DBKitsuma Air Complete 100 & 200 Hour Service Instructions (Part 1 of 4)

Mar 2022 orig., Jul 2023 rev.

Table of Contents

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek shocks have pressurized nitrogen and oil, even coil shocks. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service.

Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a shock still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

These service instructions cover the basic service procedures using standard service kits. If your suspension requires parts beyond standard replacement parts – shaft, damper tubes, end eyes – please consult your authorized Cane Creek service center or contact us at our Cane Creek Support Center.

Service Notes

The Kitsuma Air and Coil share many service steps. Additionally, the Standard and Trunnion variants of both models have identical service procedures other than where to clamp the cylinder head. Some images in these instructions may not be identical to the valve body or outer damper tube on the Kitsuma Air, but process is the same for the shock in the image and the shock on your bench.

100 vs. 200 hour service

The only difference between the 100 hour service and the 200 hour service is whether to service or replace the Air Oil Seal Head and the Main Oil Piston. At 100 hours, those can be cleaned, serviced and reinstalled. At 200 hours, they should be replaced. If uncertain on hours, check for wear on the dual bushings inside the Air Oil Seal Head and on the piston band on the Main Oil Piston. When in doubt, replace both.

Service Kits

BCD0337 – Kitsuma Air Complete 100 Hour Rebuilt Kit (w/ Bladder)

OR

BCD0339-01 – Kitsuma Air Complete 200 Hour Rebuild Kit (w/ Bladder) – includes new Air Oil Seal Head & Main Oil Piston

BCD0169 – Bladder Res End Cap (if replacing older IFP system)

