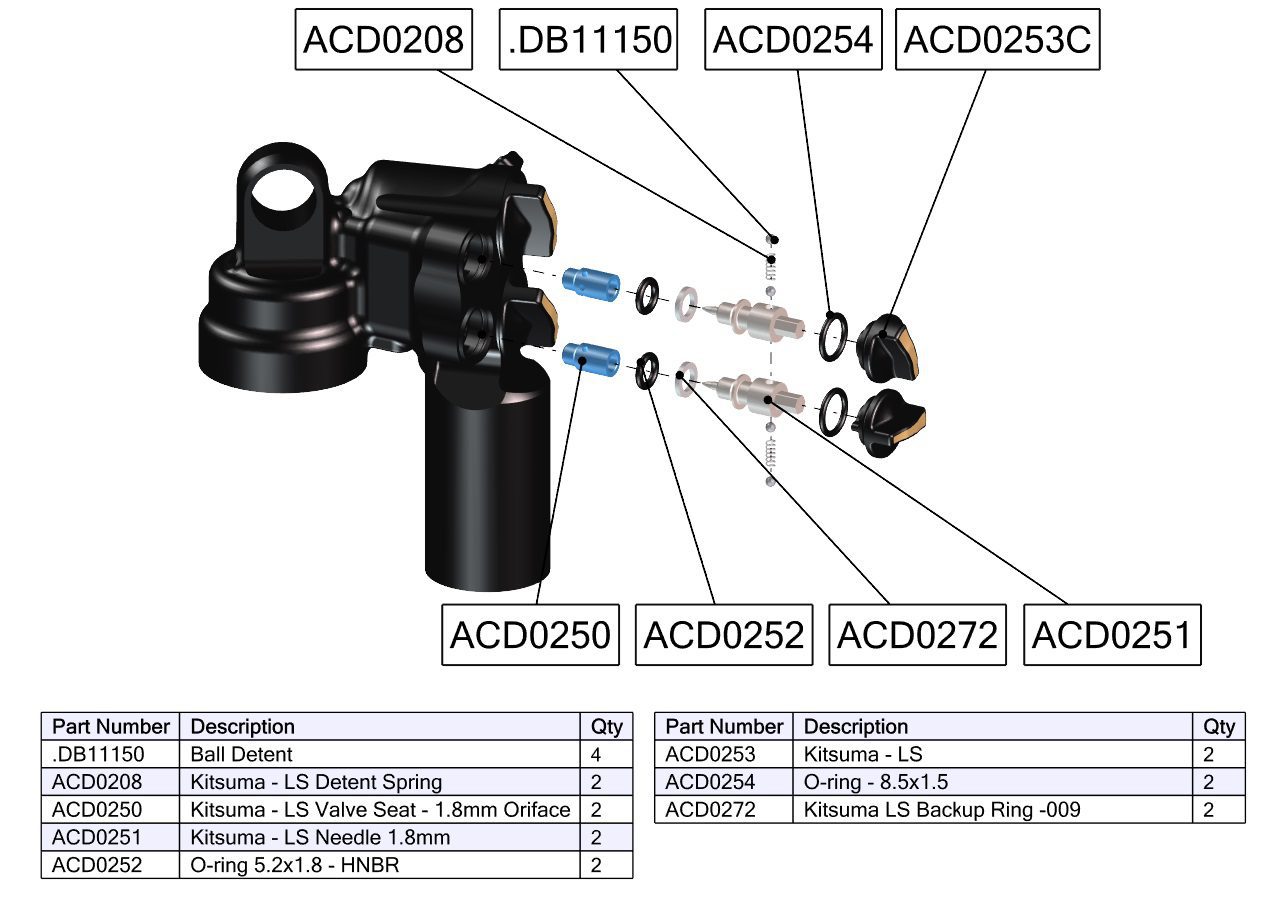

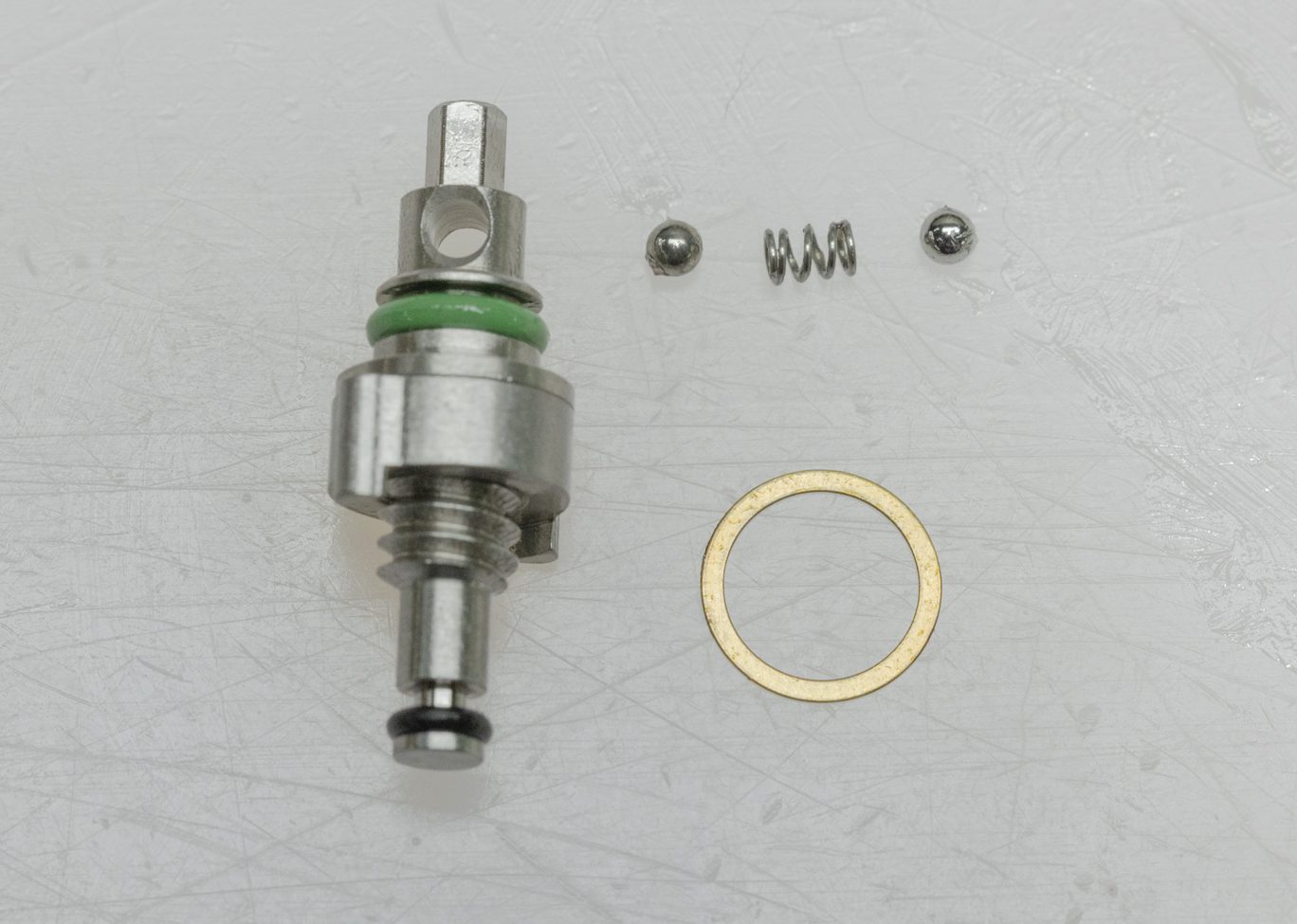

Install new back up ring (ACD0272) and lightly greased o-ring (ACD0252) on low speed needles. Using grease, reinstall spring and detent balls into low speed needles. Install low speed needles into valve body. Needle detent funnel (ACD0322) maybe used to ease install. Thread until bottomed then back out to ensure detents engagement. Then lightly bottom out the needle again.

