Air IL Complete 100 Hour Service Instructions (Part 4 of 4)

May 2023 orig., May 2024 rev.

Table of Contents

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek shocks have pressurized nitrogen and oil, even coil shocks. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service.

Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a shock still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

These service instructions cover the basic service procedures using standard service kits. If your suspension requires parts beyond standard replacement parts – shaft, damper tubes, end eyes – please consult your authorized Cane Creek service center or contact us at our Cane Creek Support Center.

Service Notes

The Air IL and Coil IL as well as the Standard and Trunnion and Previous Gen and Current Gen variants of both share many service steps. Some images in these instructions may not be identical to the valve body or outer damper tube to the shock being serviced, but that is only when the process is the same for the shock in the image and the shock on your bench. When steps vary, that will be noted and images included.

Service Kits

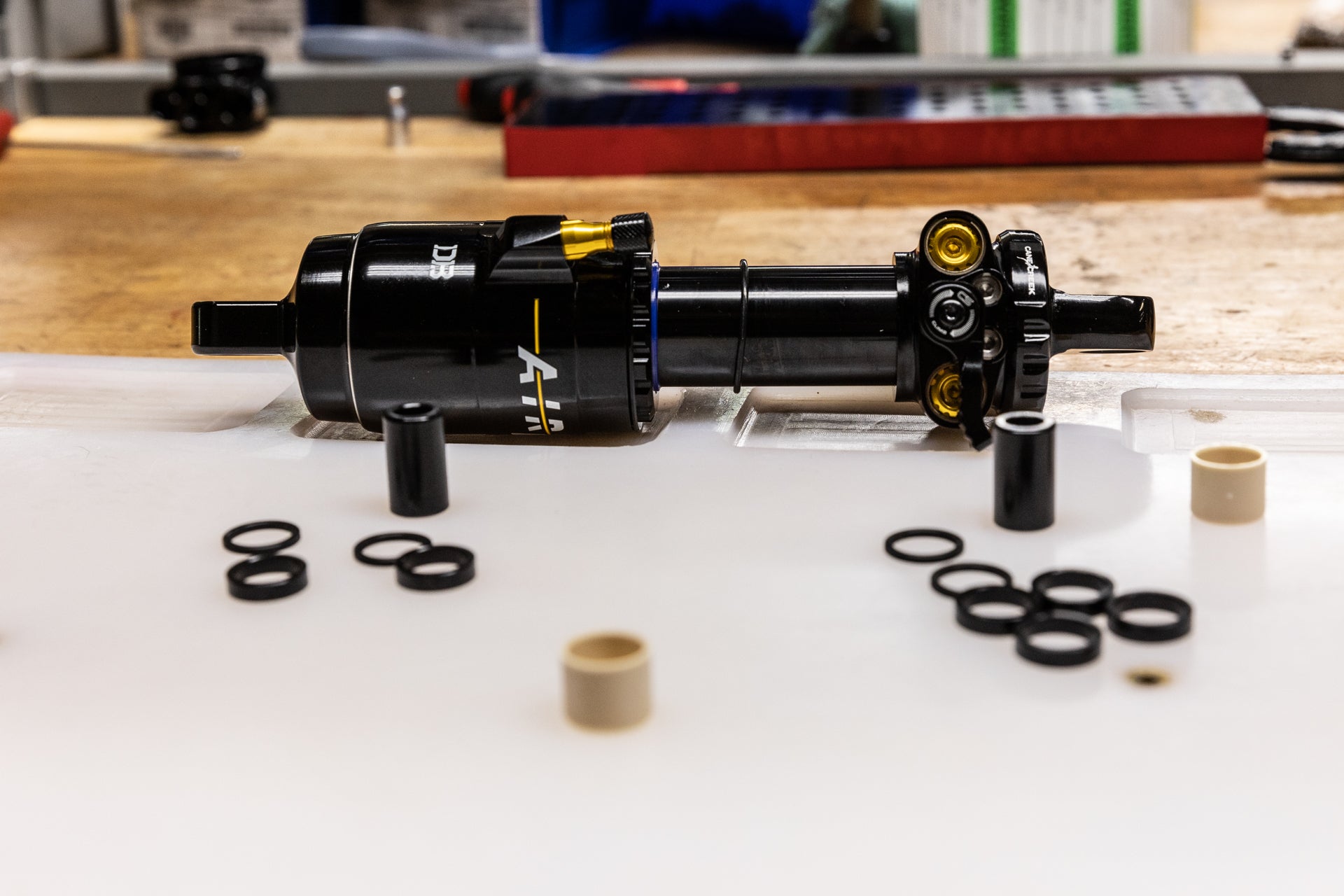

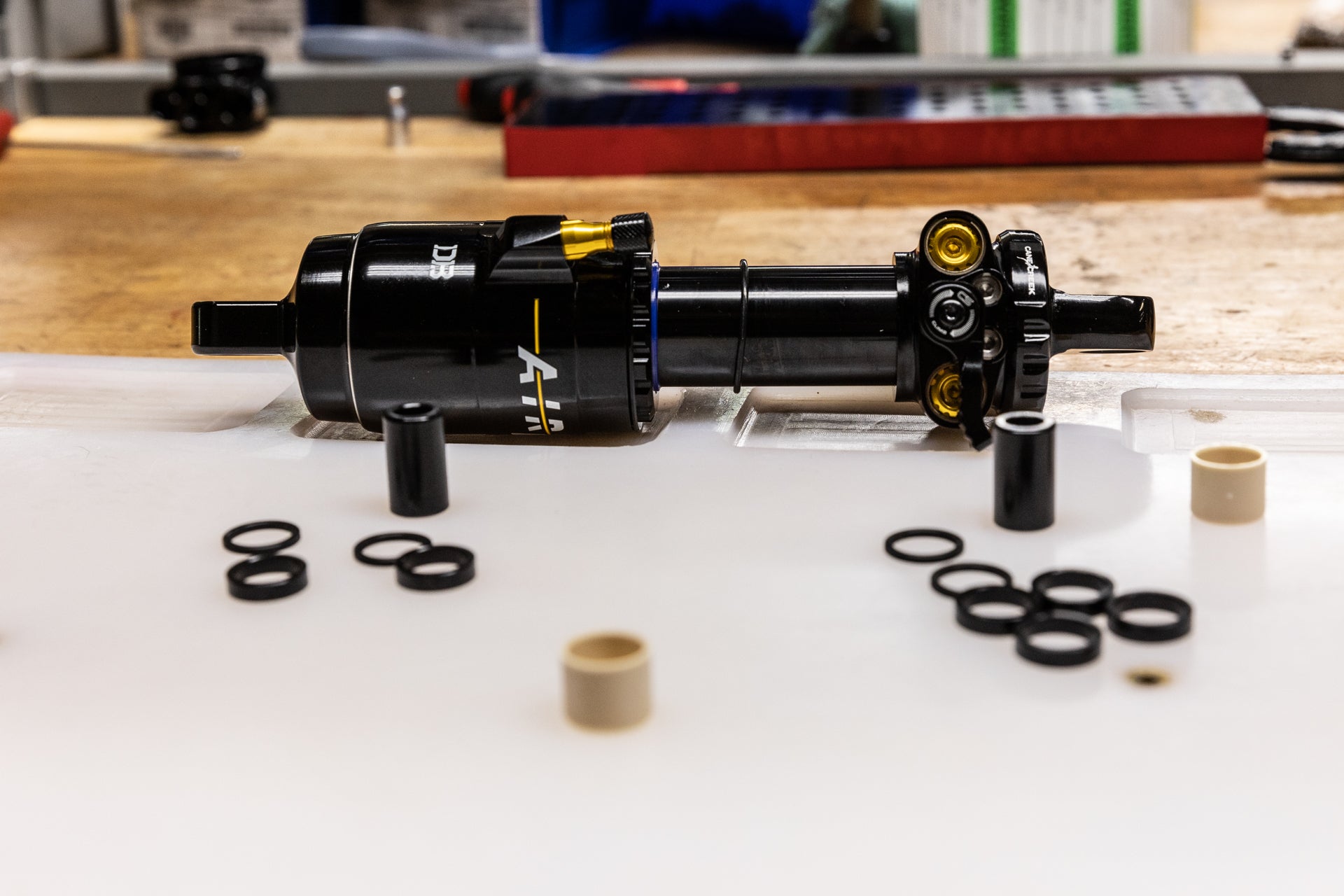

BAD1214-G2 or BAD1214T-G2 – Air IL G2 Damper Rebuild Kit (Standard or Trunnion)

BAD2279-G2 – Air IL G2 Air Spring Rebuild Kit

Required Cane Creek Tools

BCD0344 – Kitsuma/DBair/DBair IL Air Seal Head Tool

AAD1193 – Air Seal Head Bullet – Red

BAD1459 – Air Piston Funnel

BAD1032 – Gland Nut Wrench

BAD1174 – Oil Seal Head Pin Spanner Wrench

.DBT010 – DB 8mm Shaft Thread Cover (included in Rebuild Kit)

BAD2651 – IL G2 Fill Needle assembly

DBT016 – DB Gas Fill Needle

AAD0555 – 8mm & 9.5mm Shaft Clamp

AAD1454 – Kitsuma/IL Trunnion CS Bullet

BAD1273 – Inner Damper Tube Install Tool

AAD2650 – IL G2 Service Cradle (Standard Mount only)