Required Cane Creek Tools

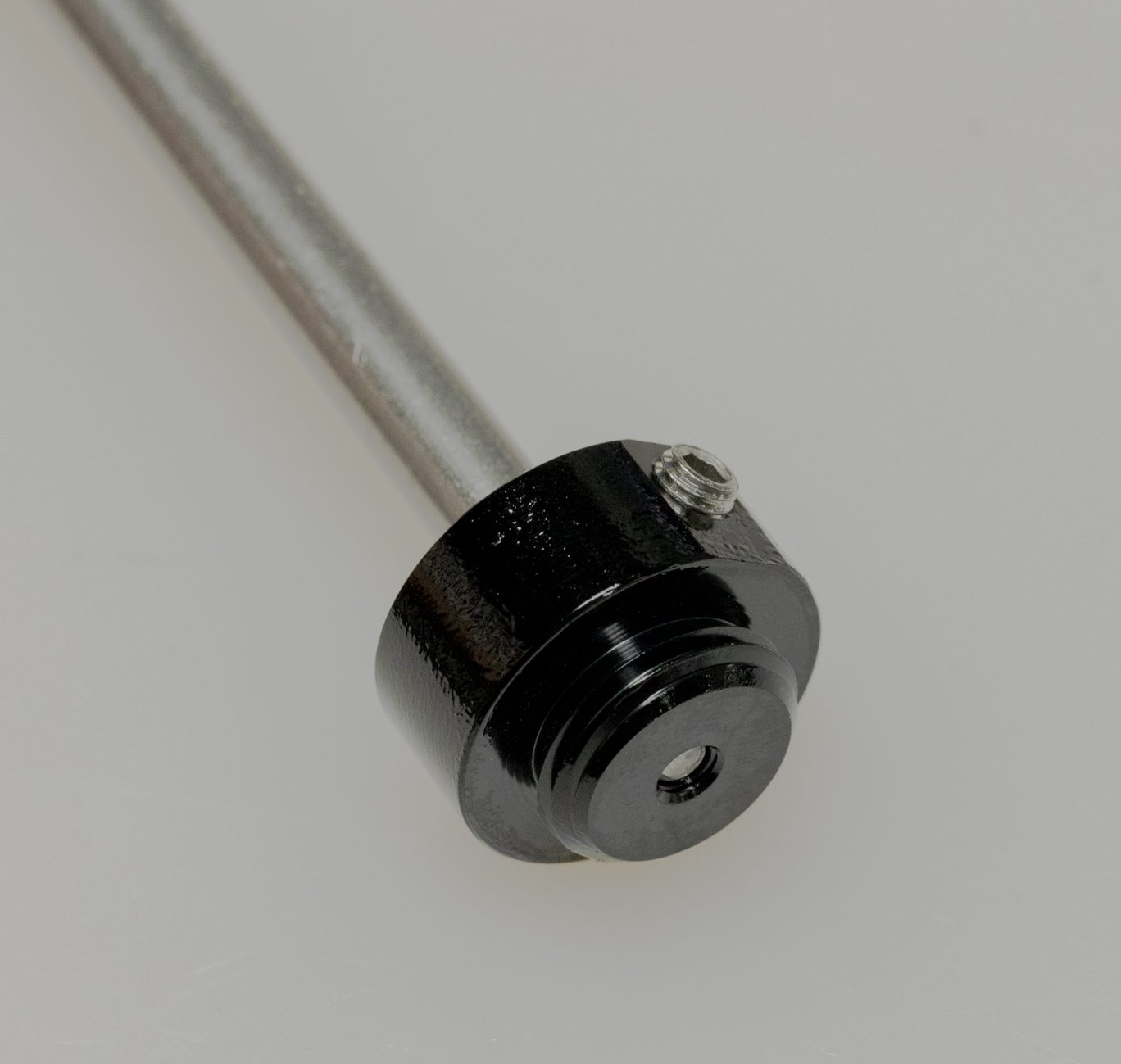

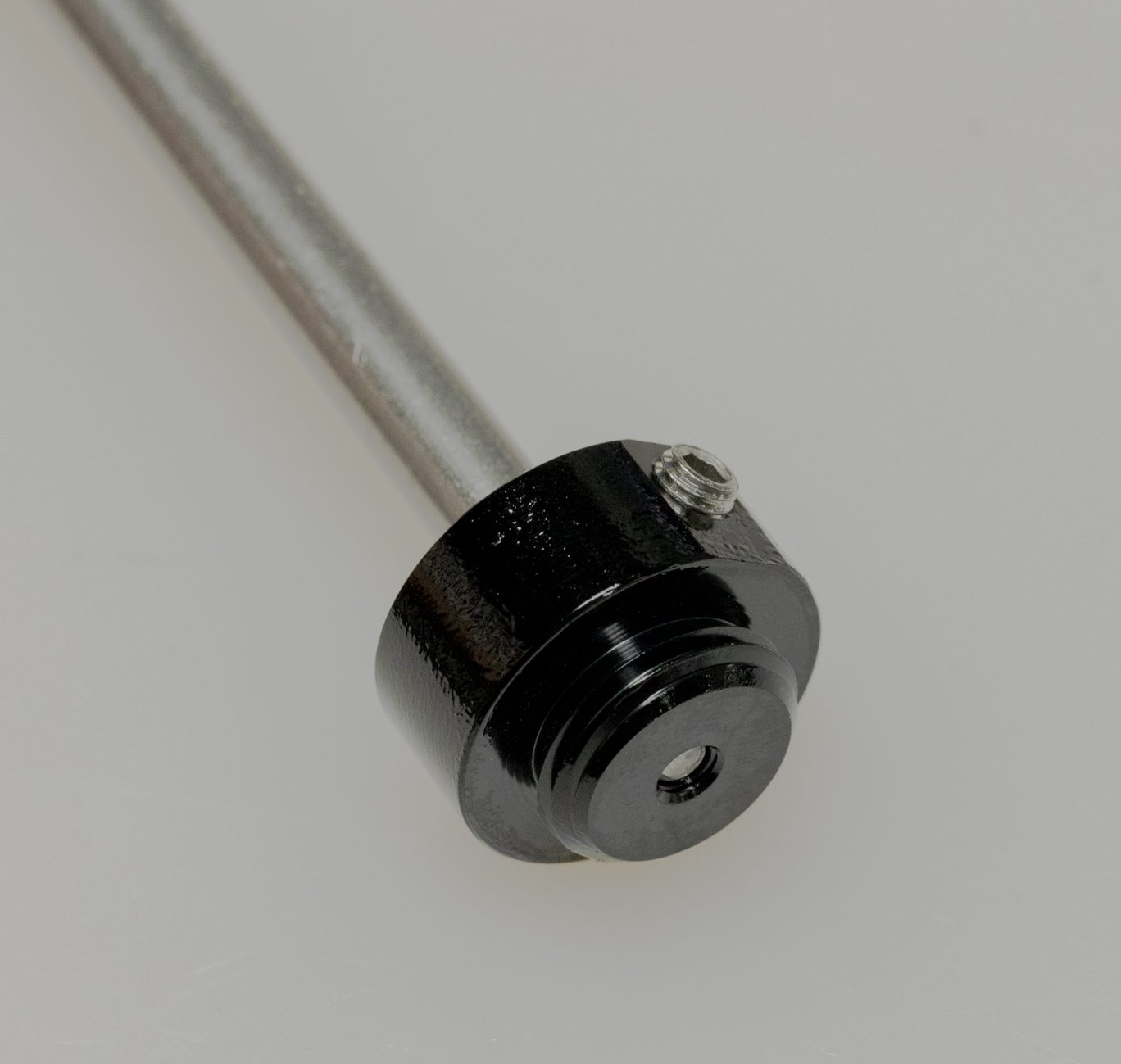

ACD0354 – Bladder Res End Fill Tool

AAD1361-01 – DBCoil/ DBAir – Oil Fill Needle Adapter

DBT016 – DB Gas Fill Needle

AAD0555 – 8mm & 9.5mm Shaft Clamp

AAD2465 – Kitsuma Valve Seat Tool

ACD0322 – Kitsuma Low Speed Detent Funnel

BAD1298 – DB 9.5mm Shaft Bullet

ACD0334 – Kitsuma Air Oil Seal Head Tool

BCD0344 – Kitsuma/DBair/DBair IL Air Seal Head Tool

DBT012 – DB IFP Setting Tool

Additional Tools & Supplies

Allen wrenches – 3 & 4mm

Torx wrenches – T10 & T20

Sockets – 4, 8 & 13mm

Crowfoot wrenches – 1/2″ & 32mm

9.5mm Shaft Bullet

Torque wrenches

Knipex pliers

Pick

Strap wrench

Suspension Grease

PolyLube Grease

Motorex 4wt Racing Fork Oil

Royal Purple 10w-30

Vacuum Oil Fill Machine

Nitrogen Fill System

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

| Shaft Bolt | 5 Nm | 243 (Blue) |

| Outer Damper Tube | Tight | 263 (Red) |

| Valve Seat | 4.8 Nm | None |

| High Speed Adjuster | 7 Nm | None |

| Climb Switch Screw | 1.2 Nm | 243 (Blue) |

| Oil Seal Head | 22 Nm | None |

| End Eye | 4.8 Nm | 243 (Blue) |

| Inner Air Can/Air Seal Head | 22.6 Nm | None (PolyLube) |

Oil Chart

| Oil Location | Oil Type | Oil Amount |

|---|---|---|

| Air Can | Royal Purple 10w-30 | 5 mL |

| Damper Fill | Motorex 4wt Racing Fork Oil | Fill to 3 Bars |

Nitrogen Chart

| Nitrogen Location | Nitrogen Pressure |

|---|---|

| Valve Body | 11 - 12 Bars |

General Prep

Clean shock. Record tune if desired. Remove hardware. Remove bushings if replacing. Remove valve cap. Bleed air from shock using shock pump. Be sure to depressurize shock slowly to avoid trapping air in the negative chamber.