Low Speed Needle Back Up Ring Install

Low Speed Needle O-Ring Install

Low Speed Needle O-Ring & Back Up Ring Installed

Low Speed Needle Detent Balls & Spring

Complete Low Speed Needle

Low Speed Needle Install 1

Low Speed Needle Install 2

Low Speed Needle w/ Funnel Tool

Low Speed Needle Install w/ Funnel Tool

Low Speed Needle Installed

Exploded Low Speed Needle Assembly

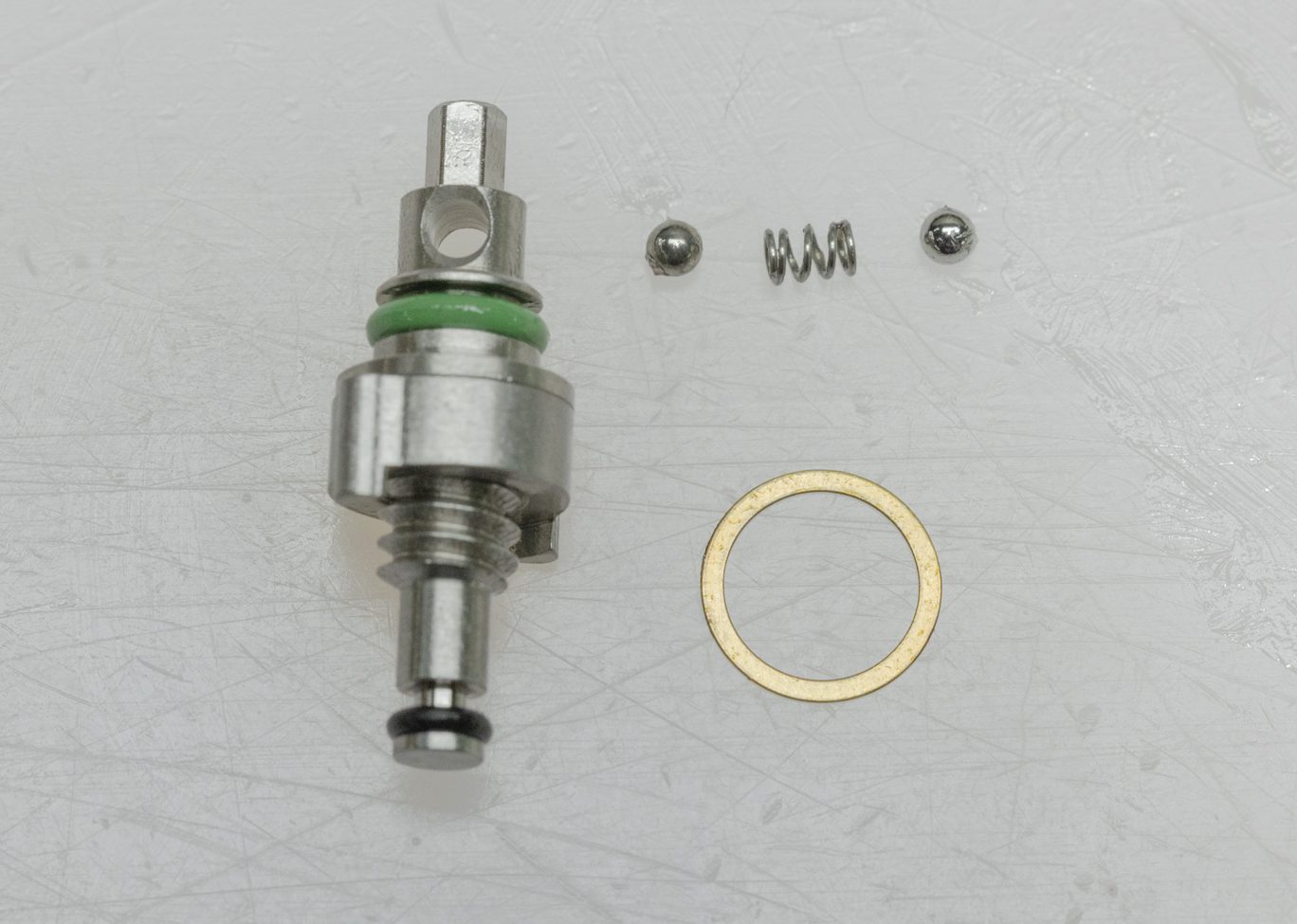

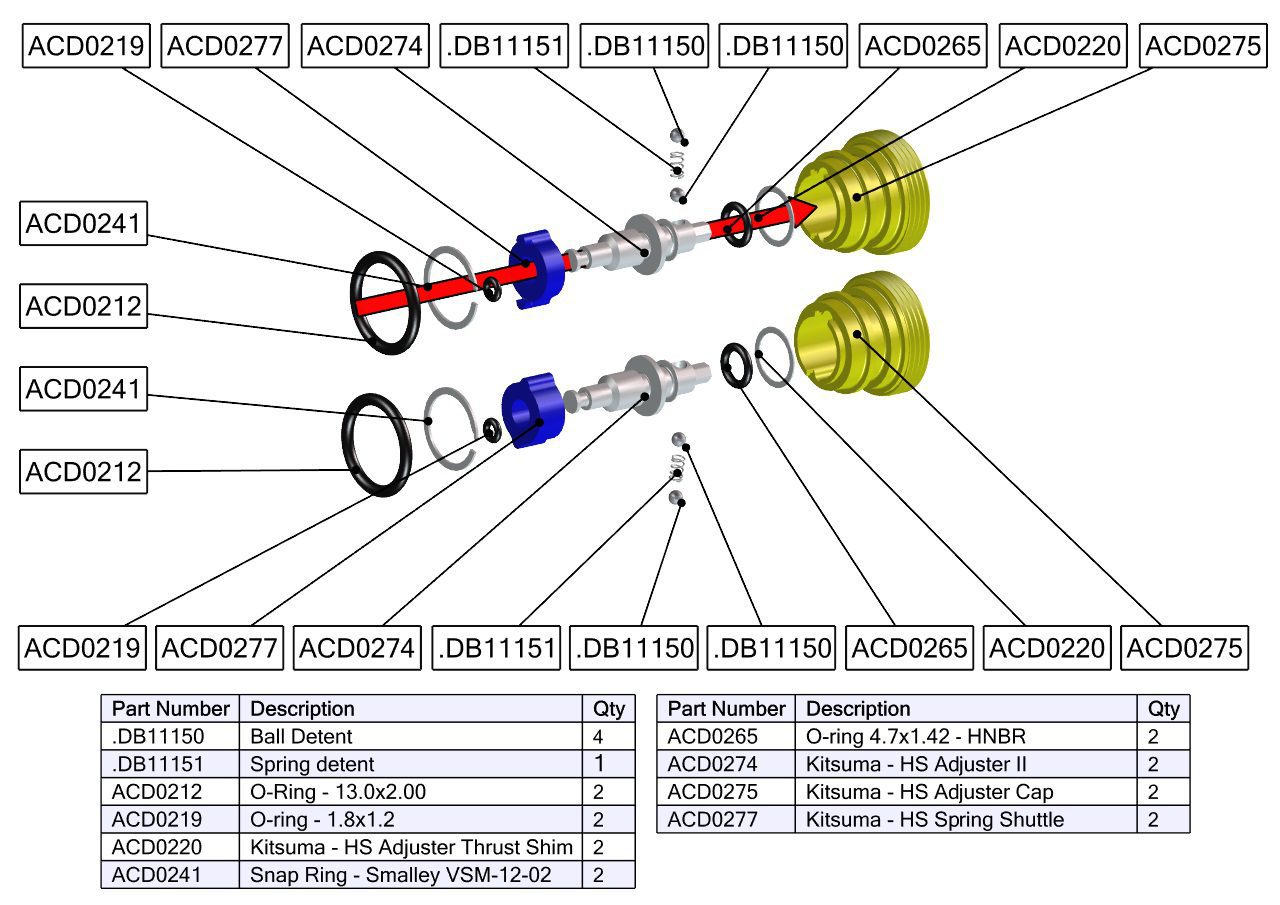

Step 2 – High Adjuster Shuttle Assembly

Thoroughly clean high speed adjustor threads and shuttle. Install shuttle onto adjustor. Note the orientation of the shuttle. Lightly grease and install high speed adjustor o-ring (ACD0265) and poppet o-ring (ACD0219).