Additional Tools & Supplies

Allen wrenches – 1.5, 3 & 4mm

Torx wrenches – T10, T15 & T25

1/2″ crowfoot wrench

Torque wrenches

Pick

Suspension Grease

Royal Purple 10w-30 Oil

Motorex 4wt Racing Fork Oil

Vacuum Oil Fill Machine

Nitrogen Fill System

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

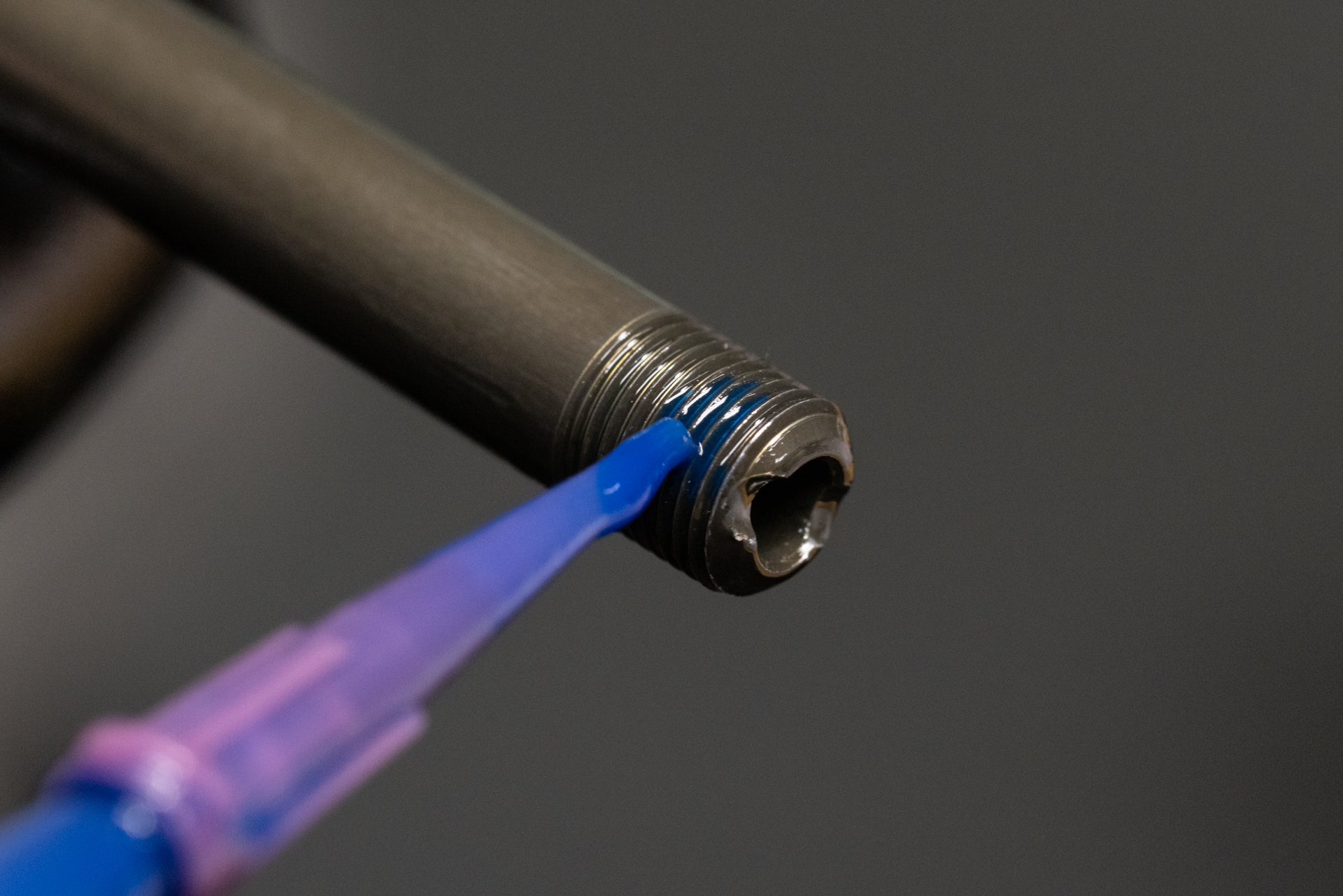

| Shaft Bolt | 5 Nm | 243 (Blue) |

| TSN | 0.6 Nm | 668 (Green) |

| Climb Switch Set Screws | 0.2 Nm | 243 (Blue) |

| Inner Damper Tube | 17 Nm | 263 (Red) |

| Oil Seal Head | 15 Nm | None |

| Gland Nut | 52 Nm | 243 (Blue) |

| Climb Switch Screw | 0.16 Nm | 243 (Blue) |

| Air Piston Screws | 3.2 Nm | 243 (Blue) |

| End Eye | 4.8 Nm | 243 (Blue) |

| Inner Air Can/Air Seal Head | 22.6 Nm | None (PolyLube) |

Oil Chart

| Oil Location | Oil Type | Oil Amount |

|---|---|---|

| Air Can | Royal Purple 10w-30 | 5 mL |

| Damper Fill | Motorex 4wt Racing Fork Oil | Fill to 3 Bars |

Nitrogen Chart

| Nitrogen Location | Nitrogen Pressure |

|---|---|

| Valve Body | 11 - 12 Bars |

Related Technical Service Bulletins

Review all related TSBs before performing any service.

No Air IL specific TSBs at this time.

Damper Fill

Step 1 – Prepping Shock for Fill

Install new o-ring (AAD0532) on fill plug screw. Temporarily install end eye on shaft. Secure shock in horizontal position with fill port facing up. Back all adjusters to fully open and open Climb Switch. Thread IL G2 oil fill adaptor (BAD2651) into fill port. Fully compress damper. Attach oil fill machine per your manufacturer’s instructions.

New O-Ring on Fill Screw

Trunnion Shock Set Horizontally

Standard Shock Set Horizontally

Fill Needle Attached

Attached to Fill Machine

Step 2 – Vacuum and Oil Fill Process

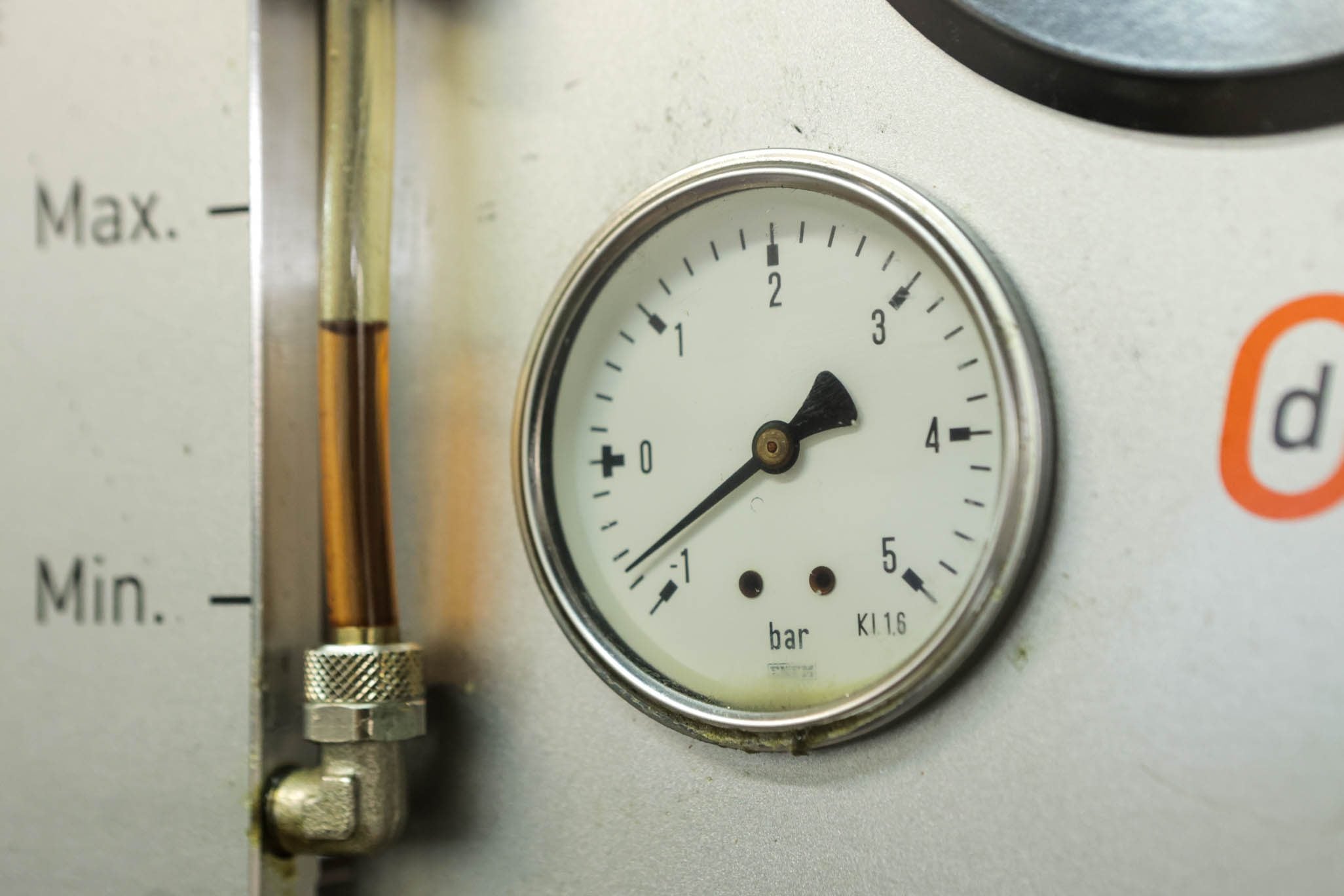

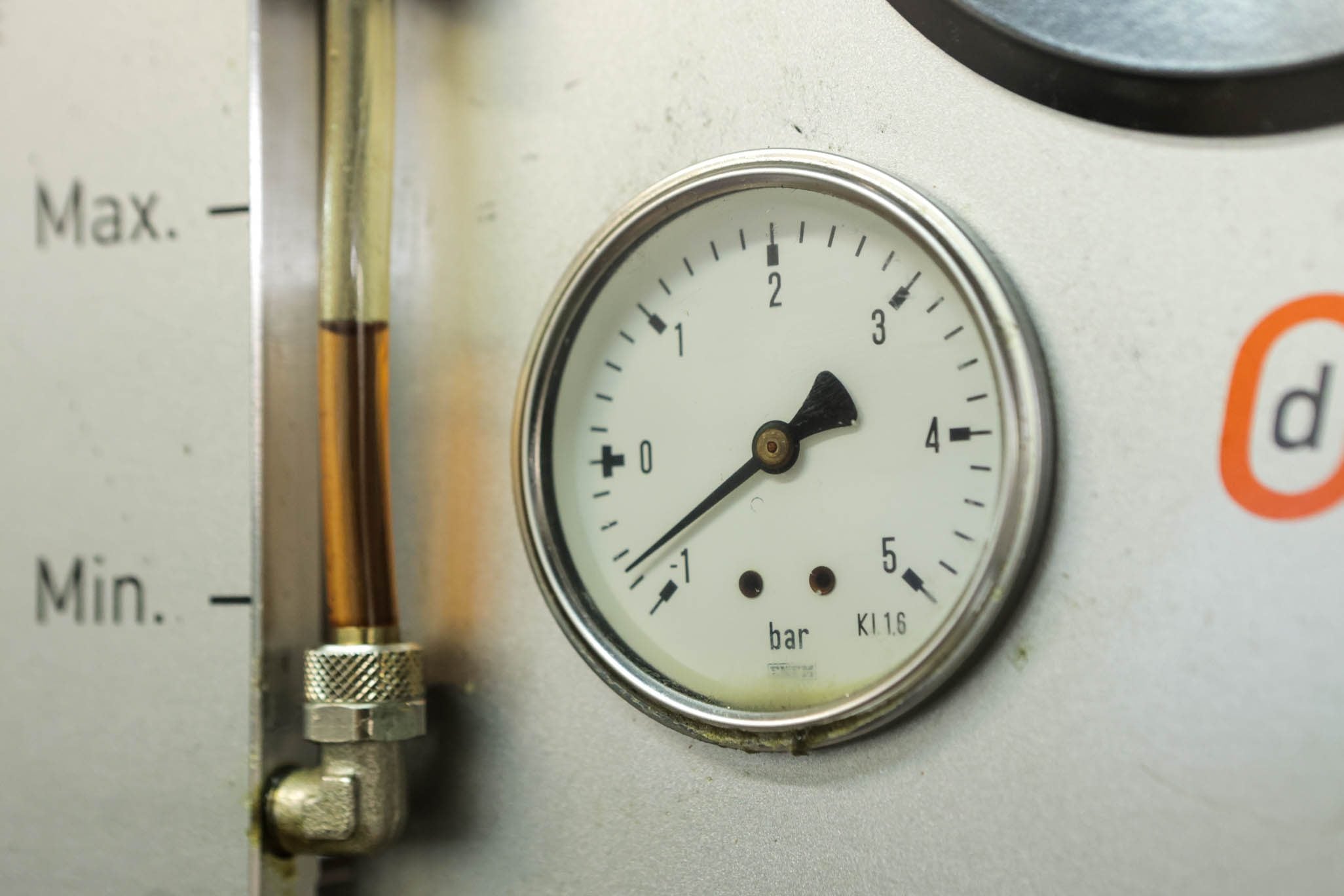

Vacuum system to (4) mbar. Pressure with Oil to (3) bar. Slowly cycle shaft finishing with shaft fully out. Cut fill and equalize pressure. Vacuum system to (4) mbar, leaving shaft out. Pressure again with Oil to (3) bar. Slowly cycle shaft finishing with shaft fully out. Cut fill.