Hardware & Bushing Removed

Clamped for Disassembly

Pump Attach

Air Bleed

Air Can Disassembly

Step 1 – Outer Air Can Removal

Pinch & remove air can retaining o-ring. Clamp shock in soft jaw vise. Using strap wrench, turn air can and pull down away from air seal head. Unclamp shock. Remove air can. Note and remove any air volume reduction.

Air Can Retaining O-Ring Removal

Air Can Retaining O-Ring Removed

Strap Wrench on Air Can

Air Can Removal

Volume Reduction Removal

Outer Air Can Removed

Step 2 – Freeing Inner Air Can & Air Seal Head

Reclamp shock. Align teeth on Air Seal Head Tool (BCD0344) with grooves on air seal head. Unthread air seal head and inner air can from end eye. Splash oil may be present. Gently clamp inner air can and use air seal head tool to loosen air seal head from inner air can. Take care to not crush inner air can.

Air Seal Head Tool on Air Seal Head

Loosening Air Seal Head & Inner Air Can

Inner Air Can Freed from End Eye

Gently Clamping Inner Air Can

Loosening Air Seal Head from Inner Air Can

Air Seal Head Removed from Inner Air Can

Step 3 - End Eye Removal

Option 1 (pictured):

Clamping valve body, use 4mm Allen insert into end eye and 1/2″ crowsfoot, loosen end eye from shaft.

Option 2 (not pictured):

Using shaft vise, clamp shaft between end eye and air can. Use 1/2″ crowsfoot to loosen end eye from shaft.

Remove and discard air can and shaft o-rings from end eye. Remove any stroke/volume reduction and bottom out bumper.

Always use extreme caution when using a pick in this step or others to avoid scratching metal parts. Failure to do this can create scratches in the o-ring glands which cause leak paths for oil or gas. When possible, pinch and remove o-rings rather than using a pick.