TSB038 – Kitsuma HSR Revalve

Threading Shuttle onto High Speed Adjuster

Shuttle on High Speed Adjuster

Adjuster O-Ring Install

Adjuster O-Ring Installed

Poppet O-Ring Install

Assembled High Speed Adjuster

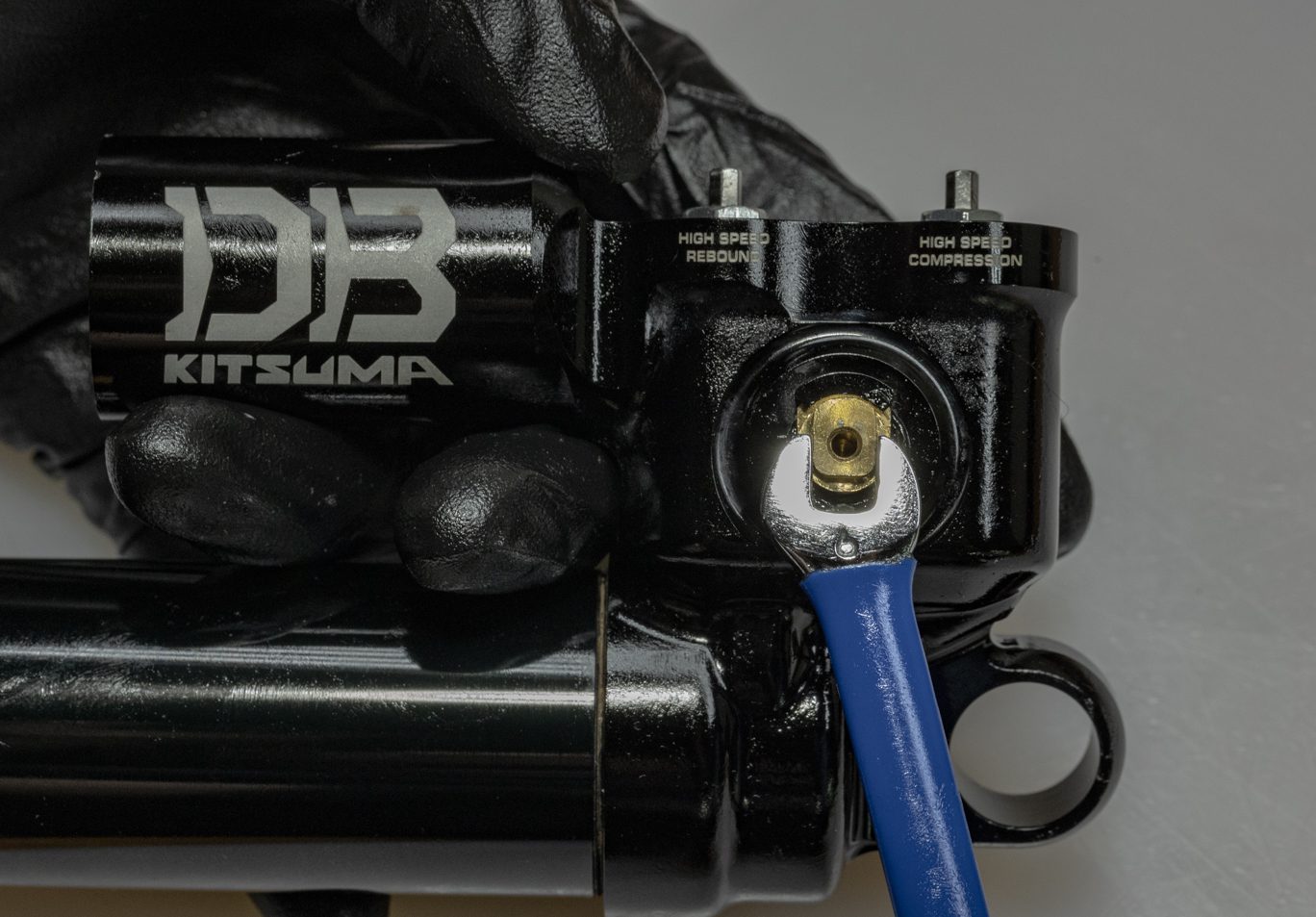

Step 3 – High Speed Adjuster Housing Assembly

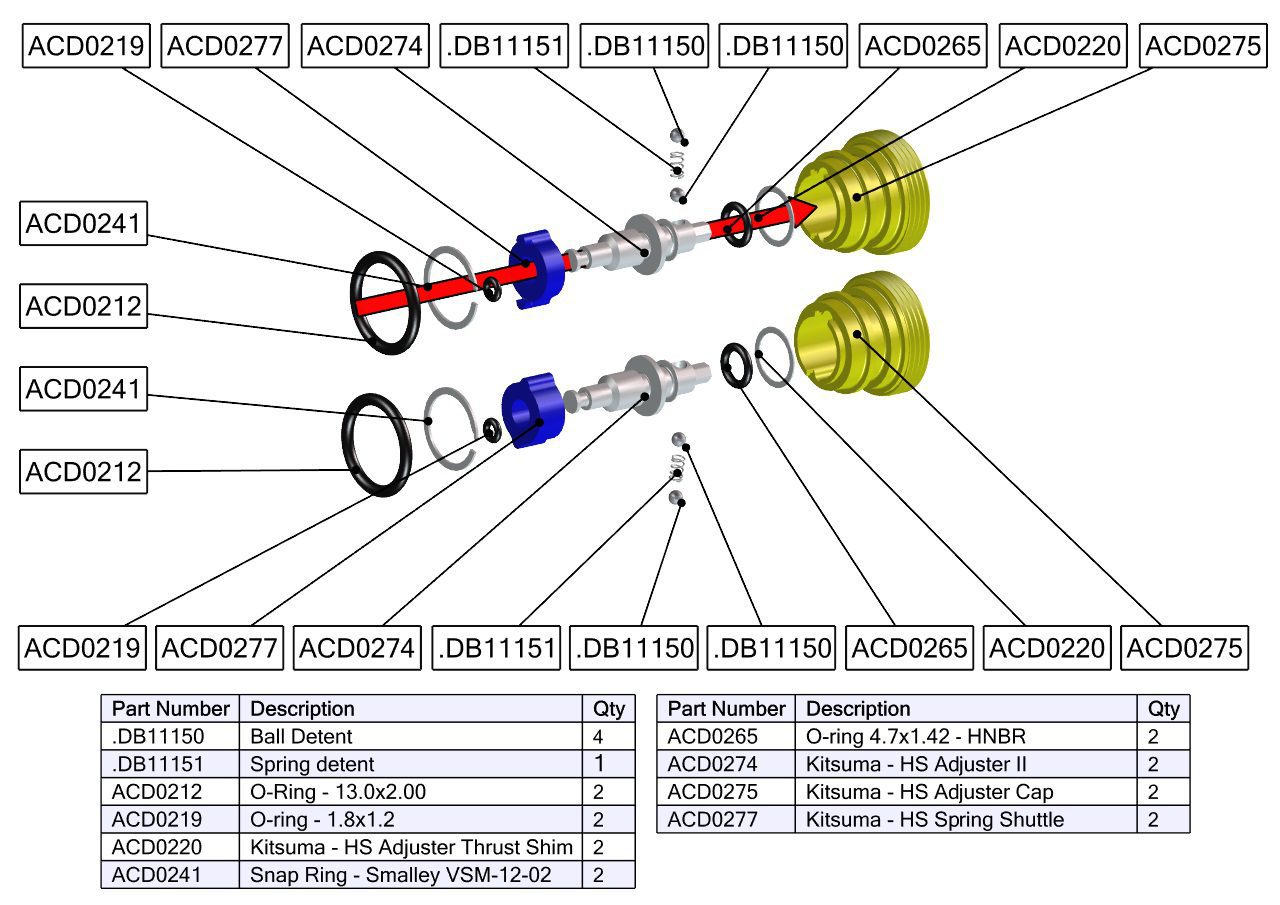

Insert gold shim into bottom of high speed adjustor housing. Using grease, reinstall spring and detent balls into high speed adjuster. Insert assembled high speed adjustors into high speed adjutor housing. Install circlip. Lightly grease and install high speed adjustor housing o-ring (ACD0212).