Vacuum System to (4) mbar

Cycling Shock

Oil Pre-Fill

Oil Fill to (3) bar

Step 3 – Valve Body Closure

Leaving horizontal, disconnect fill machine. Unthread fill needle. Drip some oil on to top of fill. Install oil fill screw with T15.

Disconnecting Fill Machine

Installing Oil Fill Screw (Standard)

Installing Oil Fill Screw (Trunnion)

Oil Fill Screw Installed (Trunnion)

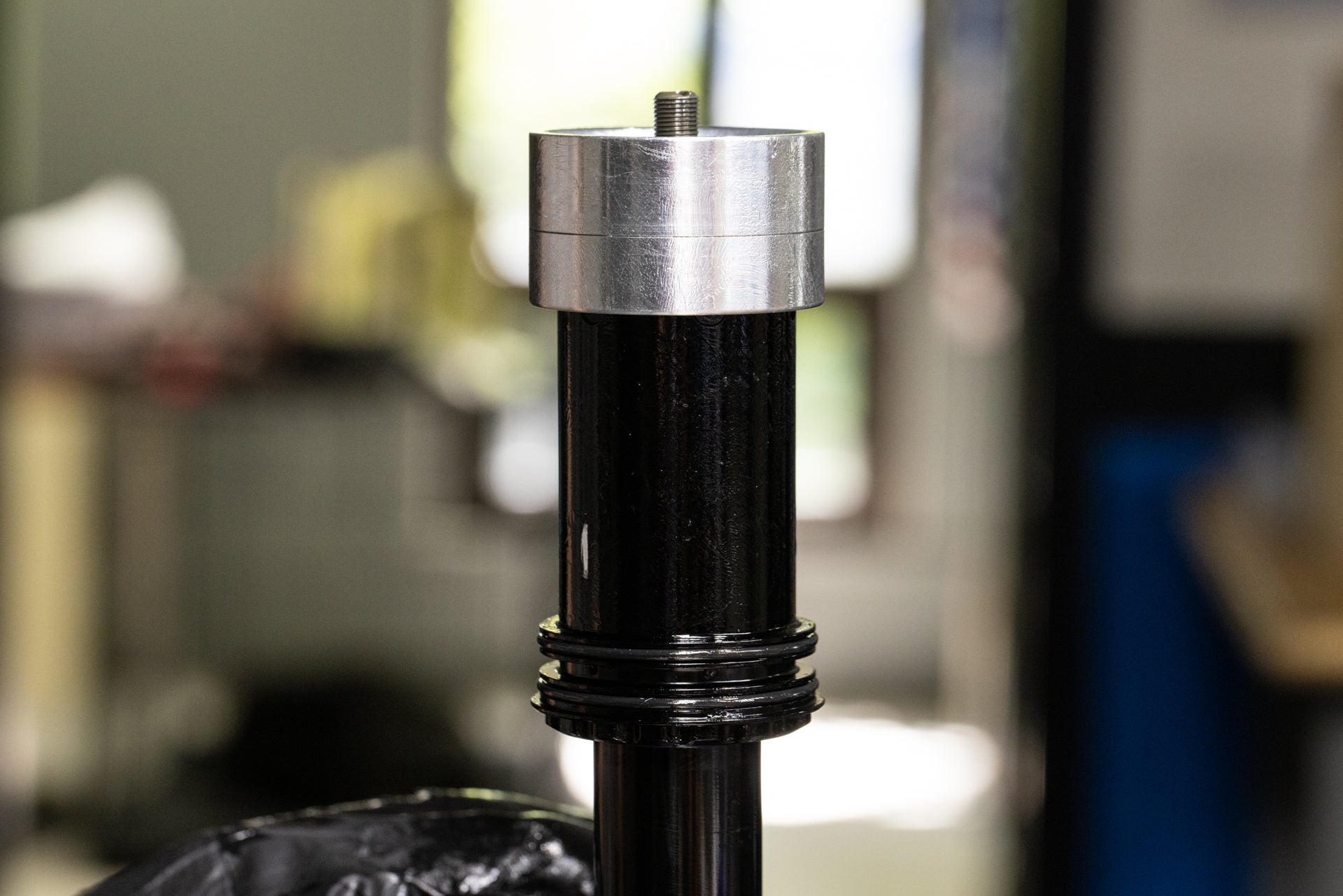

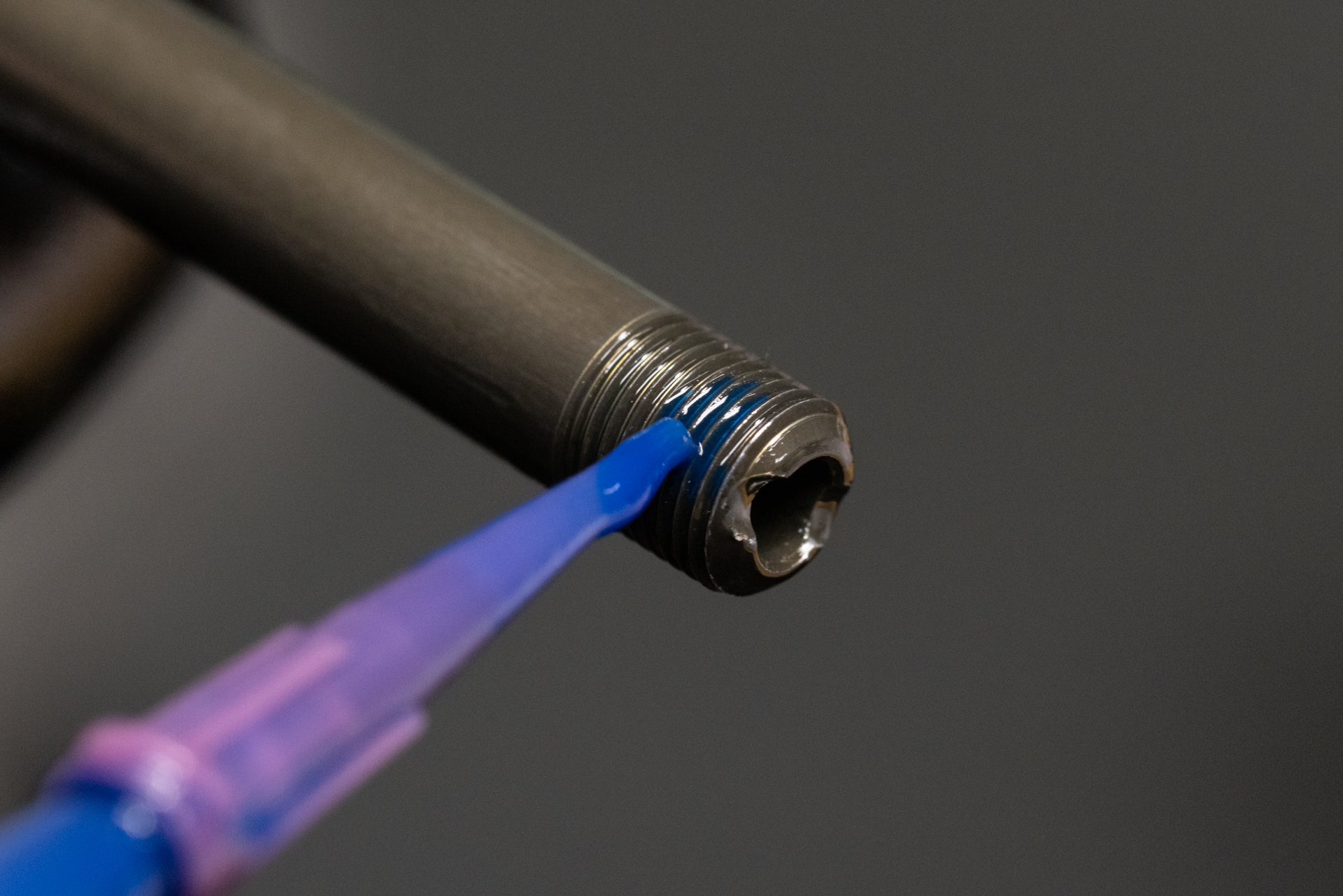

Step 4 – Nitrogen Fill

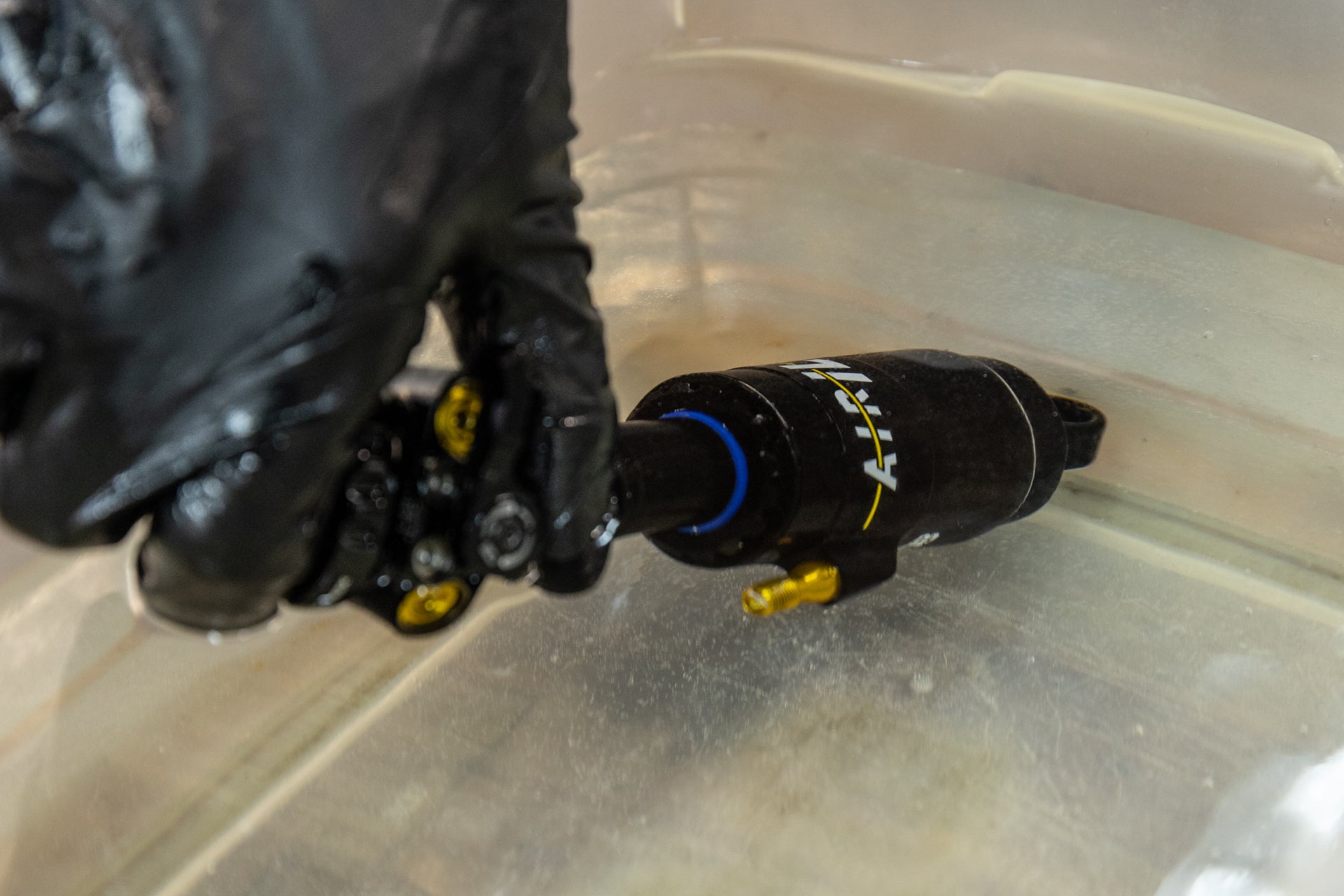

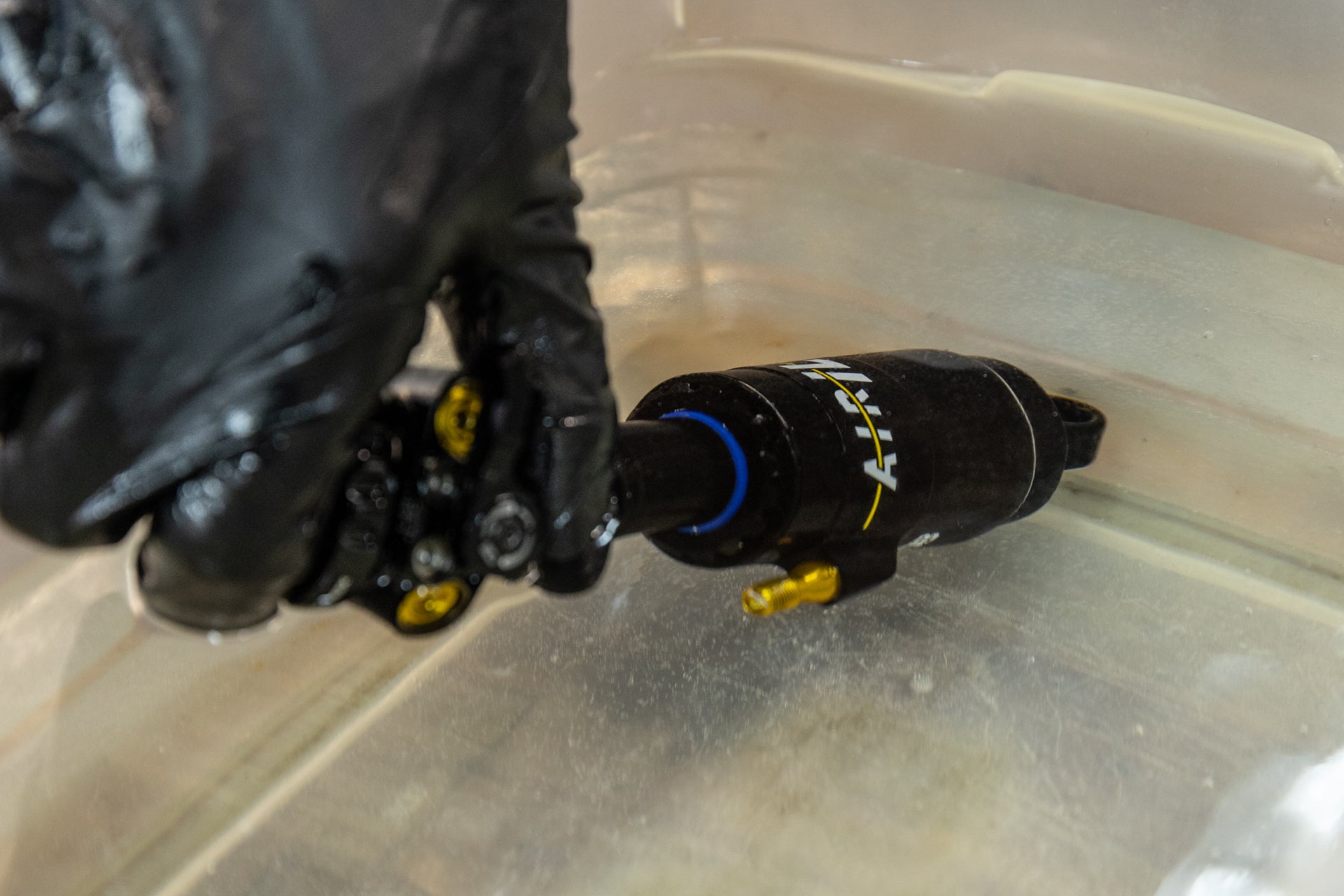

For Standard mount, Install gas fill plug (.DB11115) chamfer first. Thread fill screw in halfway. Trunnion, begin here. Insert gas fill needle (DBT016) and pressurize to 11-12 bars of nitrogen. Thread fill screw flush. Compress shaft and ensure proper gas by observing shaft return to full extension. Submerge valve body in water to check for gas leaks.

If mechanical dyno equipment is available, run shock on dyno at this point.

Install Gas Fill Plug (Standard only)

Install Gas Fill Plug Screw (Standard only)

Insert Nitrogen Fill Needle (Standard)

Insert Nitrogen Fill Needle (Trunnion)

Connect to Nitrogen Hose

Nitrogen Filled to Pressure

Threading Fill Screw Flush (Standard only)

Compression Test

Leak Test

Air Spring Reassembly

Step 1 – Air Piston Reassembly

Ensure inner and outer air cans, end eye, and piston are thoroughly cleaned. Grease piston quad ring channel. Thoroughly grease all sides of quad ring (ADD0125). Install quad ring on piston channel. Pre-compress back up L-rings (AAD2572) to improve fit on piston. Install back up L-rings on either side of quad ring, ensuring that flat side contacts quad ring.