Loosening Shaft from End Eye 1

Loosening Shaft from End Eye 2

Unthreading Shaft from End Eye

Removing Air Can O-Ring from End Eye

Removing Shaft O-Ring from End Eye

Volume/Stroke Reduction & Bottom Out Bumper

Step 4 – Inner Air Can Removal

Slide off inner air can. Remove inner air can o-rings and discard. Inspect inner air can for wear. Replace if necessary. Note that anodization rack marks are normal and do not impact shock performance.

Inner Air Can Removal

Inner Air Can Removed

Inner Air Can O-Ring Removal

Air Spring Disassembled

Damper Disassembly

Step 1 – Nitrogen Bleed & Oil Removal

***Use caution as nitrogen is pressurized.***

Remove reservoir end cap screw using T20. Remove and discard o-ring. Use gas fill needle to bleed nitrogen from reservoir tube. Temporarily reinstall end eye on shaft. Remove oil fill screw with T20. Cycle the shaft to remove as much oil as possible from the damper. Dispose of oil properly. Remove end eye.

Res End Cap Fill Screw Removal

Res End Cap Fill Screw Removed

Res End Cap Fill Screw O-Ring Removed

Bleeding Nitrogen

End Eye Reinstall

Oil Fill Screw Removal

Oil Drain 1

Oil Drain 2

Oil Drain 3

Step 2 – Oil Seal Head & Air Piston Removal

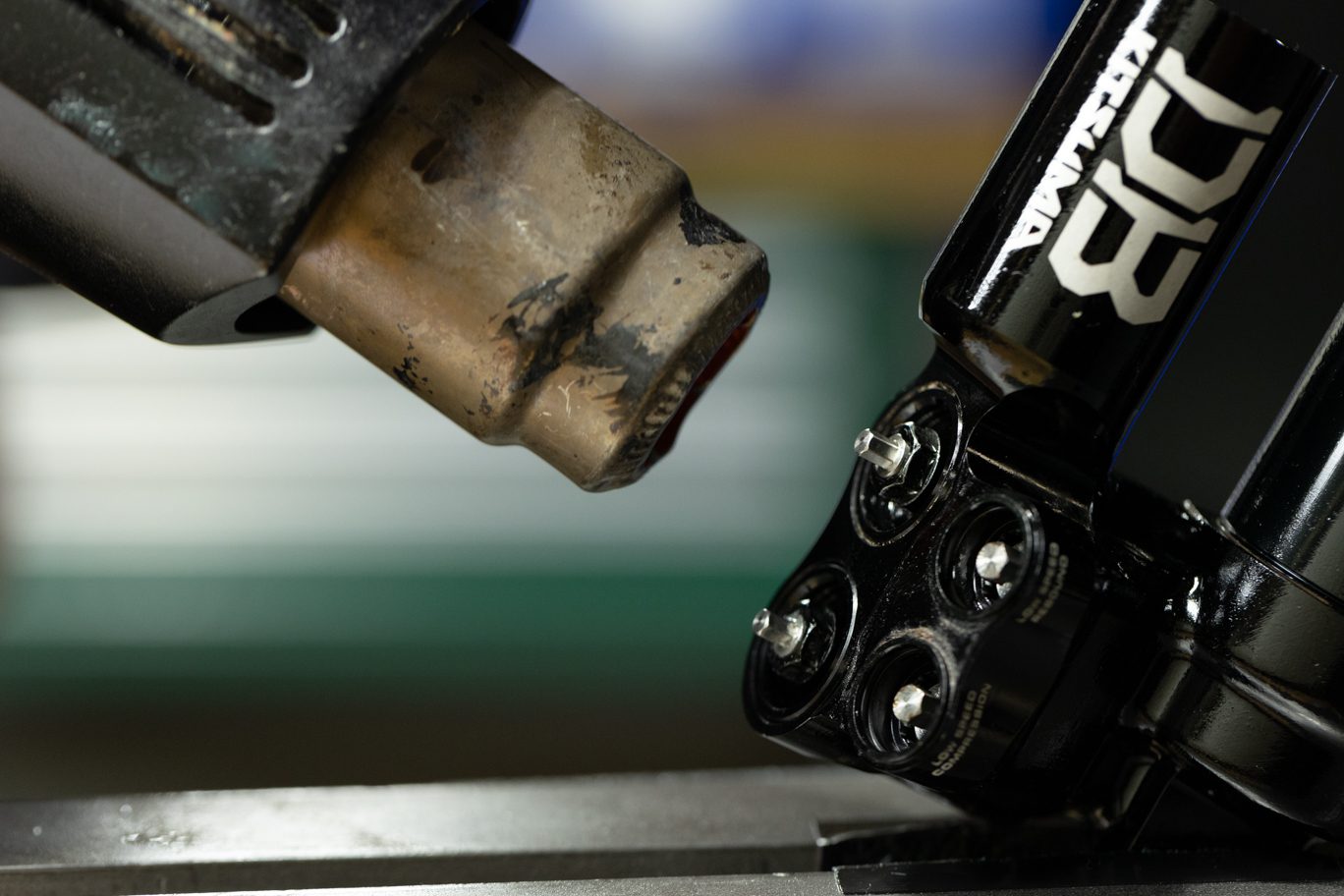

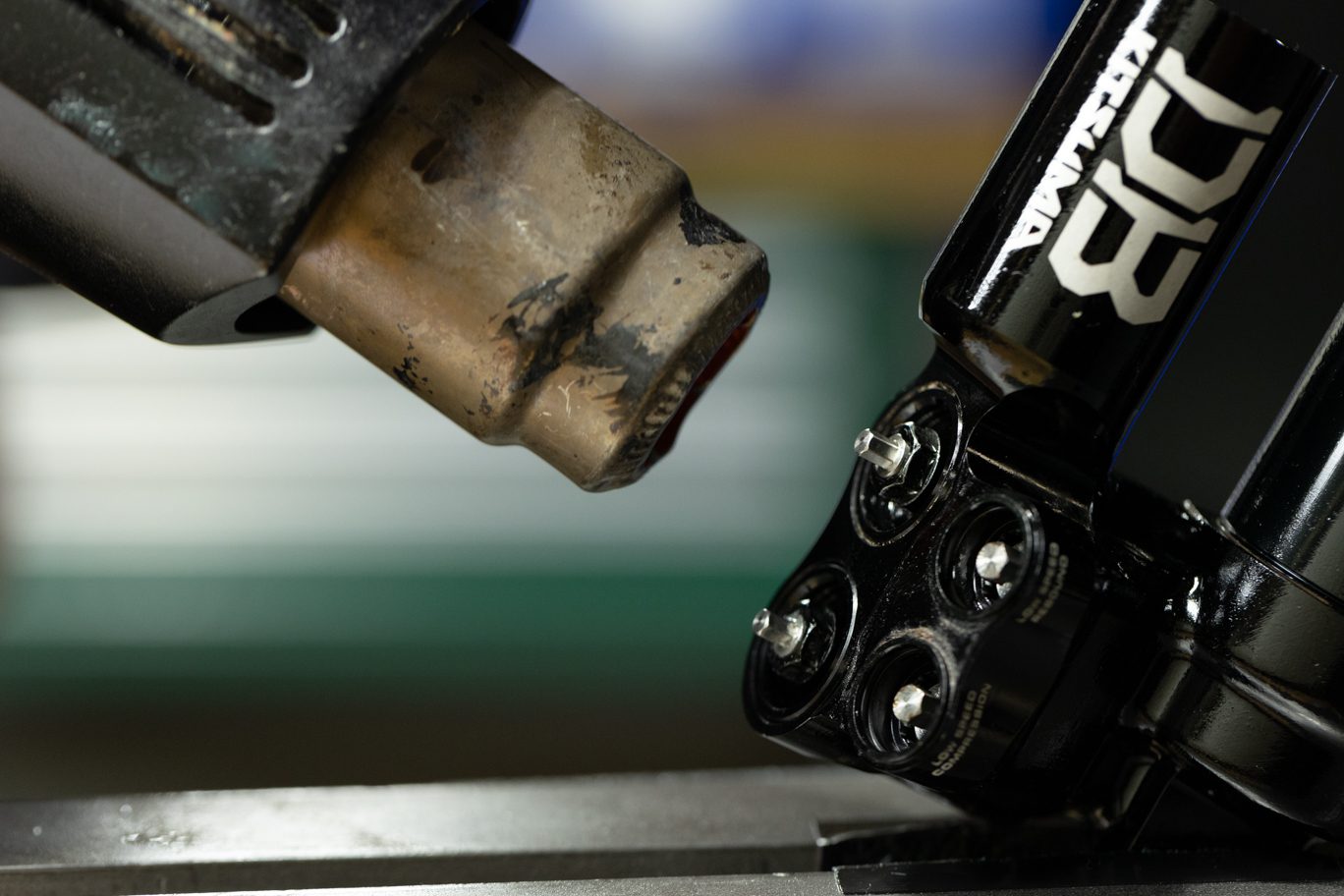

Clamp valve body into vise. Using Air Oil Seal Head tool (ACD0334) with 32mm crowsfoot, loosen and remove oil seal head/air piston.

