Tigon Stroke Change

Feb 2024 orig.

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek shocks have pressurized nitrogen and oil, even coil shocks. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service.

Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a shock still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

Service Notes

This service covers changing stroke ONLY on a new Tigon shock. As o-rings are considered new as part of this service, they will not be replaced. If this stroke change is being done on an older shock, a full 100 hour service is recommended.

The stroke change procedure is the same for Standard and Trunnion mount shocks. Only where to clamp the valve body varies.

Service Kits

No service kits required. If decreasing stroke, one of the below Stroke Reducers will be required:

ADD0233 – Tigon – 2.5mm Stroke Reducer

ADD0234 – Tigon – 5mm Stroke Reducer

Required Cane Creek Tools

None

Additional Tools & Supplies

Crowfoot wrench – 34mm

Torque wrench

Pick – metal & plastic

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

| RAMP Tube | 14.5 Nm | None |

General Prep

Clean shock. Remove hardware if needed to clear preload collar. Remove preload collar circlip. Remove preload collar and spring.

Shock Ready for Stroke Change

Preload Collar Circlip Removal

Preload Collar Circlip Removed

Preload Collar Removal

Spring Removal

Ready for Stroke Change

RAMP Tube & Stroke Reduction Removal

Step 1 – Air Removal

Remove valve cap and release any air from RAMP tube. Remove spring spacer.

Valve Cap Removal

Air Removal from RAMP Tube

Spring Spacer Removal

Step 2 – RAMP Tube Opening

Clamp valve body in soft jaw vise. Loosen RAMP tube using 34mm crowsfoot. Use caution as contents of shock can still have pressurized air. Hold outer damper tube and unthread RAMP tube. Take care to not slide RAMP tube past the oil seal head on the damper tube.

Shock Clamped for RAMP Tube Removal

Freeing RAMP Tube

RAMP Tube Unthreaded but not Removed

RAMP Tube Pushed up to Oil Seal Head

Step 3 – Removing Stroke Reduction

Slide top out bumper and washer out of the valve body. Remove stroke reduction if present and pull off shaft.

Stroke Reduction Removed from Valve Body

RAMP Tube Reassembly

Step 1 – Stroke Reduction Install

If RAMP tube was completely removed, lightly grease inner rim of RAMP tube and outer edge of oil seal head. Install RAMP tube on damper tube, using a pick to work RAMP tube past oil seal head. Install stroke reduction if needed. Be sure to seat fin on reduction in valve body properly.

Greasing RAMP Tube

Greasing Oil Seal Head

RAMP Tube Install

Working Oil Seal Head Past RAMP Tube Lip 1

Working Oil Seal Head Past RAMP Tube Lip 2

RAMP Tube Past Oil Seal Head

Stroke Reduction Install

Stroke Reduction Installed on Shaft

Stroke Reduction Installed in Valve Body

Step 3 – RAMP Tube Install

Thread RAMP tube onto valve body. Clamp valve body in soft jaw vise. Using 34mm crowsfoot, tighten RAMP tube onto valve body to 14.5 Nm.

Seating RAMP Tube on Valve Body

RAMP Tube Seated on Valve Body

Valve Body Clamped for RAMP Tube Install

Threading RAMP Tube on Valve Body

Torquing RAMP Tube on Valve Body

Final Prep

Spring Reinstall

Set adjusters to factory neutral. Using hand dyno, test shock for function. Ensure Climb Switch engages and operates properly. Turn individual adjusters to test each one. Set back to original tune if desired.