High Speed Adjustor Before Housing Install

Housing Gold Shim Install

Housing Gold Shim Installed

High Speed Adjuster Detent Balls & Spring Installed

High Speed Adjuster Inserting into Housing

High Speed Adjuster Inserted into Housing

High Speed Adjuster Housing Circlip Install

High Speed Adjuster Housing Circlip Installed

High Speed Adjuster Housing O-Ring Install

High Speed Adjuster Housing O-Ring Installed

Exploded High Speed Adjuster Assembly

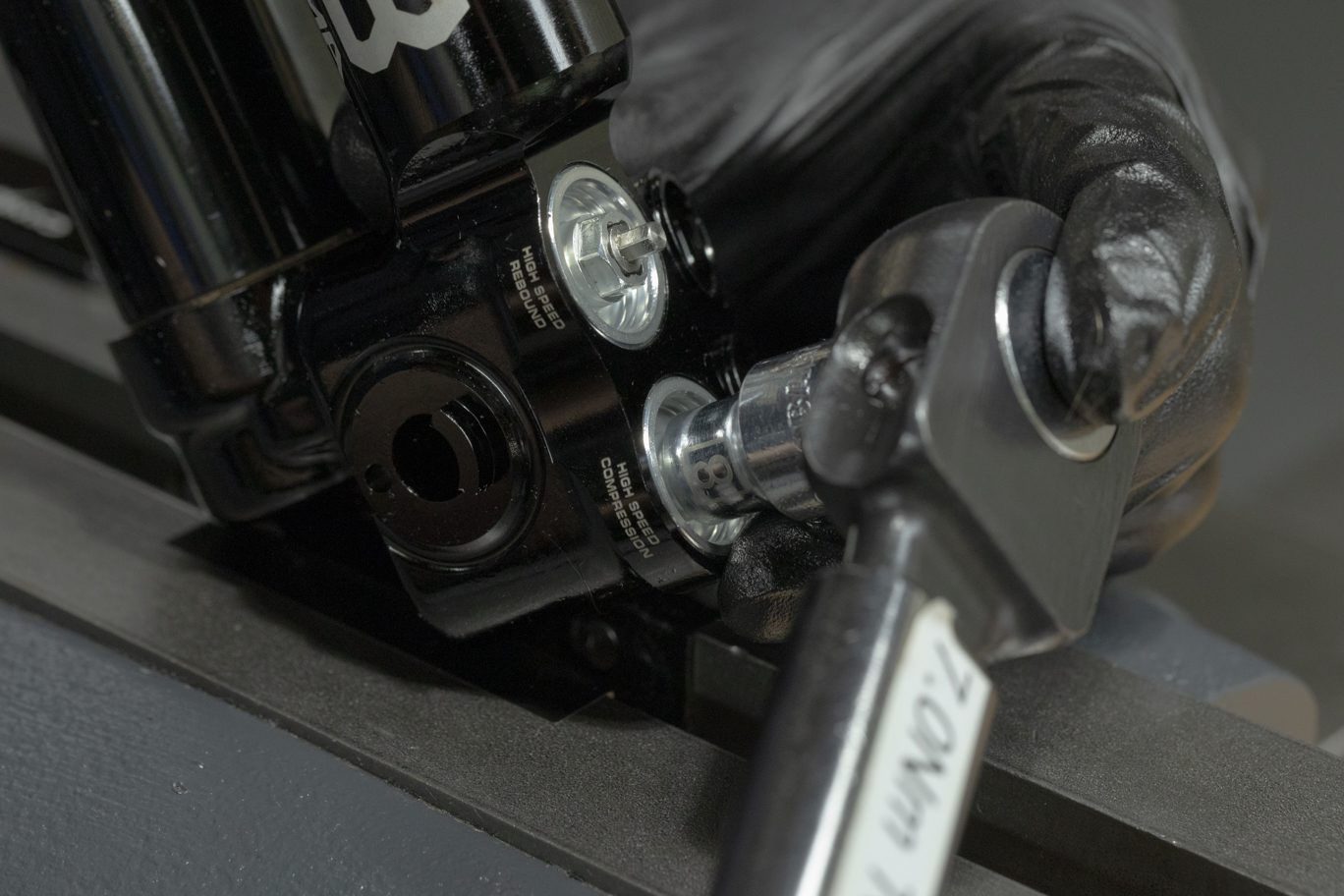

Step 4 – High Speed Adjuster Housing Install

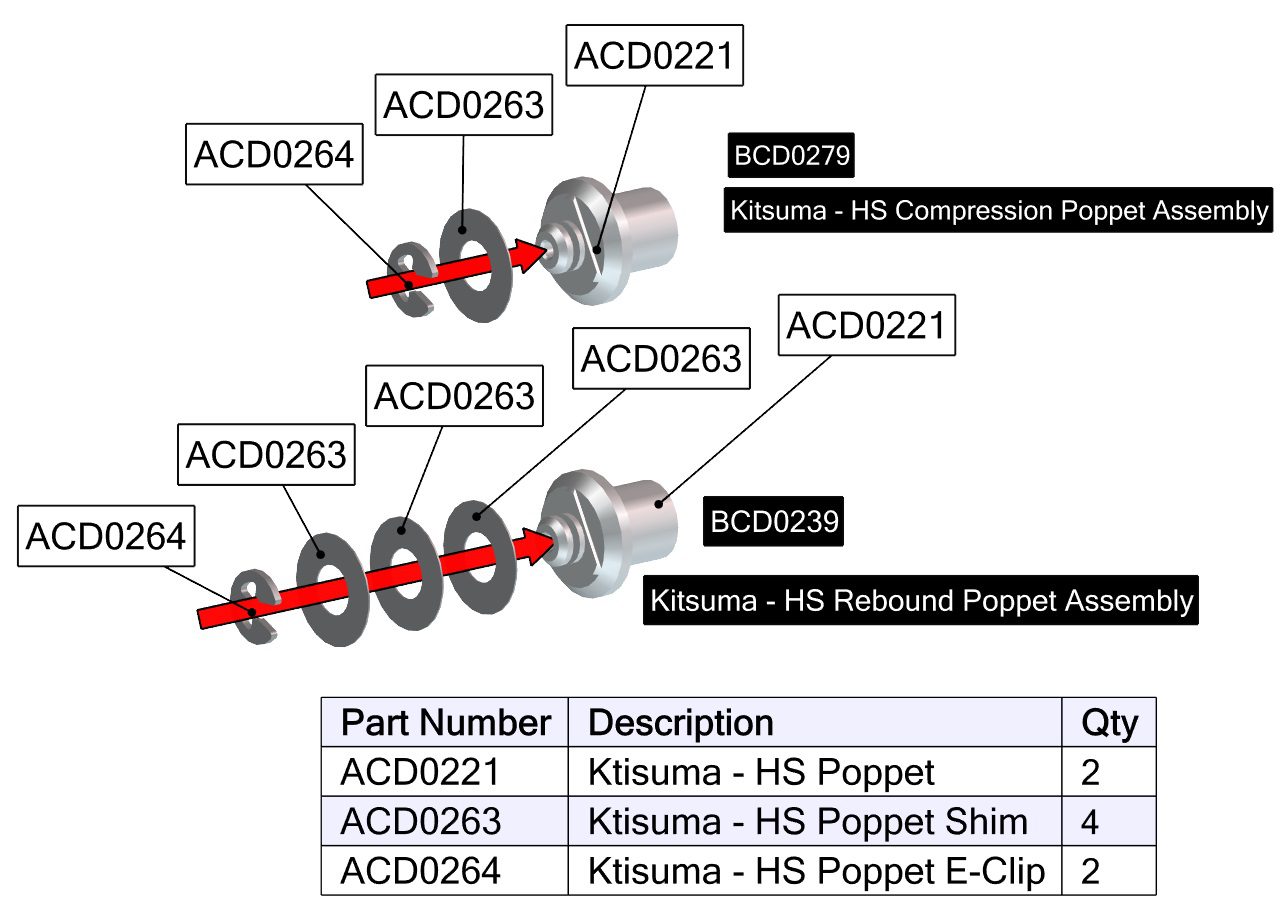

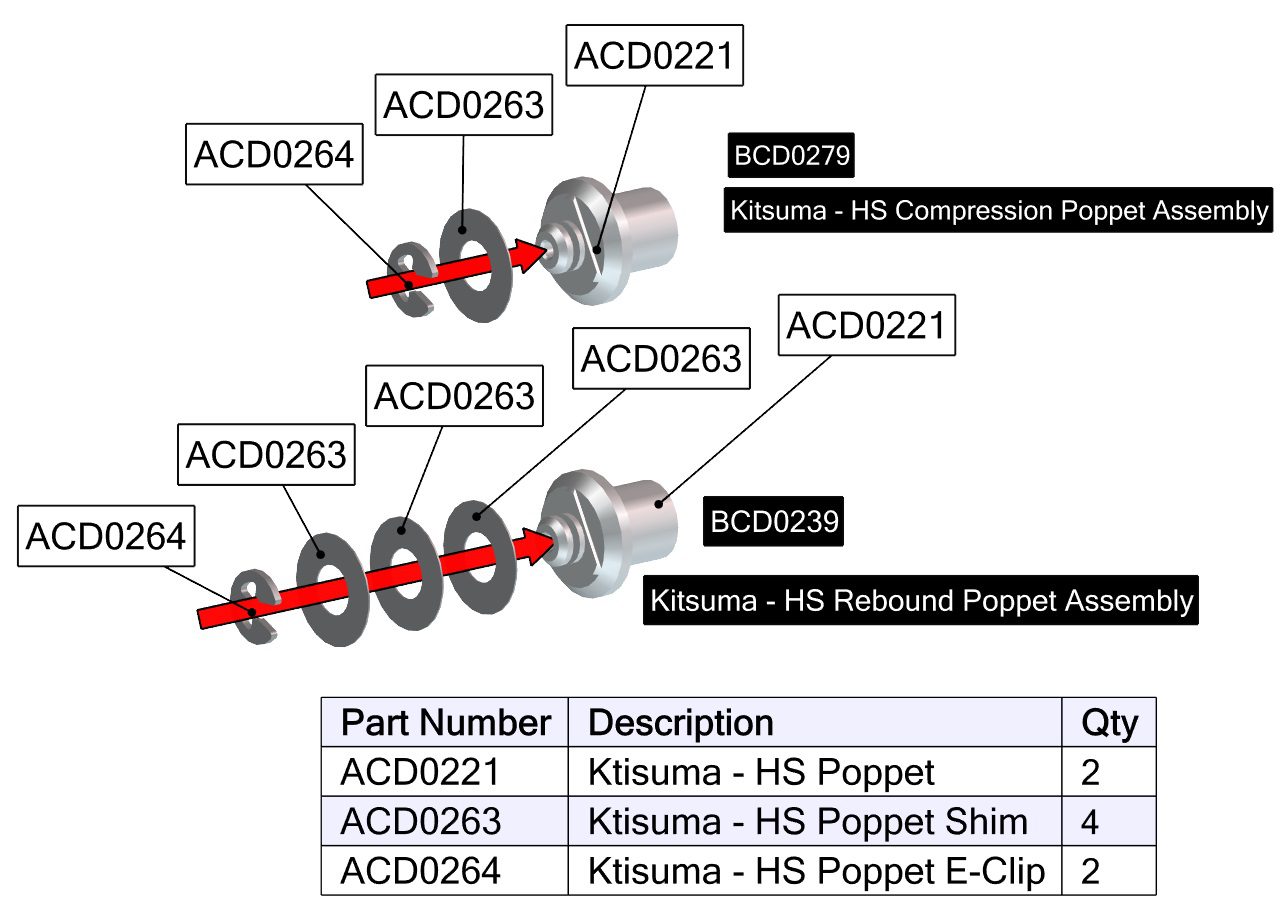

Install poppet assembly with shims towards valve body followed by poppet spring. Note rebound gets the stronger (40w) poppet spring and has 3 shims on poppet; compression has lighter (20w) spring and 1 shim. Using an 8mm socket, torque to 7 Nm.