Clamped for Oil Seal Head/Air Piston Removal

Oil Seal Head/Air Piston Tool

Crowsfoot on Oil Seal Head/Air Piston Tool

Loosening Oil Seal Head/Air Piston

Oil Seal Head/Air Piston Freed

Oil Seal Head/Air Piston Removed

Step 3 – Inner Damper Tube Removal

Inner damper tube should come out with air piston. If not, reinstall piston and use rotational movement to free damper tube. Inspect inner damper tube for piston wear. Replace if necessary.

Inserting Air Piston

Removing Inner Damper Tube w/ Air Piston

Inspecting Inner Damper Tube

Step 4 – Air Seal Head Disassembly

Remove negative volume reducers if present (225 Trunnion and 250 standard do not have these). Remove air seal head. Remove and discard sag o-ring. Pour out any remaining damper oil. From air seal head, remove wiper seal, L-rings, quad ring and outer o-ring.

Neg Volume Reducer Removal 1

Neg Volume Reducer Removal 2

Air Seal Head Removal

Sag O-Ring Removal

Discarding Remaining Oil

Air Seal Head Outer O-Ring Removal

Air Seal Head Wiper Removal

Air Seal Head First L-Ring Removal

Air Seal Head Quad Ring Removal

Air Seal Head Second L-Ring Removal

Step 5 – Air Oil Seal Head Removal

Remove air oil seal head and inspect. For 100 hour service, remove external o-ring & internal quad-ring and discard. For 200 hour service or if wear is present on dual bushings, discard the complete air oil seal head. Remove shaft spacer and top out bumper.

Air Oil Seal Head Removal

Shaft Spacer Removal

Top Out Bumper Removal

Step 6a – IFP Removal

Using IFP tool (DBT012), press cap into the reservoir tube exposing circlip. Press on circlip to remove from channel. Pick should not be required but could be used if needed. Thread IFP tool back into end cap, remove and discard. Thread IFP tool into metal IFP and remove from reservoir tube. Use adaptor for plastic IFP. Discard IFP.

TSB045 – Kitsuma IFP Changed to Bladder

Threading IFP Tool onto Res End Cap

Depressing Res End Cap

Freeing Res End Cap Circlip

Res End Cap Circlip Removed

Res End Cap Removed

Old IFPs, Metal vs. Plastic

Metal IFP Removal

Adapter for Removing Plastic IFP

Plastic IFP Removal

OR

Step 6b – Bladder Removal

Using bladder setting tool (ACD0354), press res end cap into reservoir, exposing circlip. Press on circlip to remove from channel. Pick should not be required but could be used if needed. Use IFP setting tool (DBT012) to pull end cap out of reservoir tube. If bladder does not come out with end cap, remove with pick.

TSB045 – Kitsuma IFP Changed to Bladder

Bladder Setting Tool

Bladder Setting Tool Attached to End Cap

Depressing End Cap

Freeing End Cap Circlip

End Cap Circlip Removed

Res End Cap Removed

Bladder Removal

Bladder Removed

Step 7 – Climb Switch & Spool Valve Removal

Using T10, remove Climb Switch mounting screw. Remove Climb Switch. Remove and discard Climb Switch o-ring. Remove CS detent. Turn CS valve so that the tab on the spool valve is no longer engaged with the valve body and remove assembly. Pinch & remove and discard spool valve o-ring.

Climb Switch Mounting Screw Removal

Climb Switch Removal

Climb Switch O-Ring Removal

Climb Switch O-Ring Removed

Climb Switch Detent Removal

Aligning Spool Valve for Removal

Spool Valve Removal

Spool Valve Removed

Spool Valve O-Ring Removal

Step 8 – Adjuster Dials Removal

Using Kinipex, gently grab outside edges of High and Low Speed adjuster tabs and remove. Place rag over adjusters to protect them (not shown in photo). Pinch & remove and discard adjuster o-rings.

HSC Dial Removal

HSR Dial Removal

LSC Dial Removal

LSR Dial Removal

Dial O-Ring Removal 1

Dial O-Ring Removal 2

Step 9 – High Speed Adjuster Housing Removal

Using 8mm socket, remove high speed adjuster housing. Apply heat to aid removal.