Quad Ring Install on Air Piston

Air Piston L-Ring

Air Piston L-Ring Install

Air Piston Assembled

Step 2 – Inner Air Can Quad Ring Install

Grease lower channel on interior of inner air can. Install first L-ring (AAD1134) on lower shelf with flat side toward interior of channel. Thoroughly grease all sides of quad ring (AAD1846). Install quad ring into channel. Install second L-ring (AAD1134) on top of quad ring with flat side against quad ring.

Greasing Quad Ring Channel

First Air Can L-Ring Install

First Air Can L-Ring Installed

Greasing Quad Ring

Air Can Quad Ring Installed

Second Air Can L-Ring Install

Second Air Can L-Ring Installed

Step 3 – Inner Air Can Wiper & O-Ring Install

Install dry wiper seal (AAD0415) into top groove of inner air can. Thoroughly grease upper inner assembly of air can. Grease and install inner air can outer o-rings (AAD2142) on exterior of air can in the two grooves. Lightly grease the lower interior inner air can. Excess grease can clog charge port.

Air Can Wiper Install

Air Can Wiper Installed

Air Can O-Ring Install

Air Can O-Ring Installed

Inner Air Can Grease

Step 4 – End Eye & Outer Air Can Prep

Grease and install o-ring (AAD2142) into top groove on lower end eye. Insert stop shim (AAD1542) into end eye. Press into place below threads. Grease inner ridges of both ends on outer air can.