TSB039 – Kitsuma High Speed Cap (ACD0275) Loctite Removal from Installation

Rebound Spring & Poppet

Compression Spring & Poppet

Compression & Rebound Spring & Poppet

Exploded High Speed Poppets

Rebound Spring & Poppet on Adjuster

Rebound Adjuster Assembly Install 1

Rebound Adjuster Assembly Install 2

Rebound Adjuster Assembly Install 3

Compression Spring & Poppet on Adjuster

Compression Adjuster Assembly Install 1

Compression Adjuster Assembly Install 2

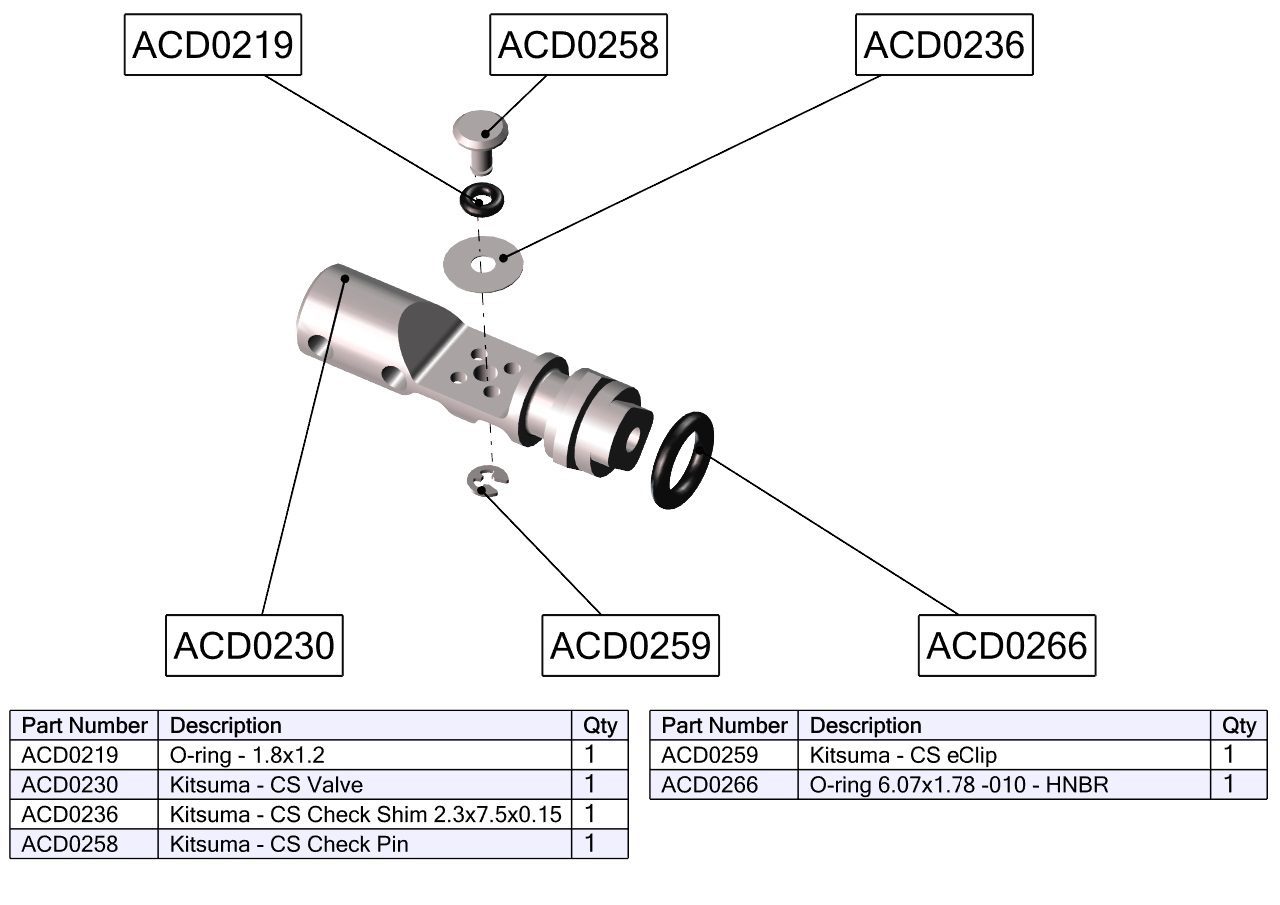

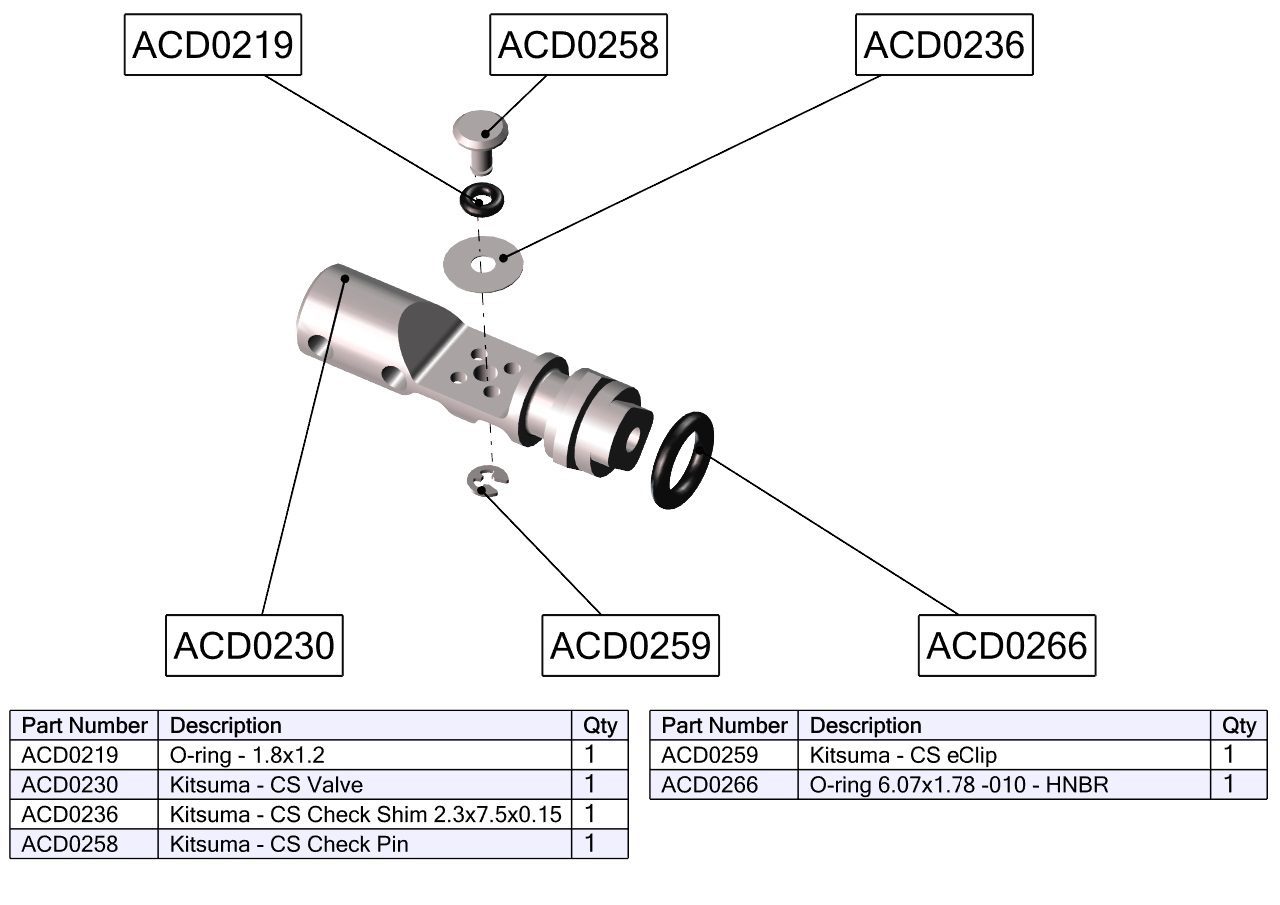

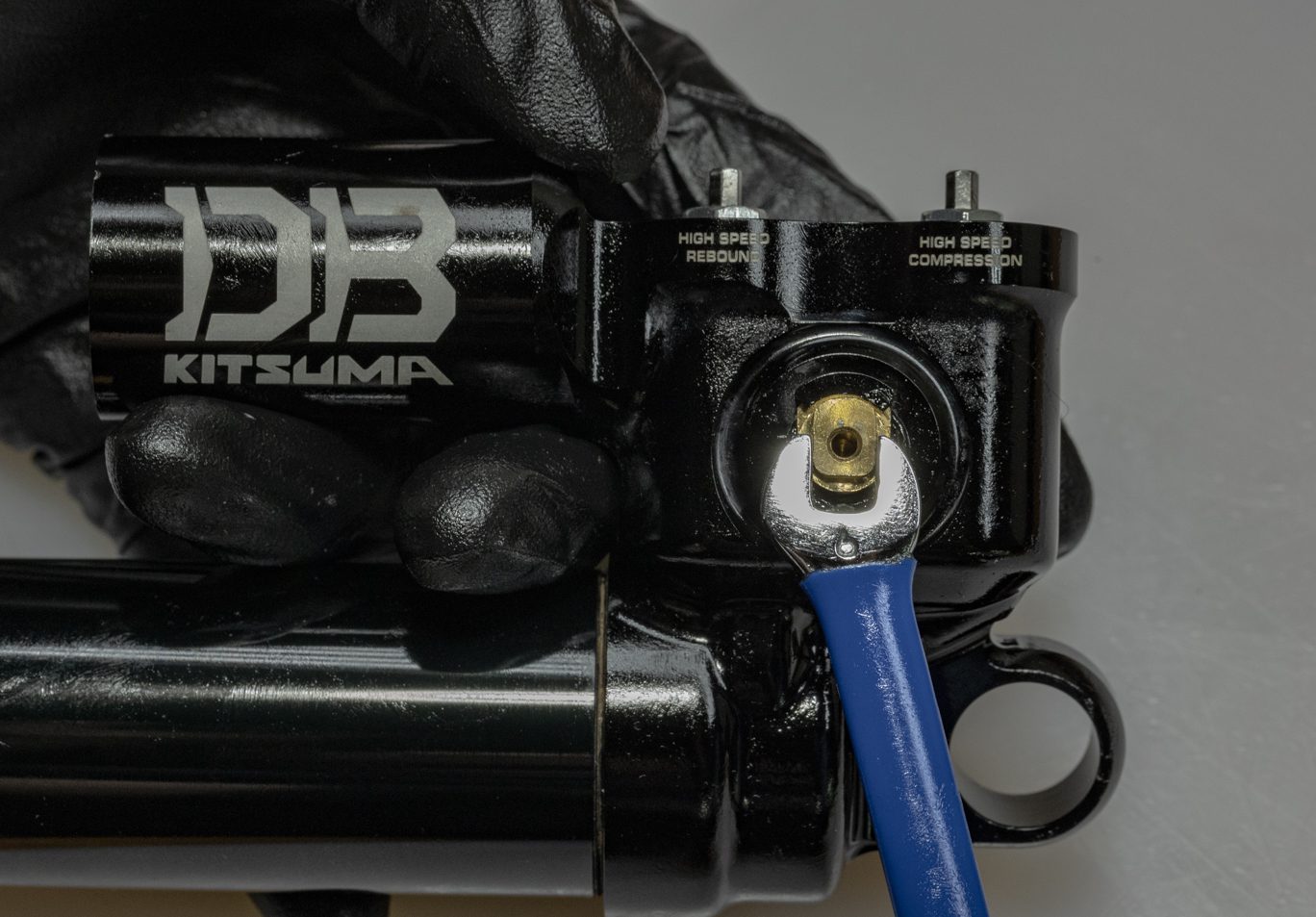

Step 5 – Climb Switch Spool Valve Install

Light grease and install Climb Switch valve o-ring (ACD0266). IL CS bullet (AAD1454) can be used here. Apply grease to Climb Switch valve on valve body and to Climb Switch valve. Insert valve into valve body with tab at 3:00. Once engaged, rotate CS valve tab underneath valve body tab.