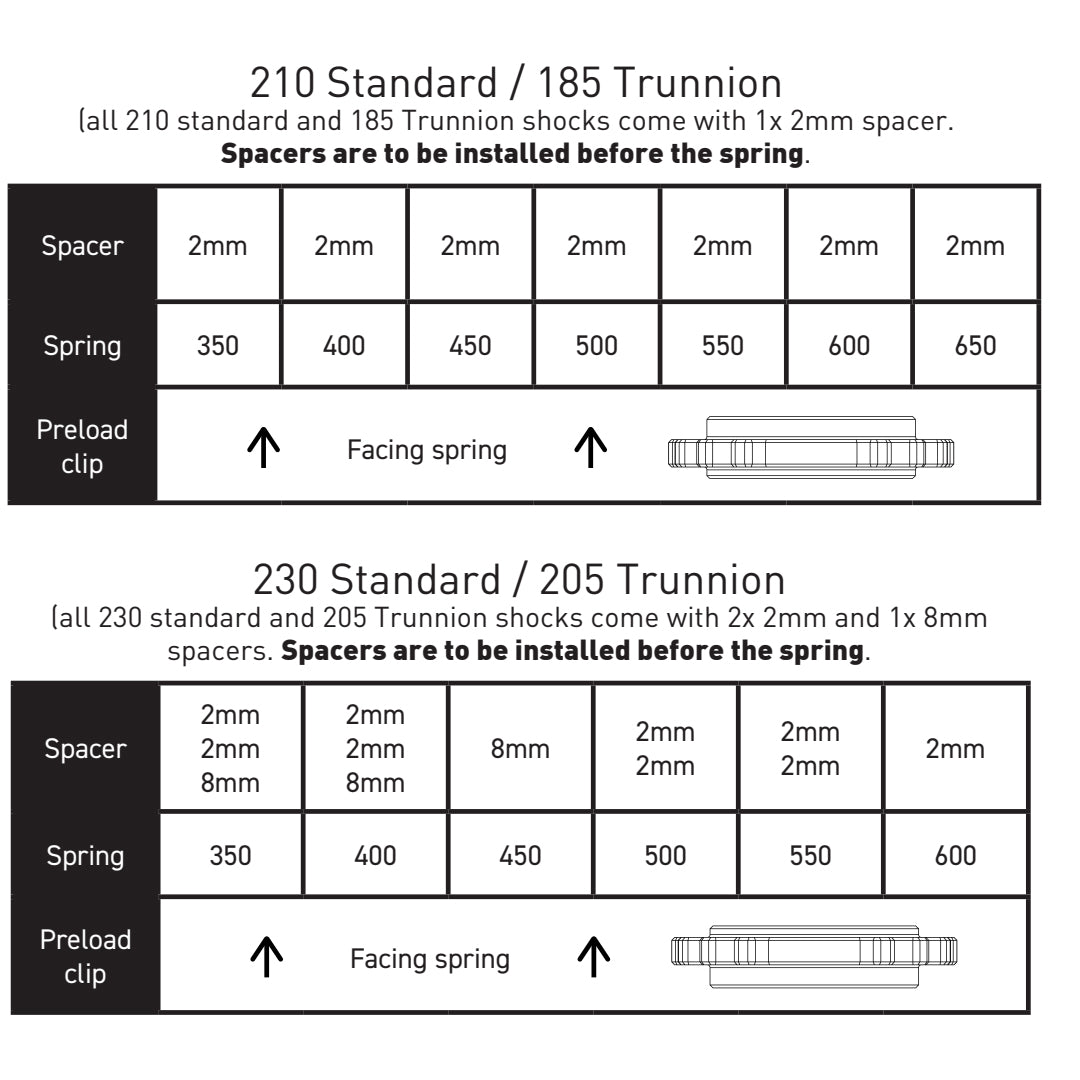

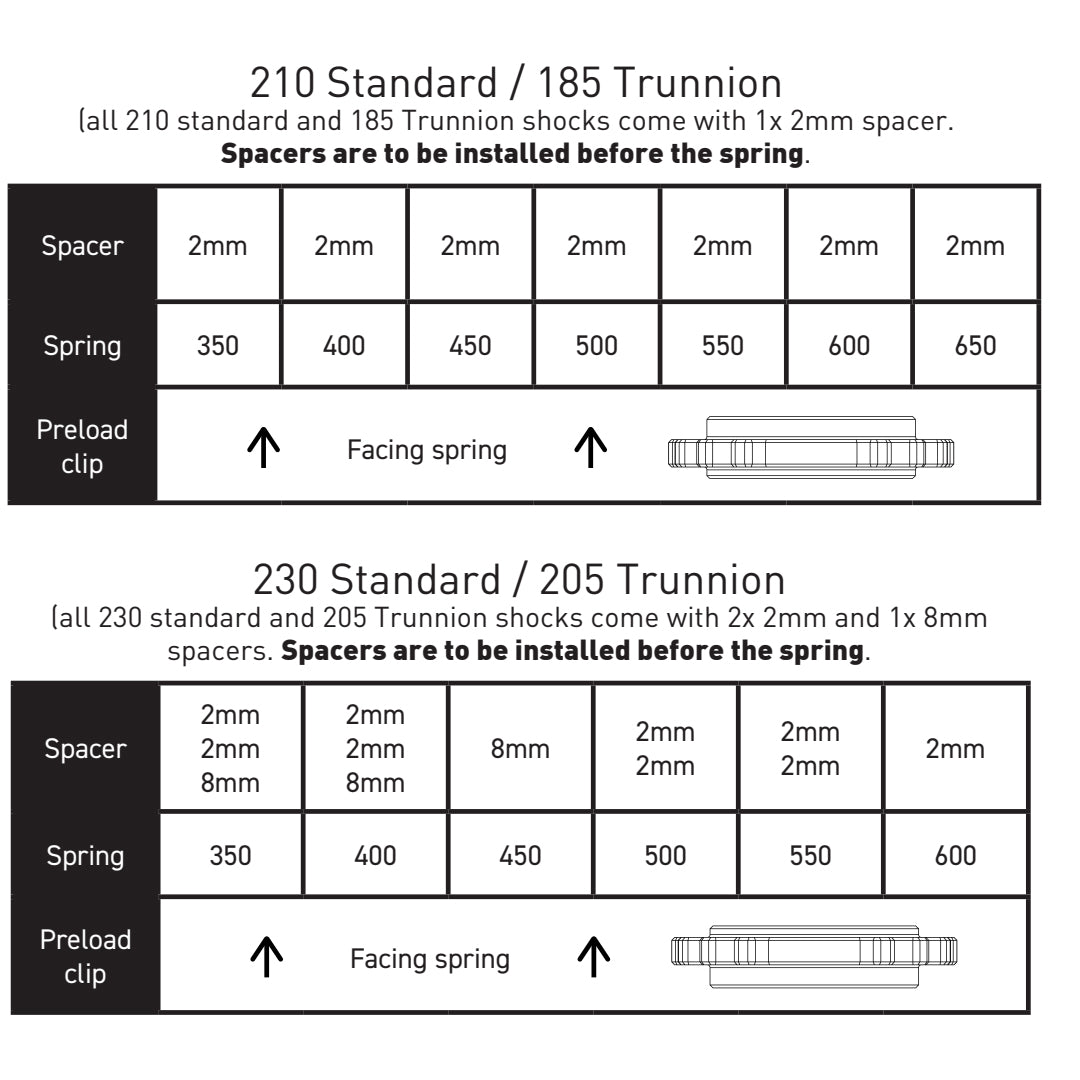

Tigon Preload Clip & Spacer Chart