Air Can End Eye O-Ring Install

Air Can Stop Shim Install

Air Can Stop Shim Installed

Outer Air Can Grease 1

Outer Air Can Grease 2

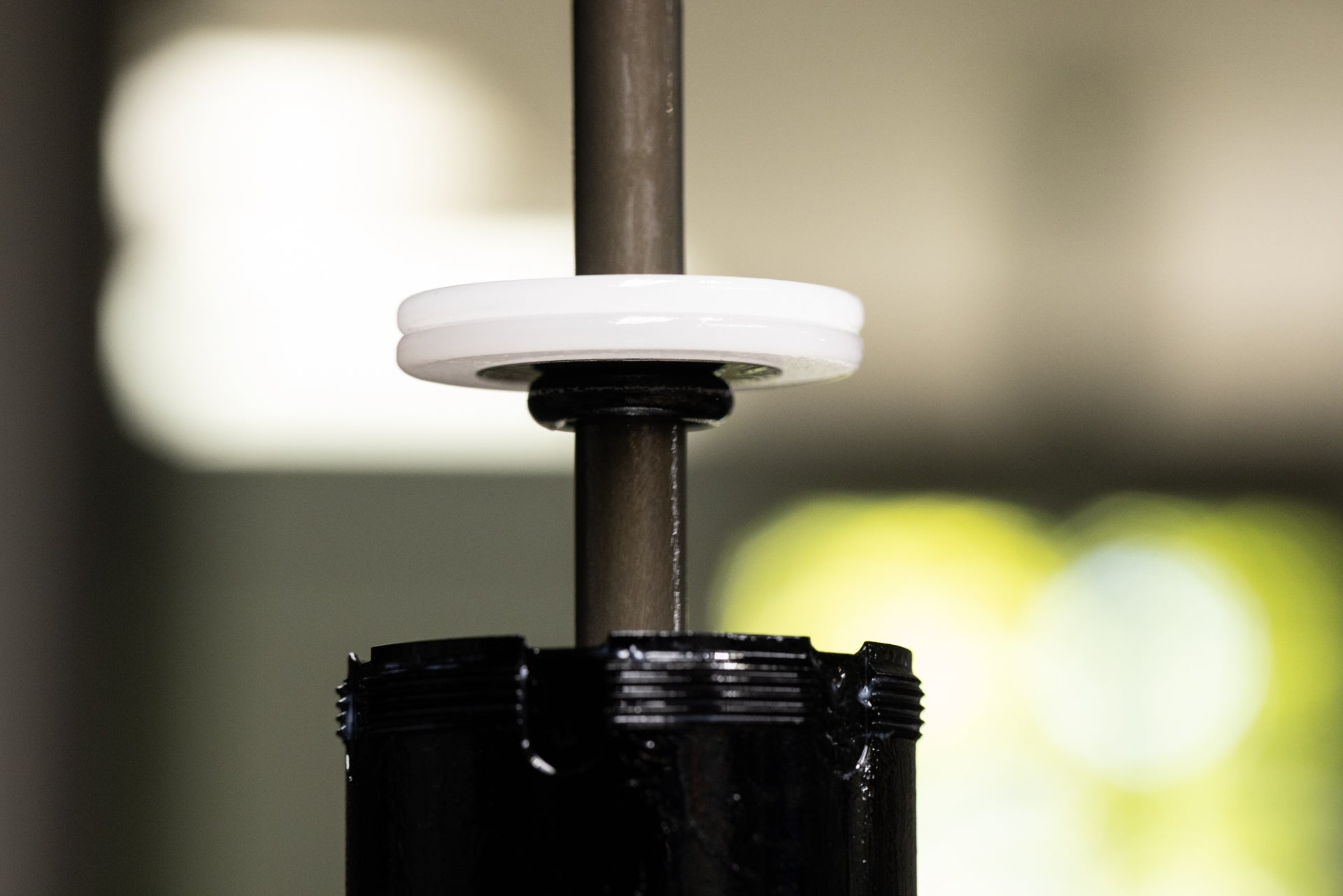

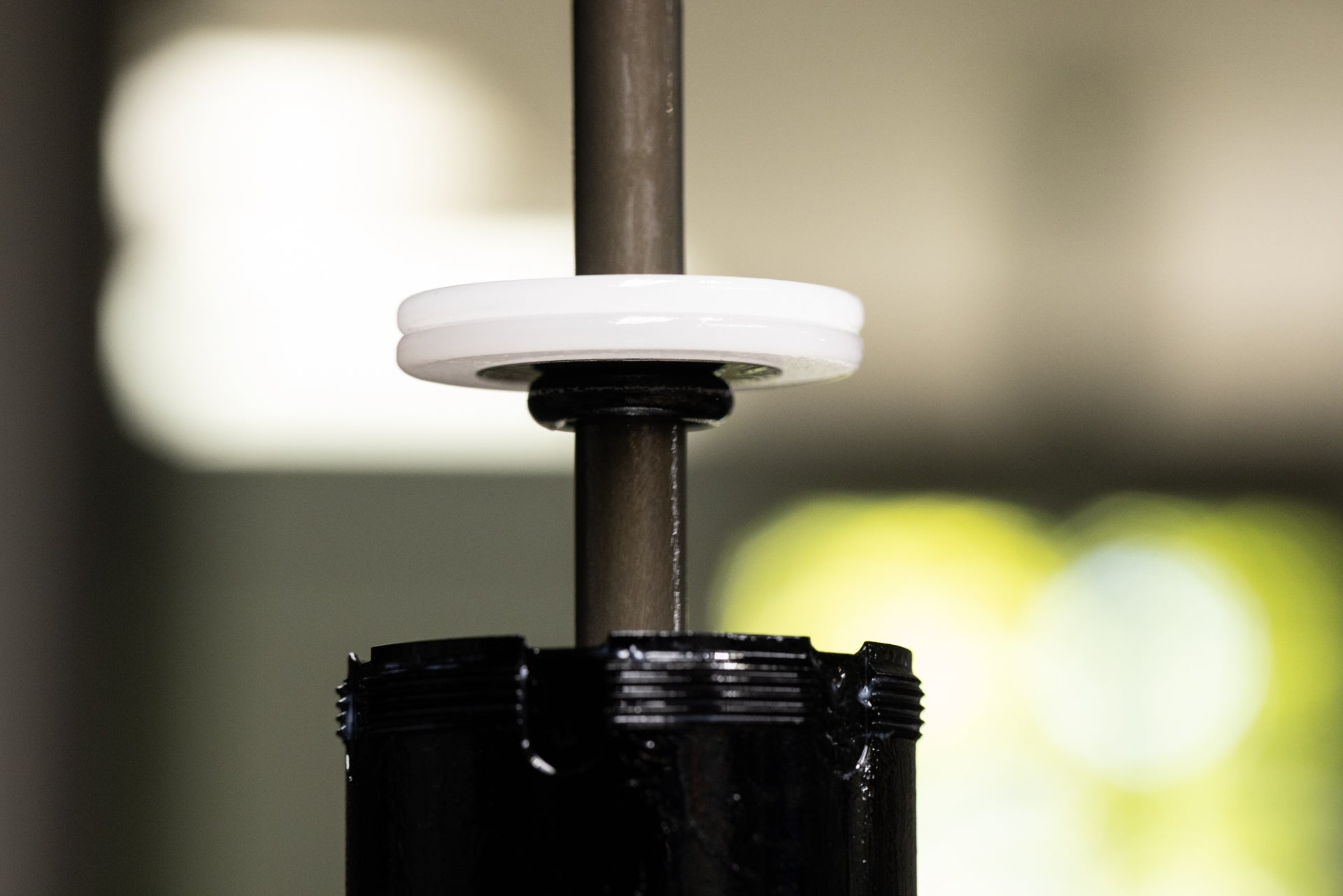

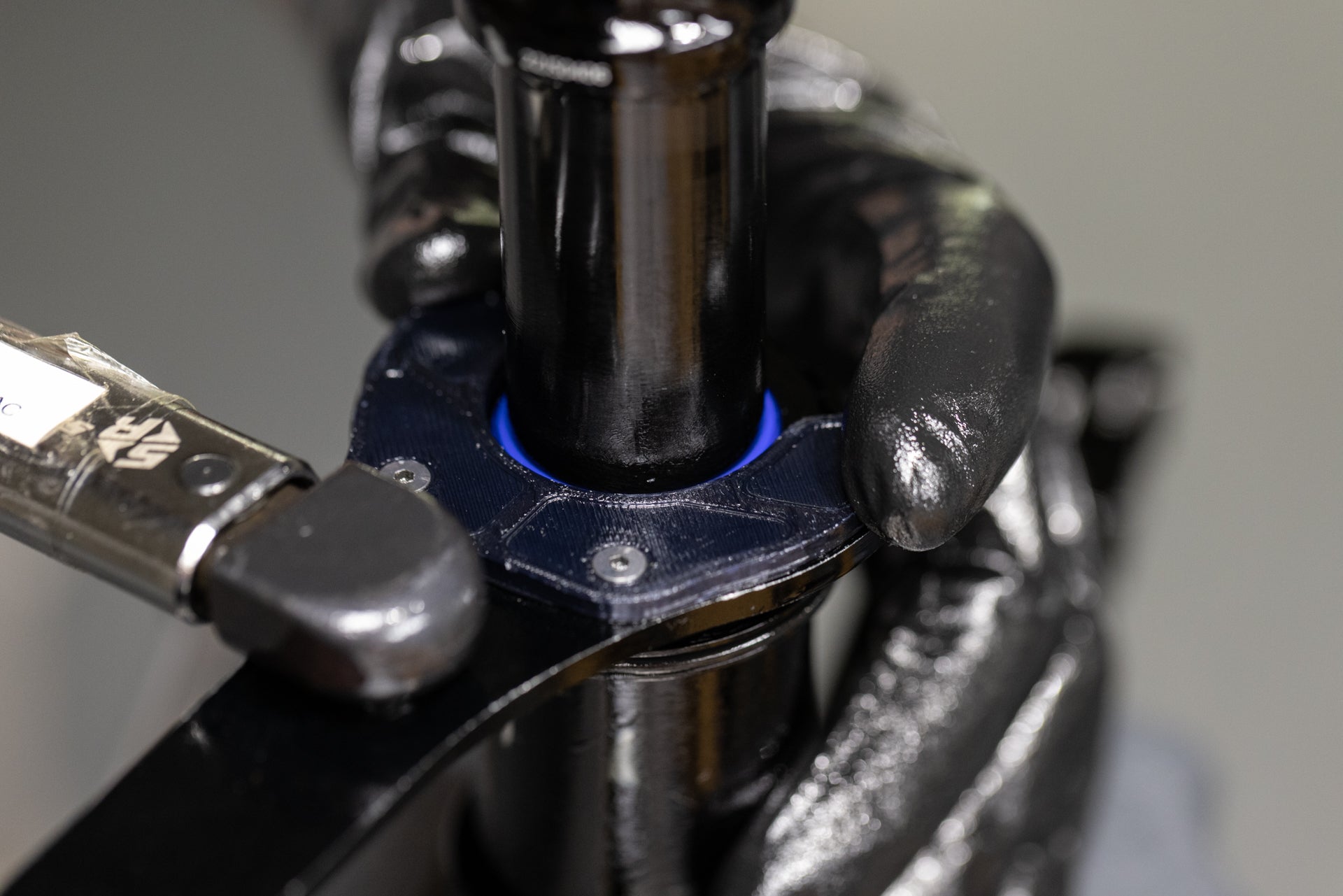

Step 5 – Inner Air Can Install

Clamp valve body in vise. Place Oil Seal Head Bullet (AAD1193) onto shaft. Install sag indicator o-ring (.DB11108). Install inner air can. Gently work the can past the bullet tool onto the body with a slight rotation and even pressure.