***Note high speed adjuster housing may also be silver.***

TSB039 – Kitsuma High Speed Cap (ACD0275) Loctite Removal from Installation

8mm Socket for Adjuster Housing

Applying Heat to Adjuster Housing

Adjuster Housing Removal

HSR Adjuster Housing Removed

HSC Adjuster Housing Removed

Step 10 – High Speed Adjuster Housing Disassembly

Disassemble high speed adjustors by removing poppet and spring. Remove circlip from housing and press adjustor out of housing. Pinch & remove and discard housing o-ring.

HS Housing Spring Removal

HS Housing Circlip Removal

HS Housing Circlip Removed

Removing Adjuster from Housing 1

Removing Adjuster from Housing 2

Removing O-Ring from Housing

Step 11 – Shuttle Disassembly

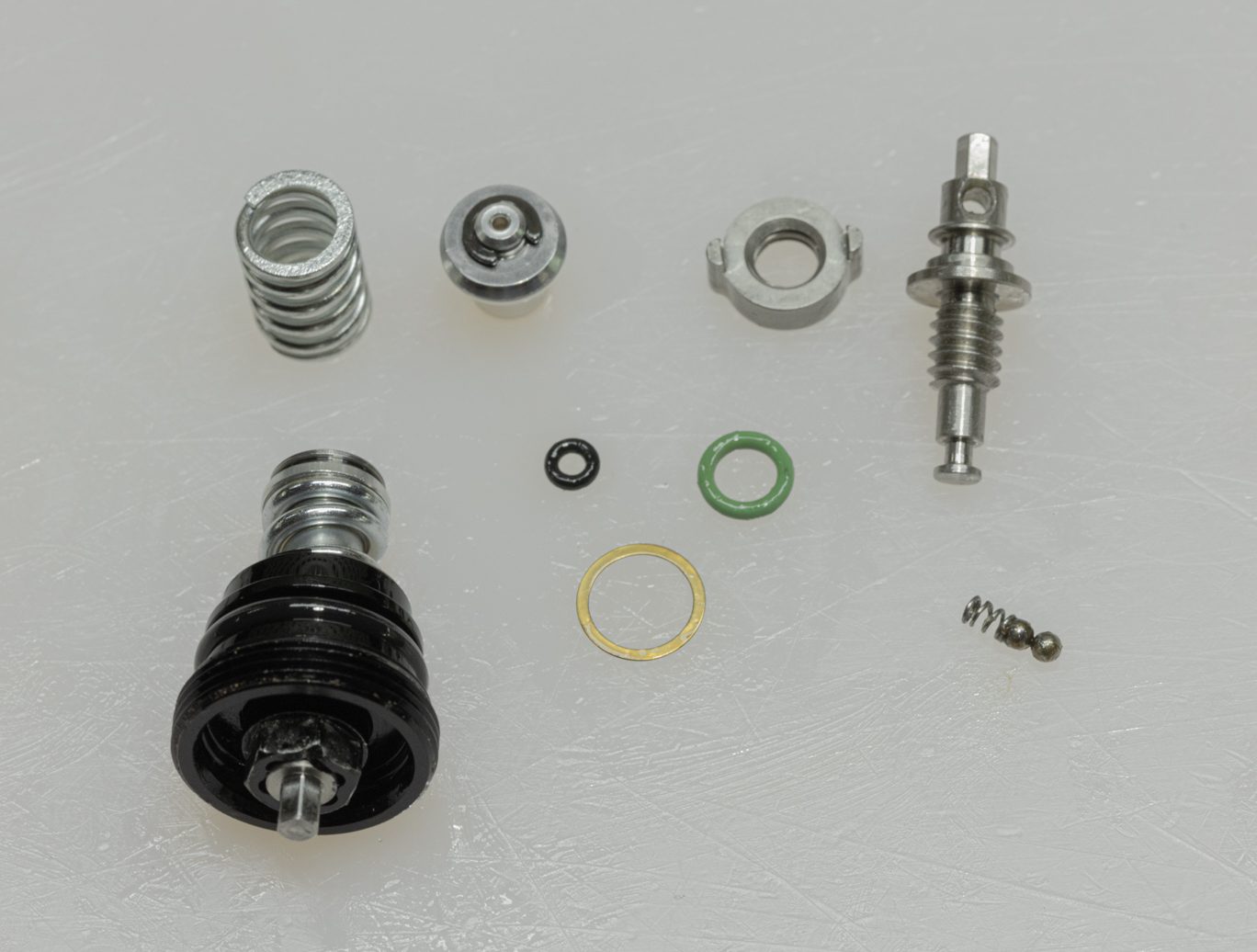

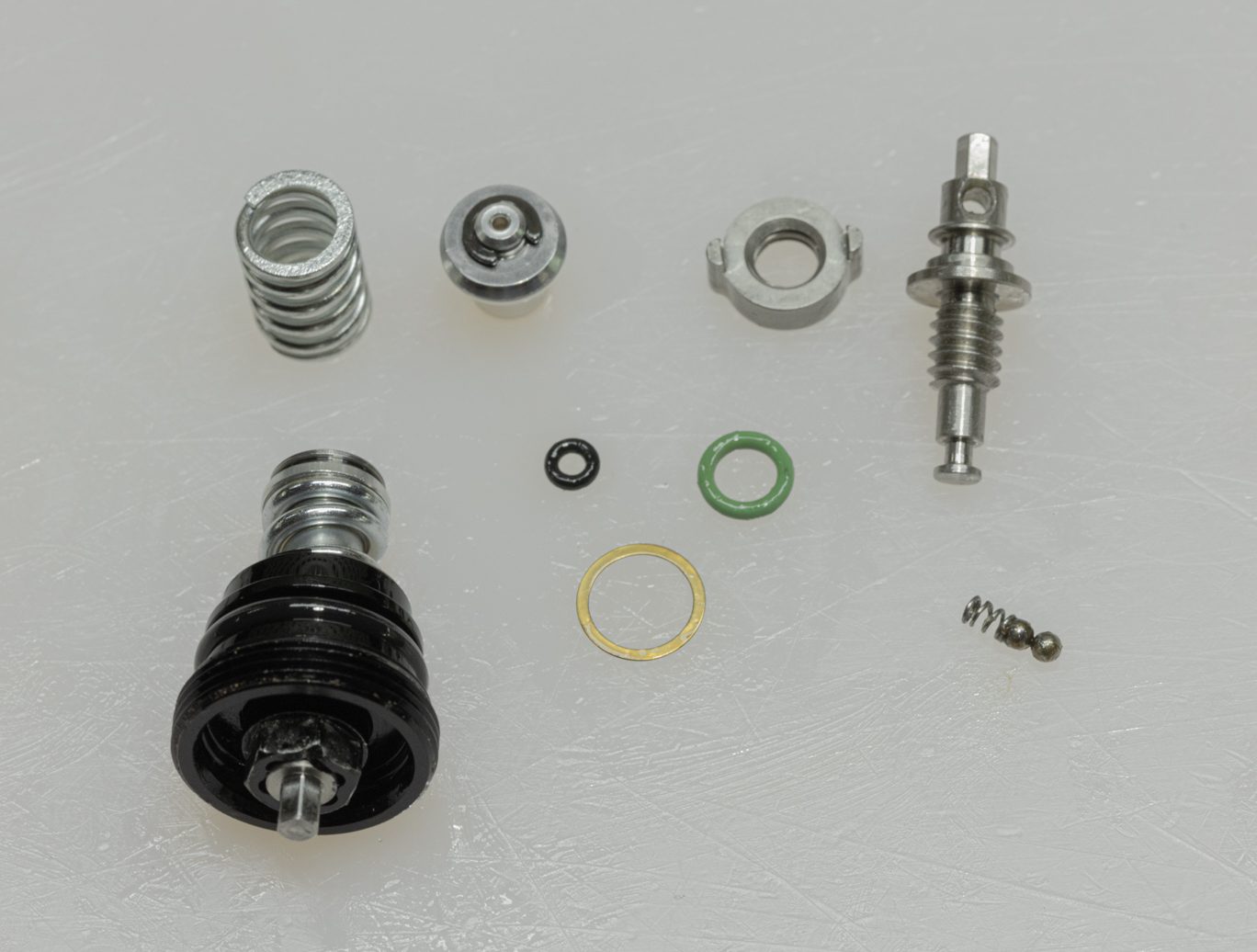

Press out detent spring and balls. Unthread shuttle, remove gold shim and remove both o-rings. Discard o-rings. Note the differences between the poppets and springs from the compression and rebound sides.

TSB038 – Kitsuma HSR Revalve

Detent Ball & Spring Removal

Unthreading Shuttle

Shuttle Shim Removal

Shuttle O-Ring Removal 1

Shuttle O-Ring Removal 2

Fully Disassembled Adjuster

Adjuster Poppet, Compression (L), Rebound (R)

Adjuster Spring, Compression (L), Rebound (R)

Continue to Part 2

Next