CS Spool Valve O-Ring Install 1

CS Spool Valve O-Ring Install 2

CS Spool Valve O-Ring Installed

Exploded Climb Switch Spool Valve

Greasing Valve Body

CS Spool Valve Install

CS Spool Valve Clocking

CS Spool Valve Properly Clocked

Climb Switch Detent Install

Climb Switch Detent Installed

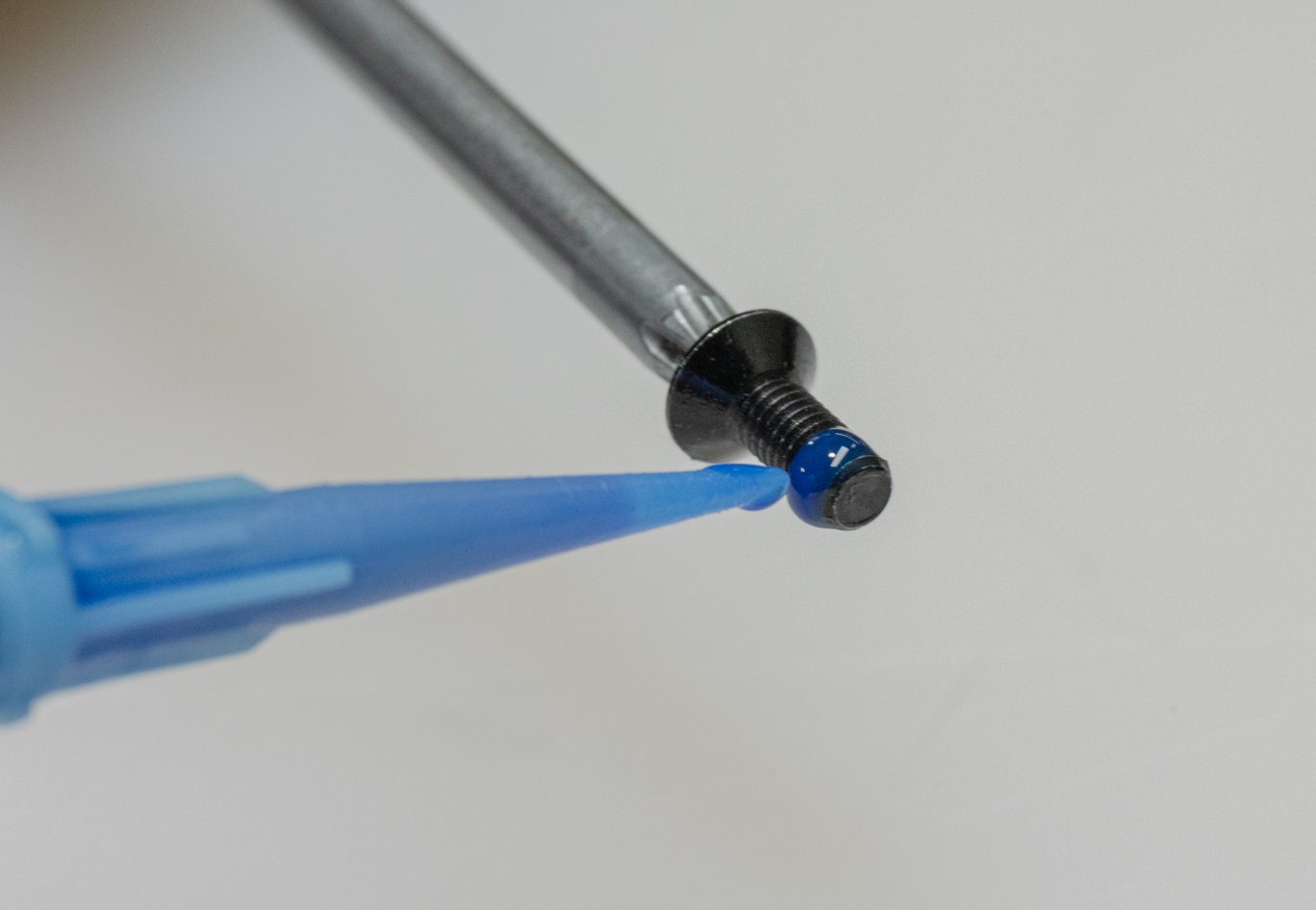

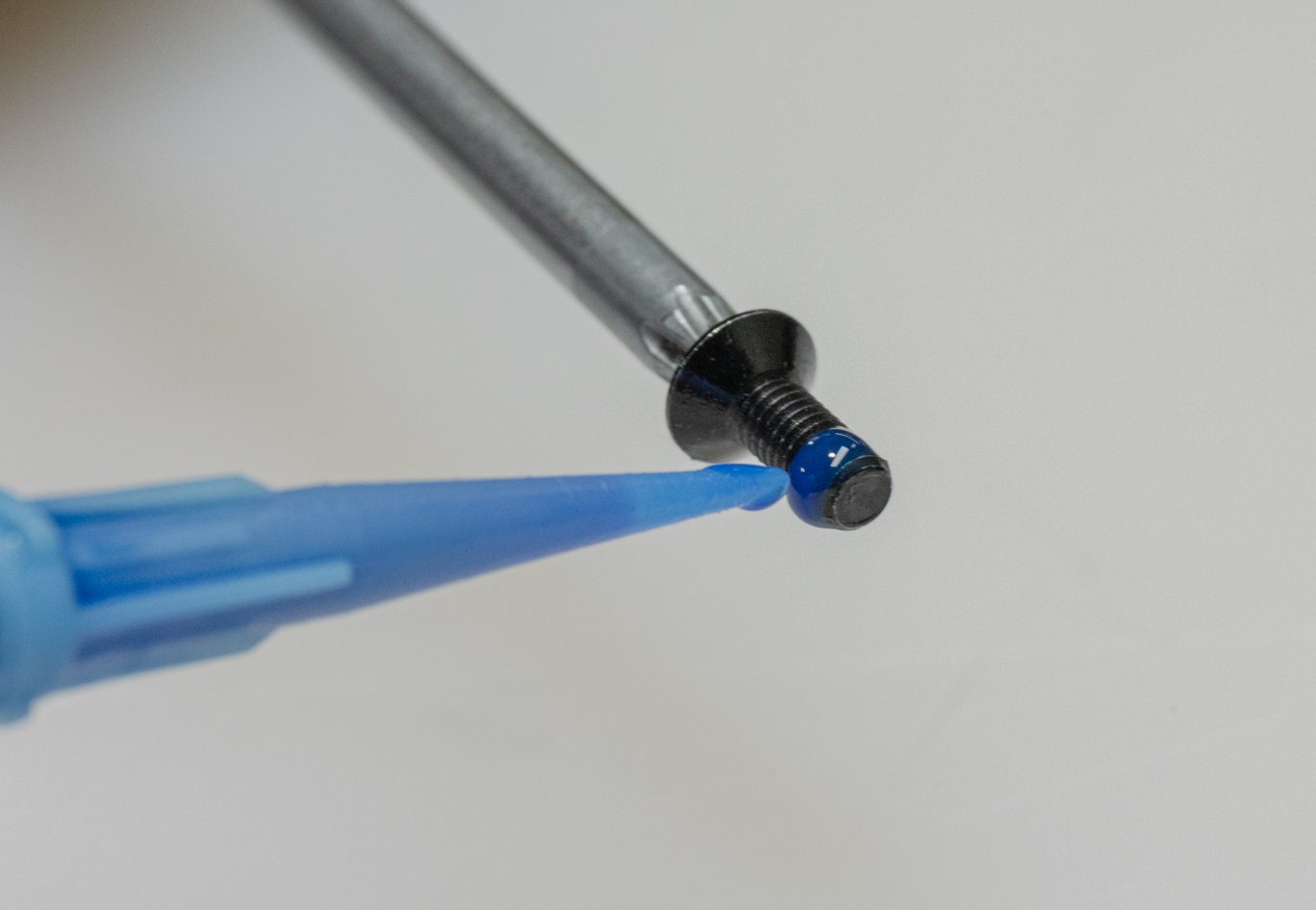

Step 6 – Climb Switch Lever Install

Light grease and install Climb Switch o-ring (AAD0800) on back side of lever. Place lever onto Climb Switch valve with lever at 9:00. Note that proper orientation of lever and valve required for proper interface. Apply blue Loctite (243) to Climb Switch mounting bolt. Secure CS lever with bolt. Torque to 1.2 Nm with T10.