Sag O-Ring Install

Oil Seal Head Bullet on Shock

Inner Air Can Install

Inner Air Can Installed

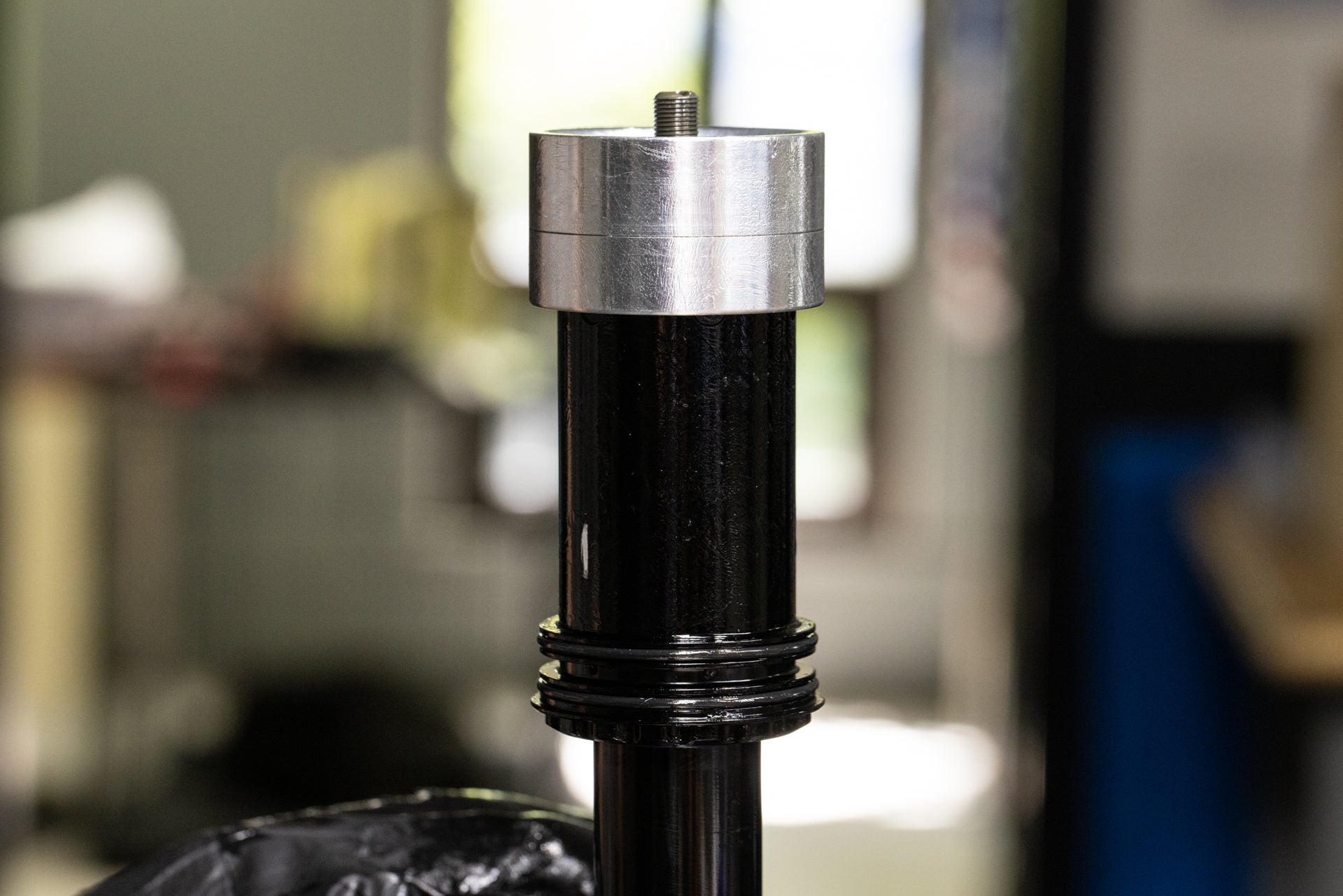

Step 6 – Air Piston Install

Thoroughly grease air piston o-ring (AAD2573) and place on oil seal head grove. Thoroughly grease the exterior of air piston. Apply blue Loctite (243) to three air piston set screws. Place IL G2 Air Piston Funnel (ADD0313) on inner air can. Set inner air can halfway on outer damper tube to allow for space to install air piston. Install piston with set screw holes facing out. Gently work piston past funnel into inner air can. Bottom piston onto seal head. Once flush with seal head, rotate inner can and piston to align screw holes with seal head threads. Install piston set screws. Torque to 3.2 Nm with T10.