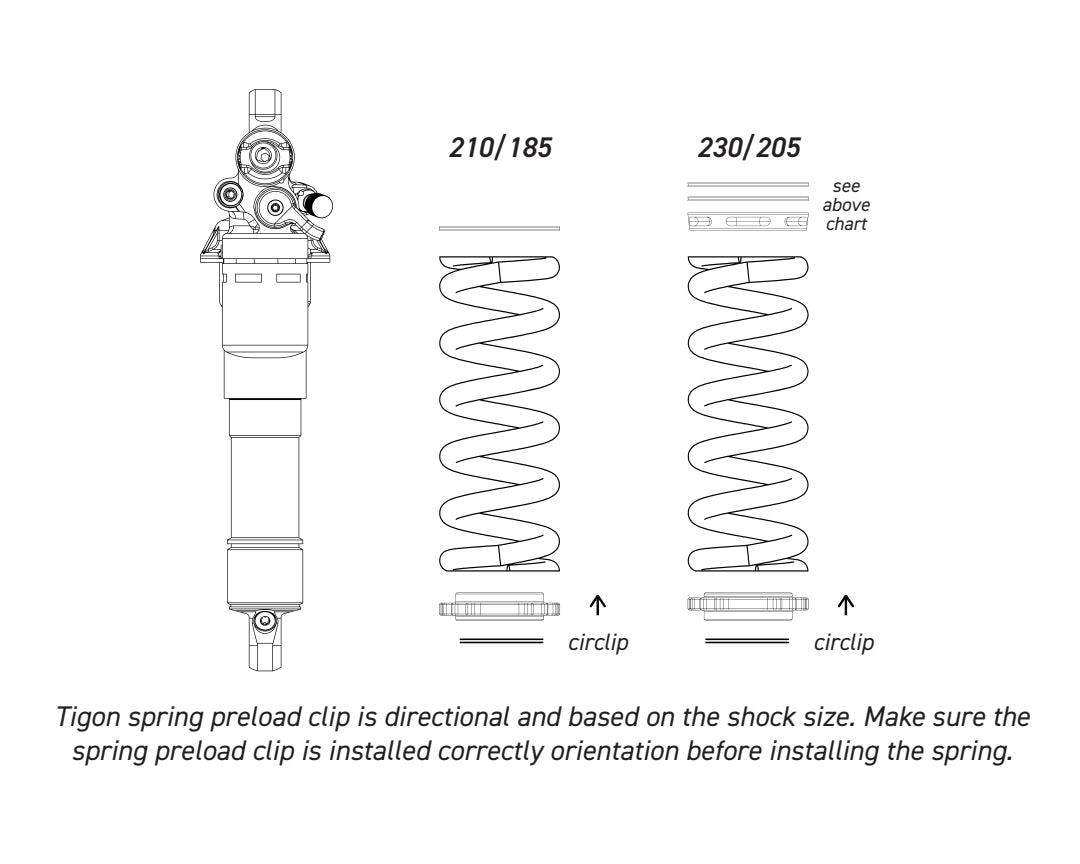

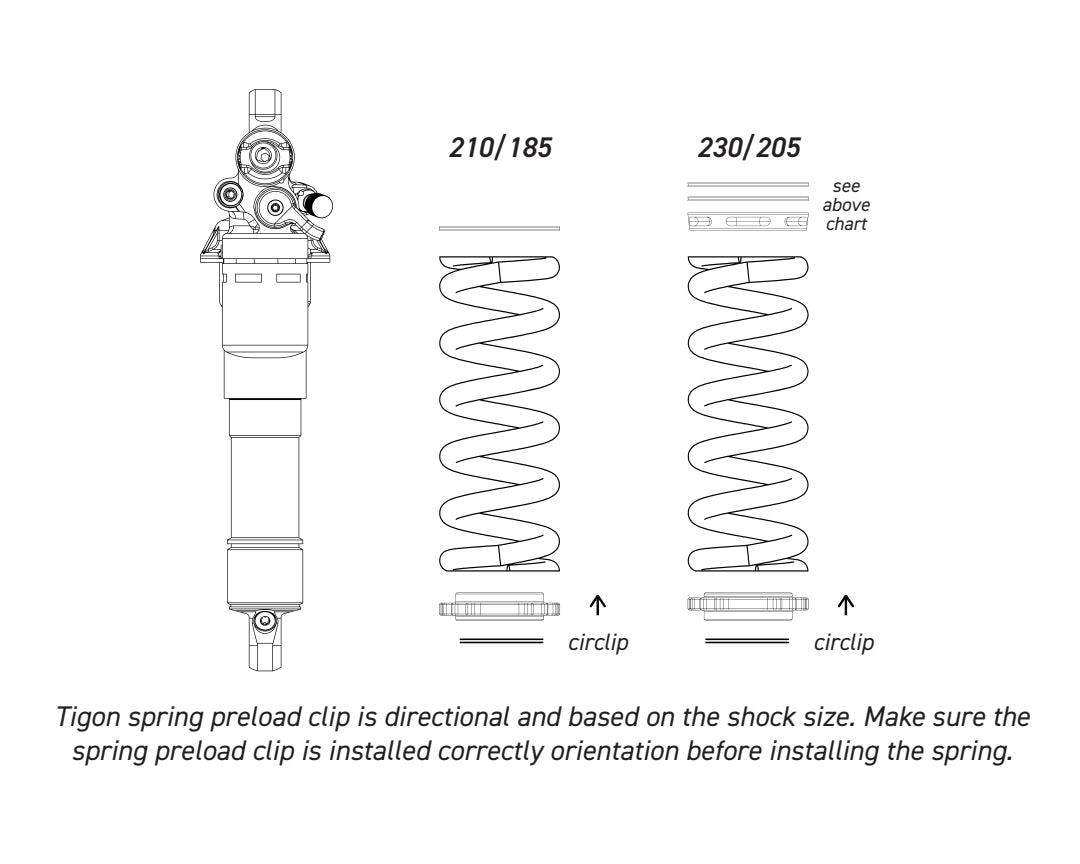

Tigon Preload Clip & Spacer Orientation

Spring Spacer Install

Spring Install

Spring Preloader Install

Spring Preloader Clip Install

Spring Preloader Clip Installed