Climb Switch O-Ring Install

Climb Switch O-Ring Installed

Climb Switch Proper Alignment

Climb Switch Installed

Climb Switch Mount Screw Prep

Climb Switch Mount Screw Install

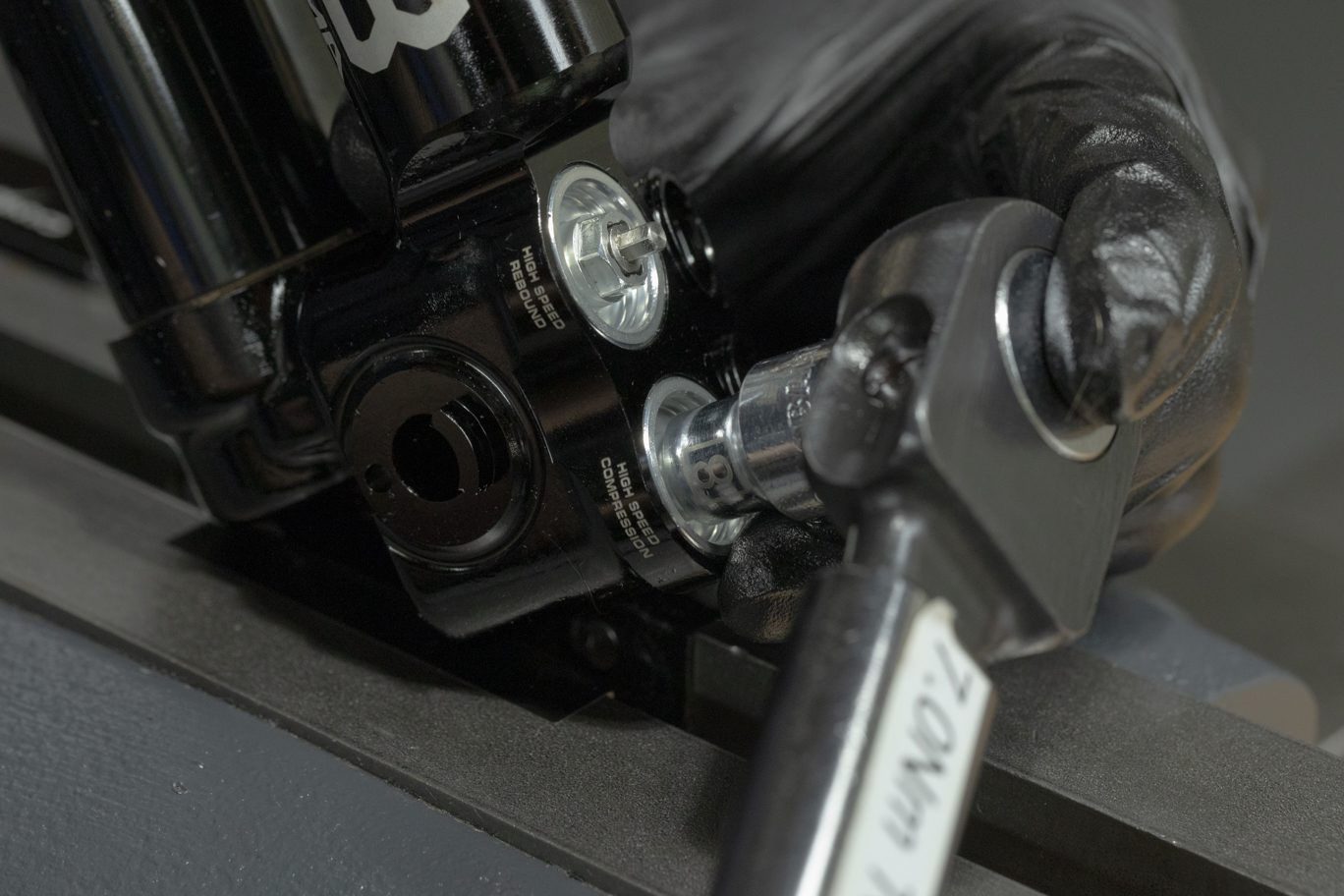

Step 7 – High Speed Dials Install

Lightly grease and install high speed adjustor dial o-rings (ACD0276) on back of dial. Fully open (counterclockwise) high speed controls and install dial with indicator in the 1:00 to 3:00 range as allowed by the interface.

High Speed Dial O-Ring Install

High Speed Rebound Dial Install

High Speed Compression Dial Install

High Speed Rebound Dial Seating

High Speed Compression Dial Seating

High Speed Dials Installed

Step 8 – Low Speed Dials Install

Lightly grease and install low speed adjustor dial o-rings (ACD0254) on back of dial. Apply thin layer of grease to the valve/dial interface on the valve body. Check that low speed controls are fully closed (clockwise). Line up dial at 6:00. Rotate dial and valve counterclockwise while applying gentle pressure until the dial seats onto the valve.

Low Speed Dial O-Ring Install

Greasing Low Speed Compression Valve Body

Greasing Low Speed Rebound Valve Body

Low Speed Compression Dial Install

Low Speed Compression Dial Rotation

Starting with Low Speed at 6:00

Low Speed Rebound Dial Rotation

All Dials Installed

Step 9 – Reservoir Bladder & End Cap Install

If updating from older IFP system, a new reservoir end cap (BCD0169) is required.

Grease all three sides of the quad ring portion of bladder.

Work bladder onto reservoir cap. Insert end cap/bladder assembly into reservoir. Apply pressure to fully seat and expose circlip channel. Install circlip. Back end cap out against circlip using bladder fill tool or IFP setting tool.