Air Piston O-Ring Install

Air Piston O-Ring Installed

Greasing Air Piston

Prepping Piston Set Screws

Air Piston Funnel on Inner Air Can

Air Piston Installed Through Funnel

Aligning Air Piston w/ Seal Head

Piston Set Screws Install

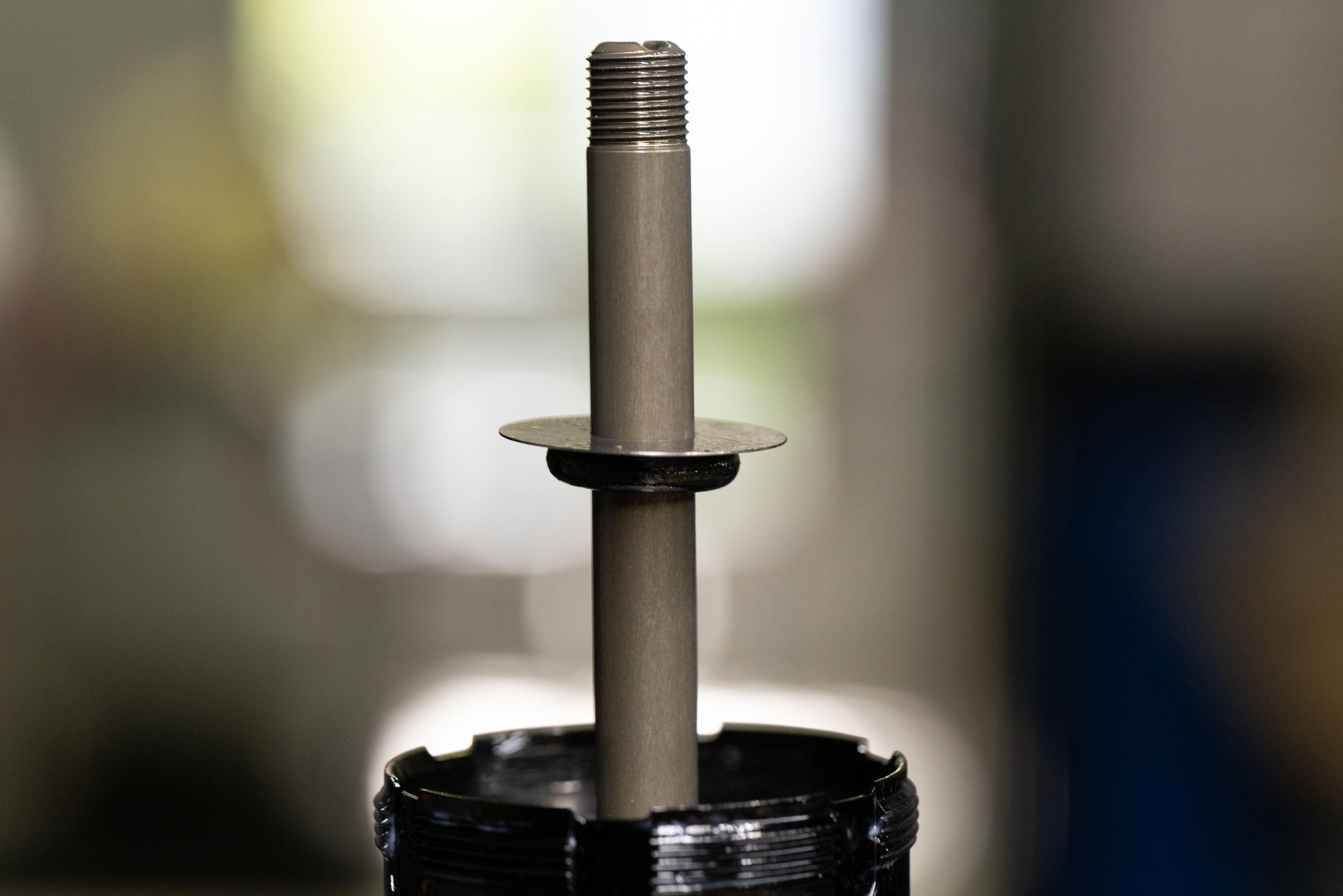

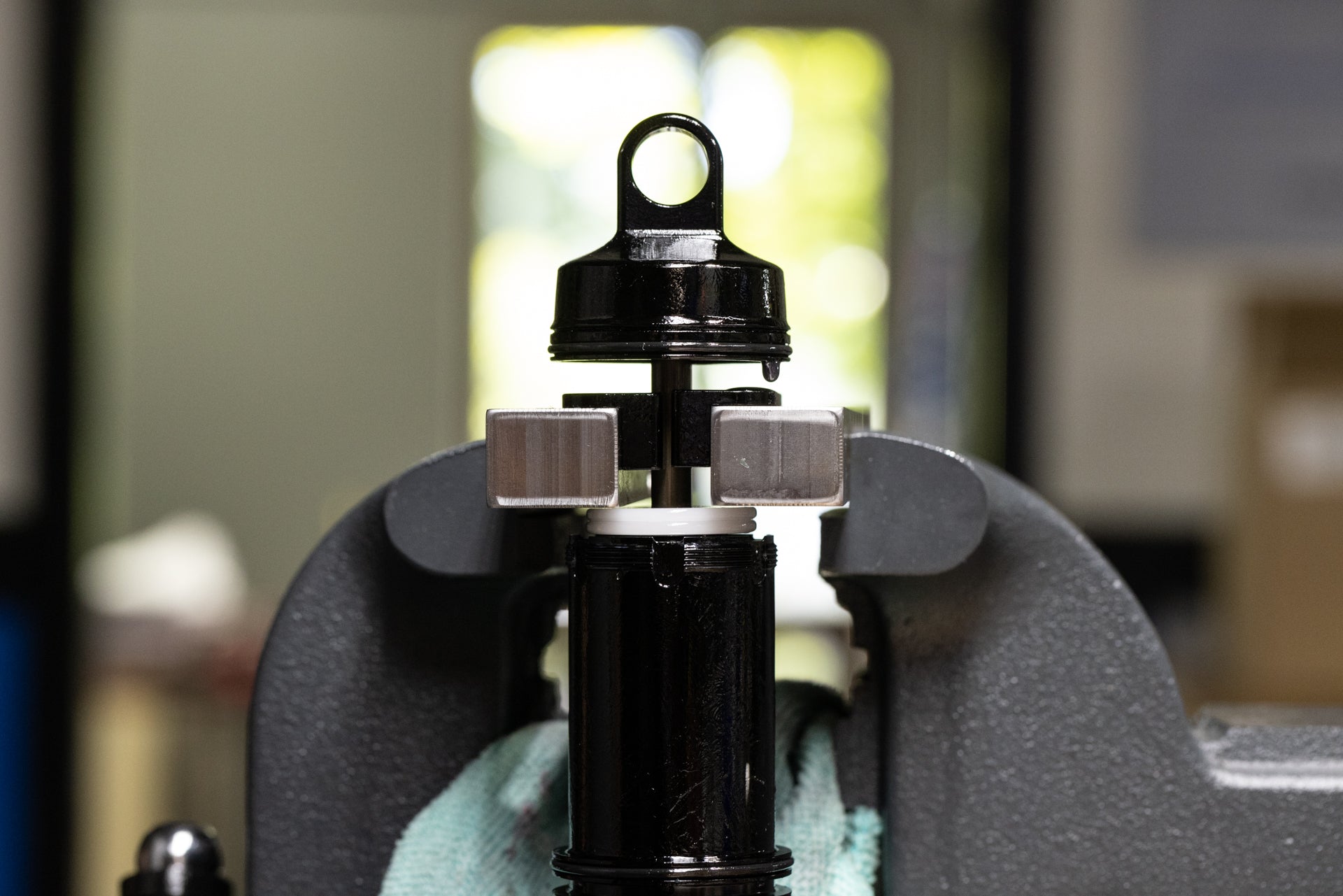

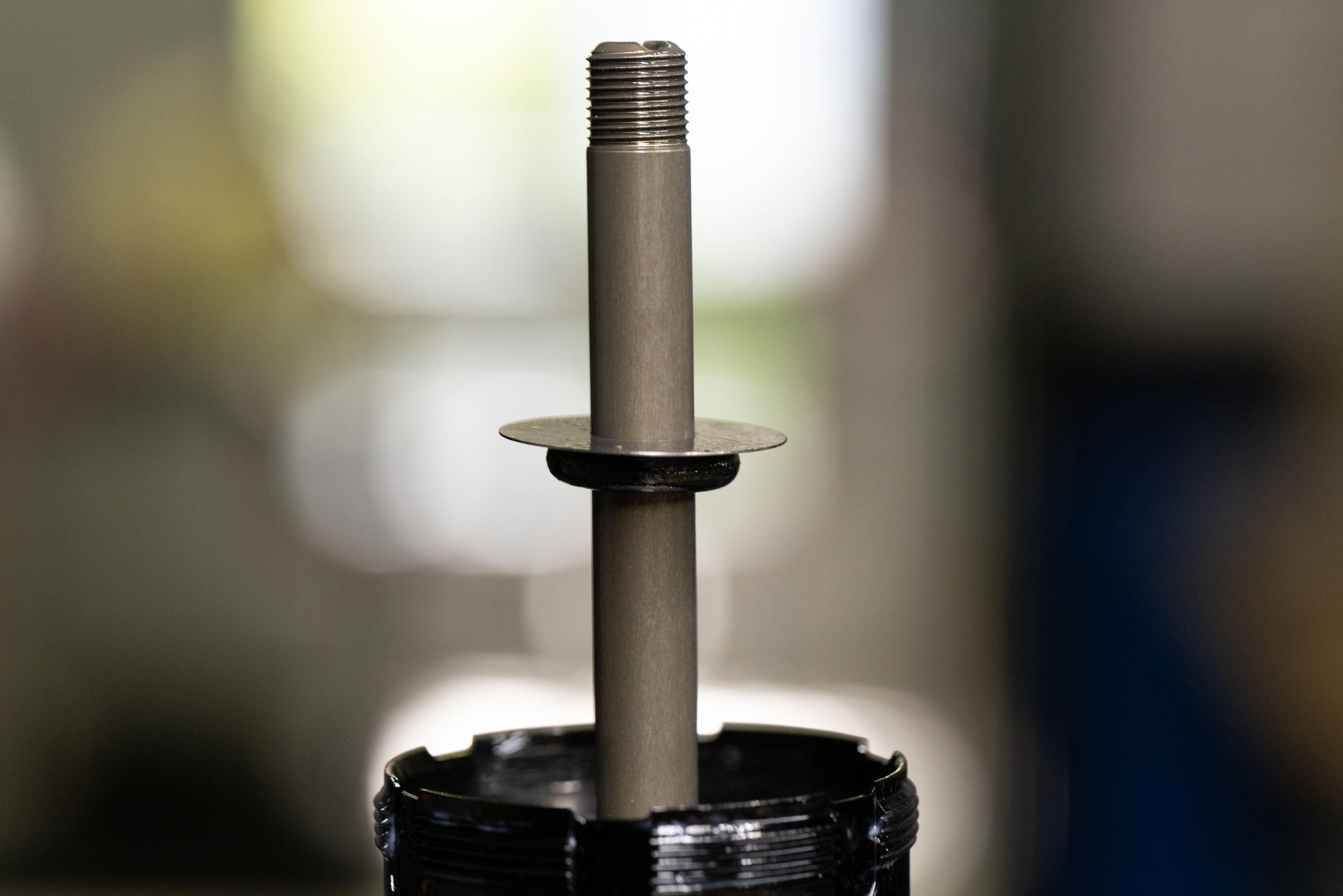

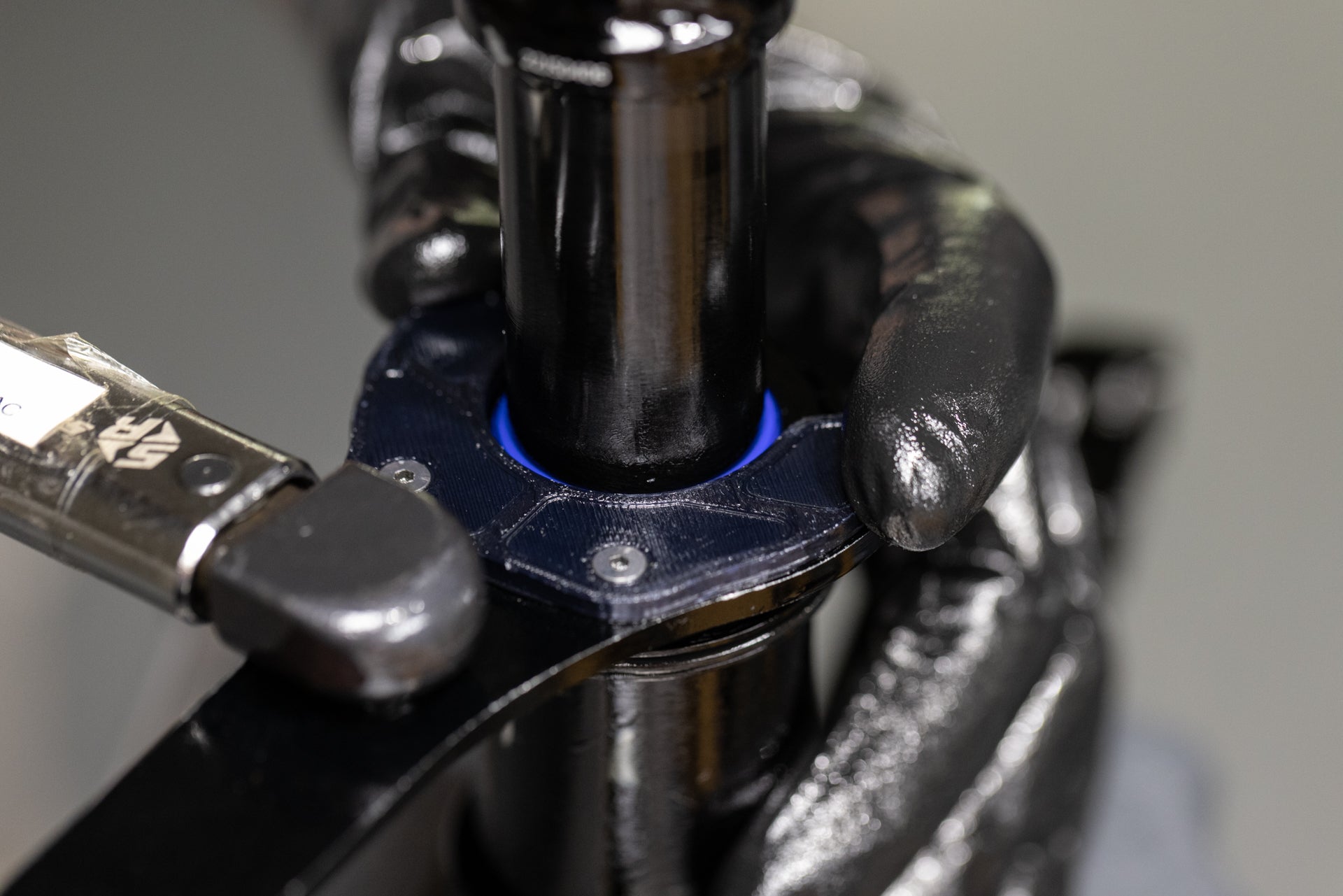

Step 7 – End Eye Install

Reinstall bottom out bumper, shim and stroke reduction (if present). Apply blue Loctite (243) to shaft threads and end eye threads. Thread end eye onto the shaft. Clamp shaft into vise with shaft clamp allowing space for end eye to clear vise when tightened. Using 1/2″ crowsfoot, torque end eye to 4.8 Nm. Clean any extra Loctite from shaft and end eye.

Bottom Out Bumper Installed

Shim Installed

Stroke Reduction Installed

Applying Loctite to Shaft

Applying Loctite to End Eye

Threading Shaft to End Eye

Clamping Shaft w/ Ample Space

Torquing End Eye

Cleaning Shaft & End Eye of Loctite

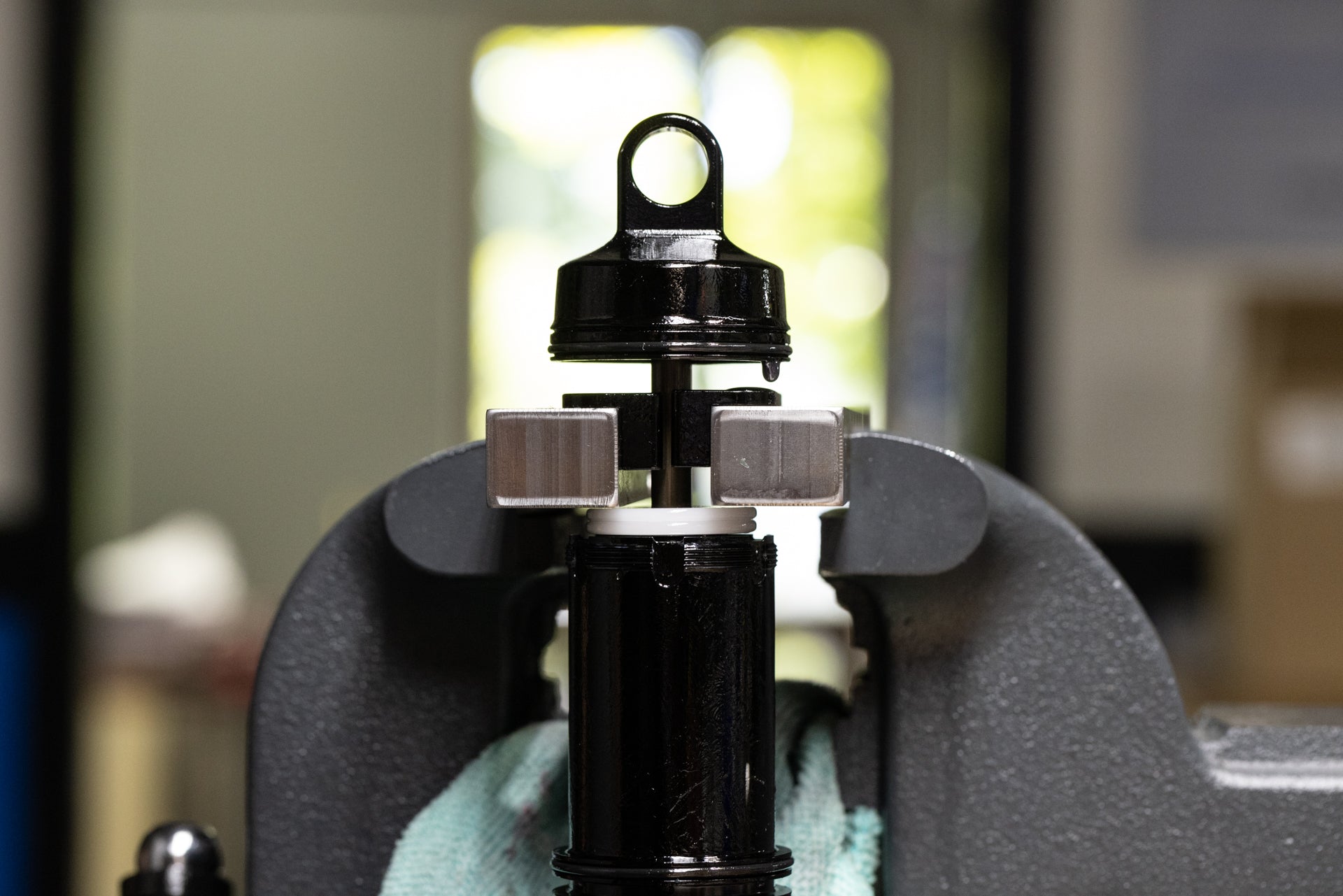

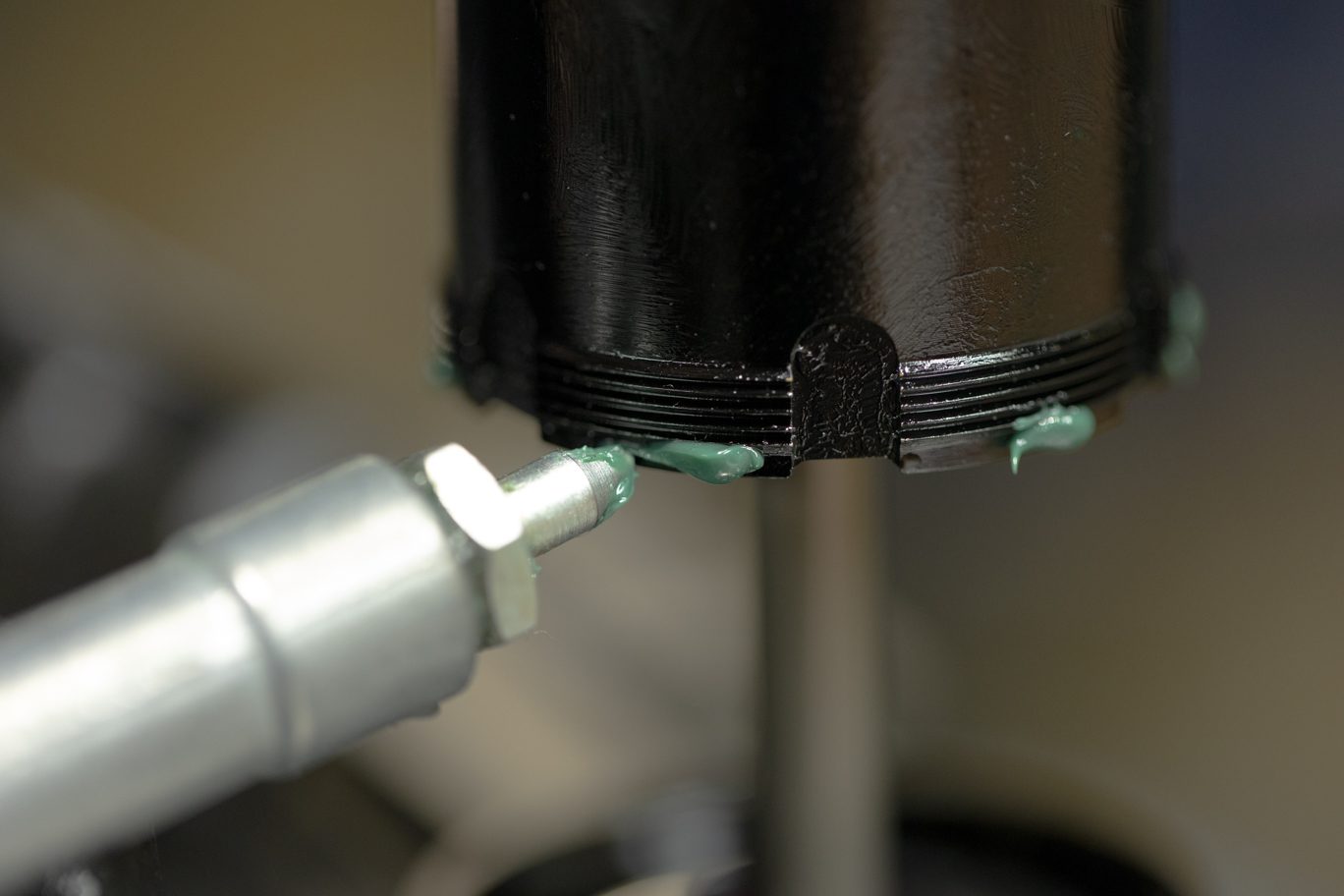

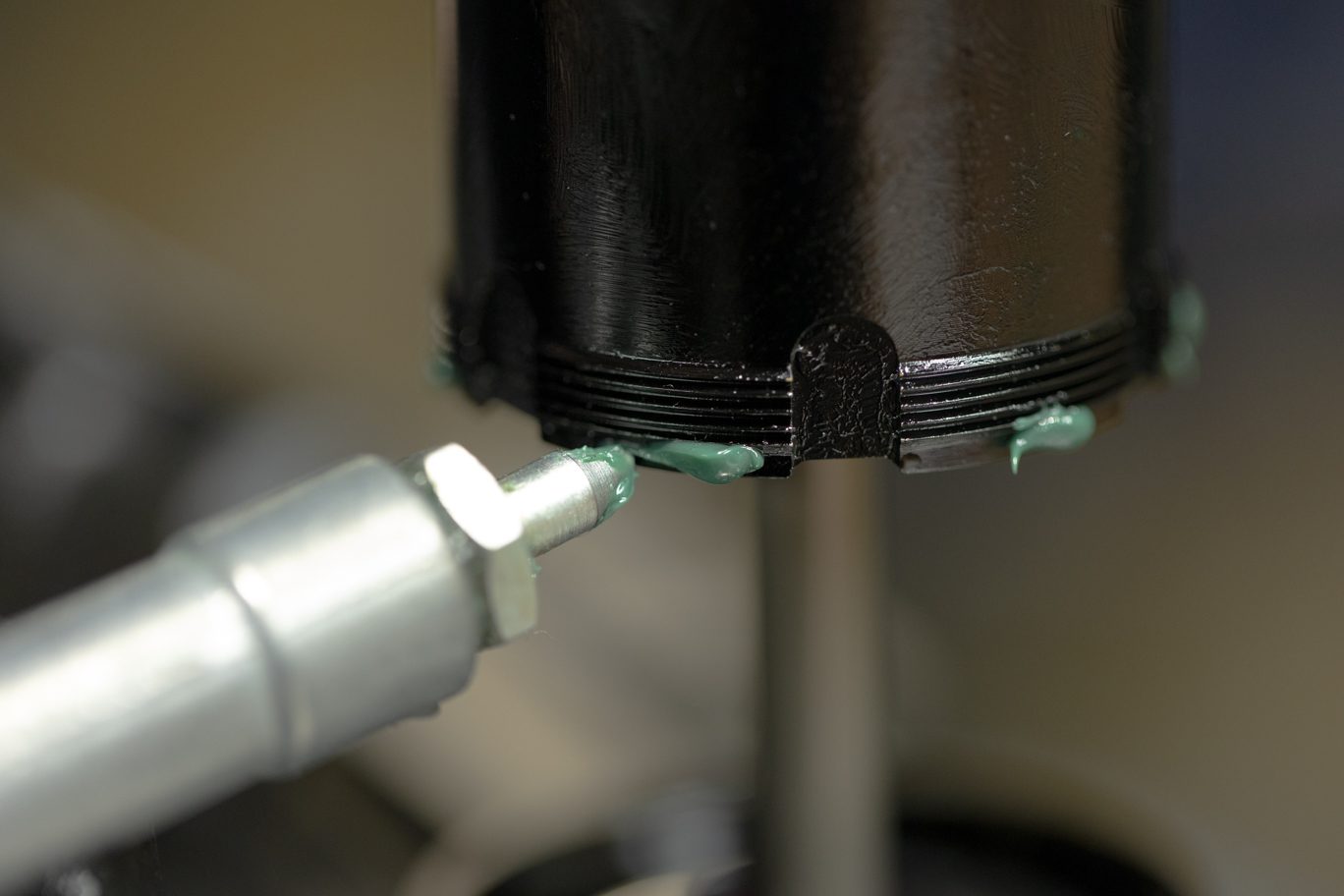

Step 8 – Inner Air Can to End Eye Install

Clamp end eye in vise. Add 5 ml of Royal Purple to end eye. Add PolyLube grease to threads on inner air can. Thread inner air can onto end eye. Torque to 22.6 Nm using Air Seal Head tool.

Clamped for Inner Air Can to End Eye Install

Adding Oil to End Eye

Adding PolyLube to Inner Air Can

Lowering Inner Air Can onto End Eye

Threading Inner Air Can onto End Eye

Air Seal Head Tool

Air Seal Head Tool on Inner Air Can

Step 9 – Outer Air Can Install

Clamp valve body end into vise. Work outer air can gently past o-rings. Note correct orientation of air can and reinstall any volume reduction. Final o-ring will be tight. Strap wrench may be necessary. Engage Climb Switch to aid installation. Ensure valve is oriented away from Climb Switch. Install outer air can retention clip.

Shock Clamped (Trunnion)

Outer Air Can Installation 1

Outer Air Can Installation 2

Outer Air Can Installed

Outer Air Can Retention Ring Install

Outer Air Can Retention Ring Installed

Final Testing and Set Up

Step 1 – Leak Check

Air up shock to at least 100 psi. On hand dyno or bike frame, slowly cycle shock and listen for negative volume chamber to pressurize. Using soapy water and dunk tank, test for any possible air leaks. Install valve cap.

Airing Up Shock

Shock on Hand Dyno

Soap Test 1

Soap Test 2

Soap Test 3

Soap Test 4

Dunk Test

High Speed Adjust

Step 2 – Dyno Test

Set adjusters to factory neutral: HSC & HSR 2.5 turns from full bottom (or 2 turns from full open); LSC 11 clicks from full bottom; LSR 13 from full bottom. Using hand dyno, test shock for function. Ensure Climb Switch engages and operates properly. Turn individual adjusters to test each one. Set back to original tune if desired.

Install any bushings and hardware.

High Speed Adjust

Low Speed Adjust