TSB045 – Kitsuma IFP Changed to Bladder

Greasing Bladder Quad Ring, Side 1

Greasing Bladder Quad Ring, Side 2

Greasing Bladder Quad Ring, Side 3

Installing Bladder on Res End

Bladder & Res End Assembly Install 1

Bladder & Res End Assembly Install 2

Seating Bladder & Res End

Installing Res End Circlip

Res End Circlip Installed

Backing Res End Against Circlip

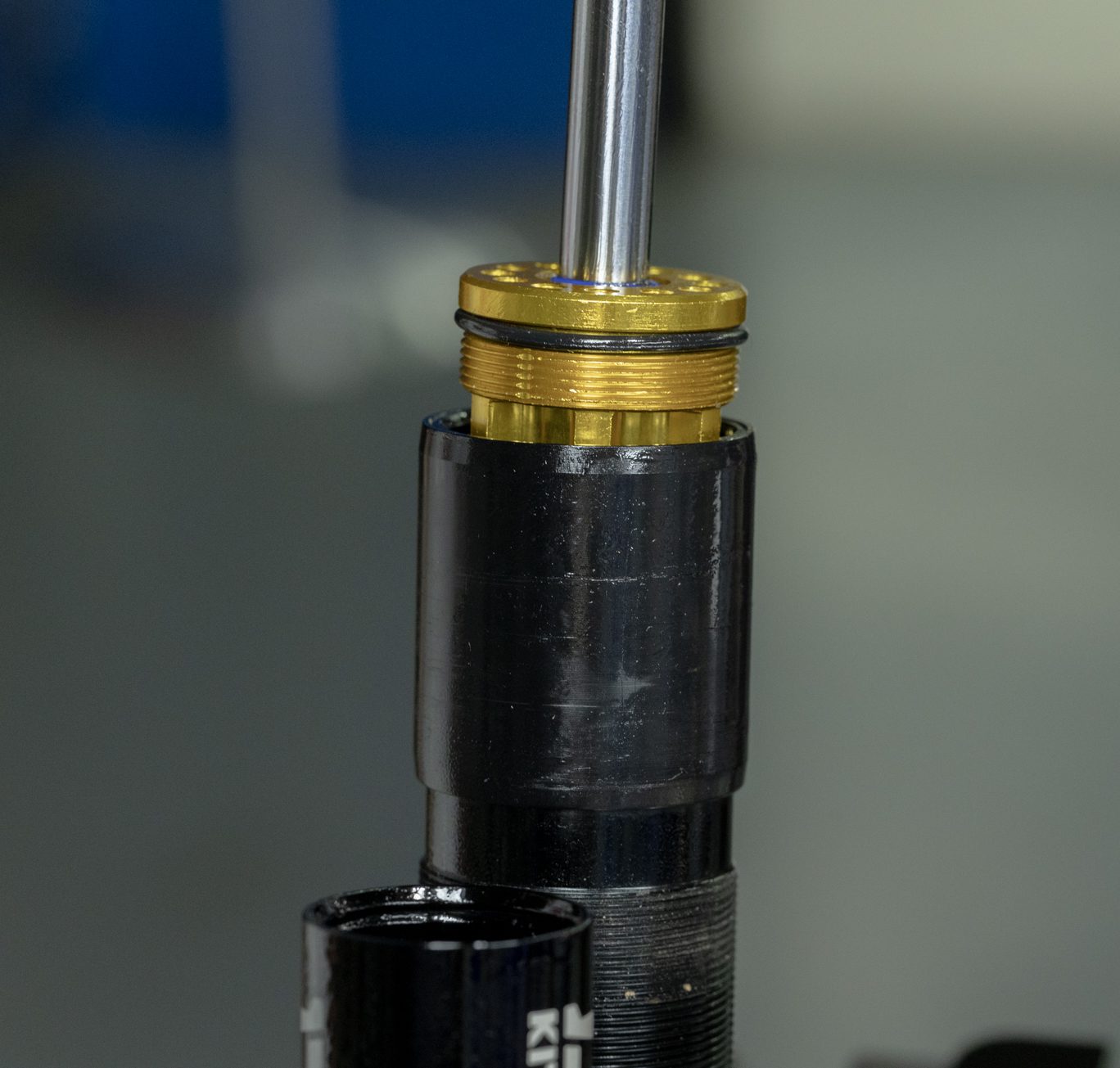

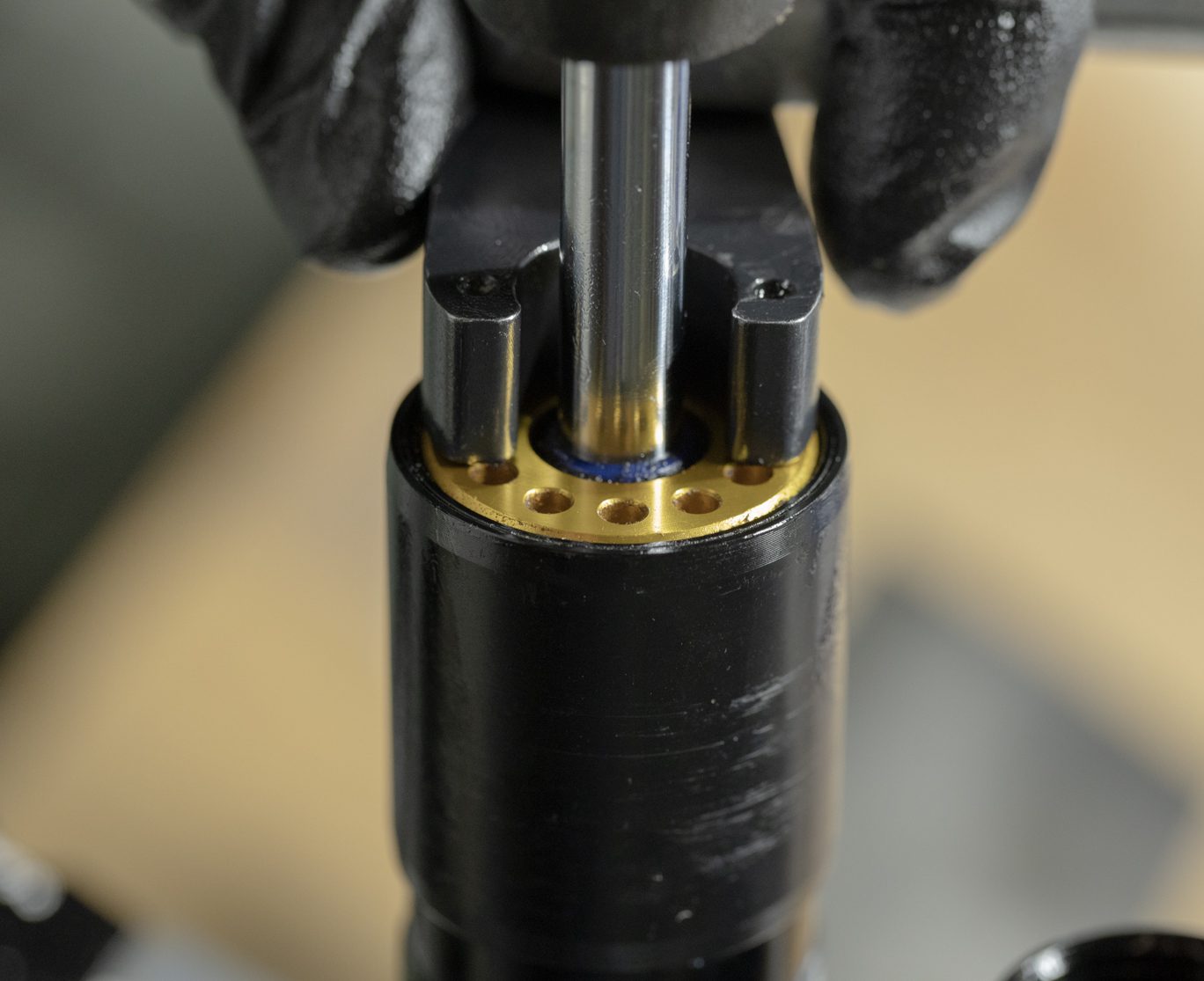

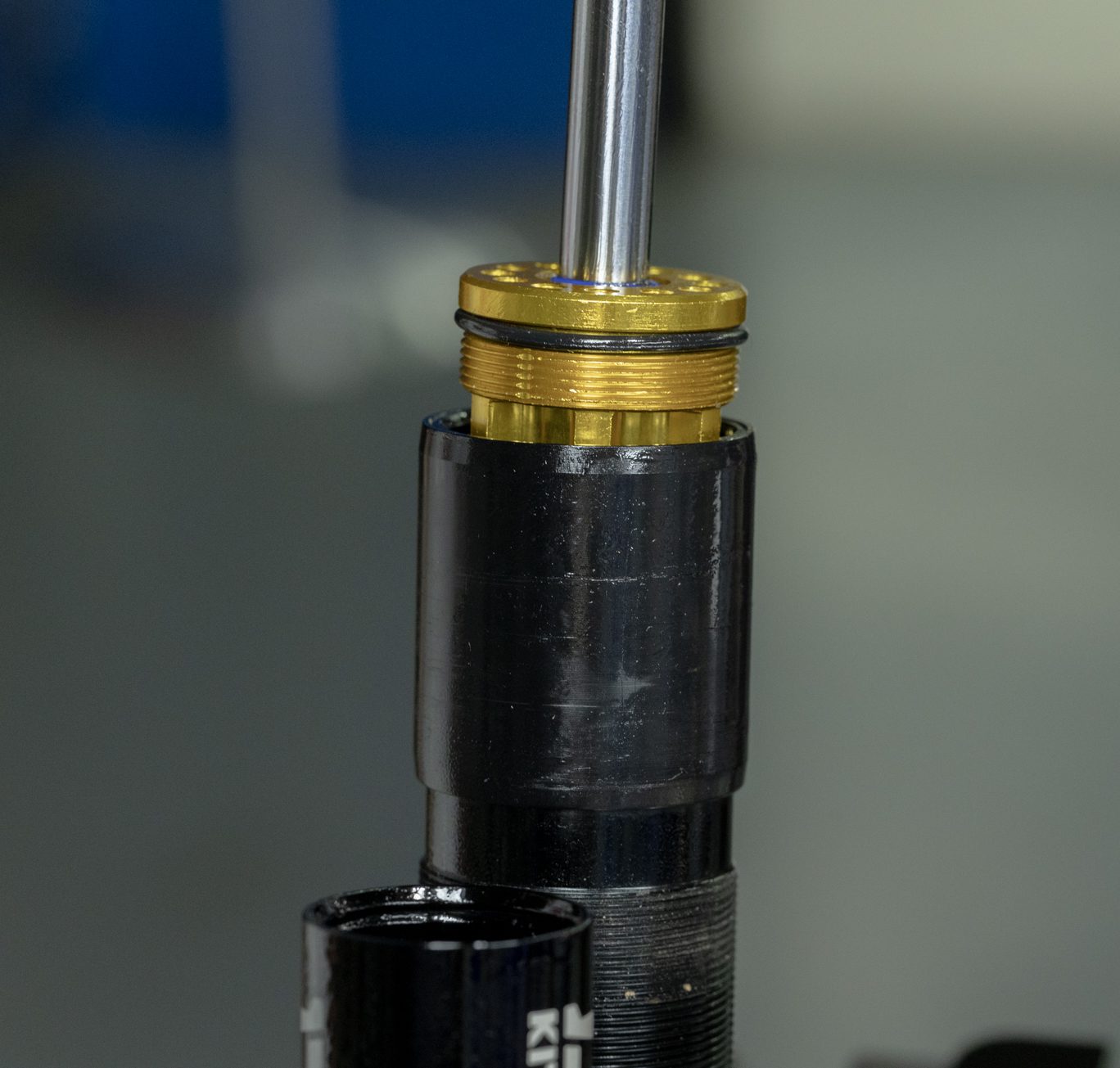

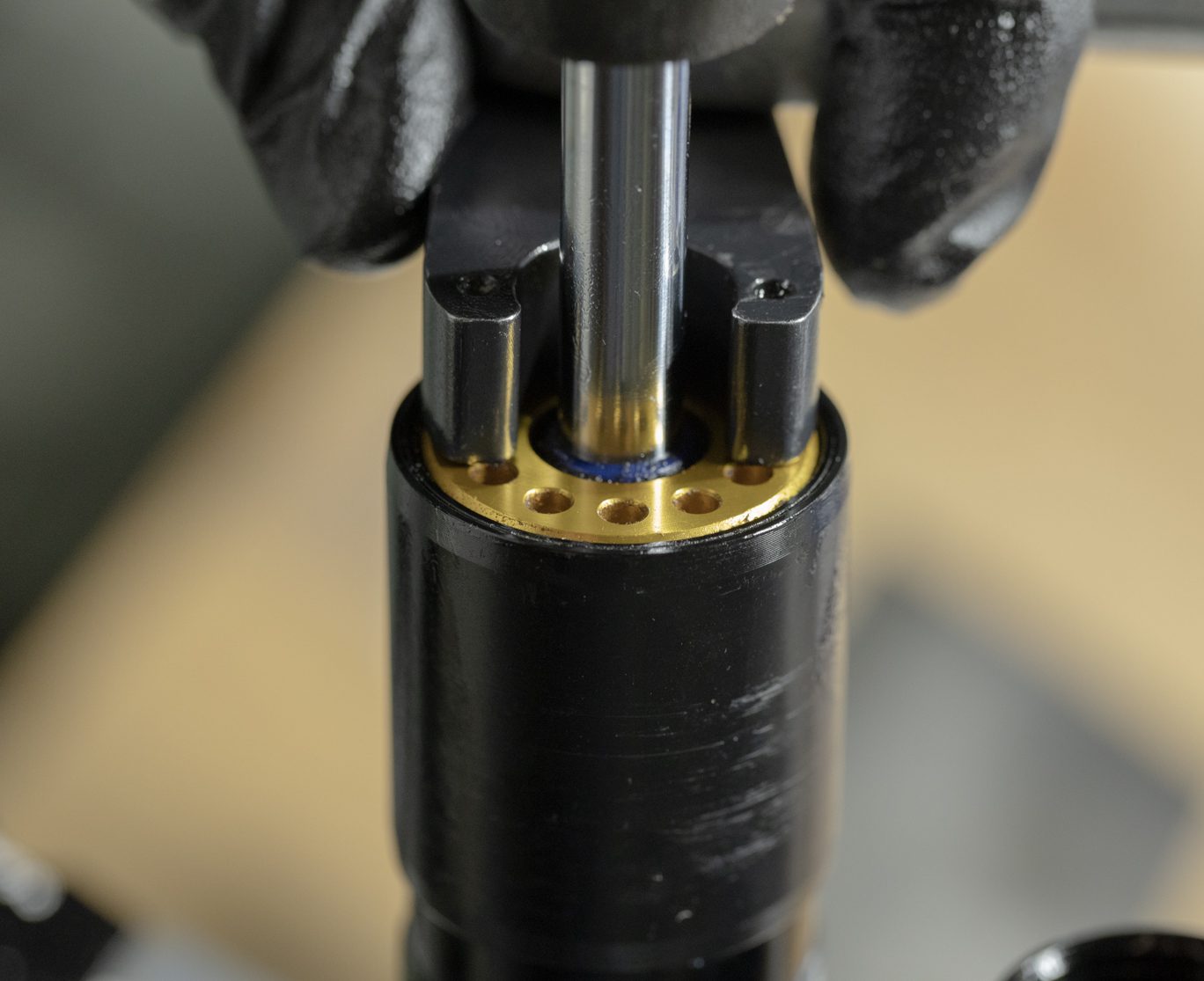

Step 10 – Oil Seal Head & Shaft Assembly Install

Coat piston band with shock oil. Work piston into inner damper tube. Insert inner damper tube/oil seal head assembly into outer damper tube. Thread oil seal head onto outer damper tube. Torque to 22 Nm with Oil Seal Head tool.

TSB048 – Kitsuma Oil Seal Head Torque Valve

Coating Piston Band (air seal head shown)

Coating Inner Damper Tube (air seal head shown)

Oil Seal Head & Shaft Assembly Install

Inserting Oil Seal Head Spanner

Oil Seal Head Spanner Seated

Torquing Oil Seal Head

Torquing Oil Seal Head

Continue to Part 4

Next