HELM MKII Damper Side (Air & Coil) 100 Hour Service (Part 1 of 2)

HELM MKII Damper Complete 100 Hour Service Instructions

Mar 2022 orig.

Table of Contents

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek forks have pressurized oil. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service. Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a fork still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

These service instructions cover the basic service procedures using standard service kits. If your suspension requires parts beyond standard replacement parts – CSU, compression rods, etc. – please consult your authorized Cane Creek service center or contact us at our Cane Creek Support Center.

Service Notes

These instructions cover just the damper leg of a complete 100 hour service. Combine these instructions with the appropriate spring side – air or coil; original or MKII – and 50 hour lower service to get a complete 100 hour fork service.

Additionally, follow these instructions for damper removal and reinstall if sending the damper off for a service with an authorized Cane Creek service center.

Service Kit

BAG0713 – HELM MKII Damper Rebuilt Kit

Required Cane Creek Tools

BAG0405 – Compression Retaining Nut Socket – Thin Walled 11mm socket

AAG0086 – HELM Cartridge Fill Tool

AAG0367 – HELM Oil Seal Head Bullet

AAG0406 – HELM Compression Outer Sleeve Spanner

Additional Tools & Supplies

Allen wrenches – 4mm

Torx wrenches – T10

Sockets – 10, 13 & chamfer-less 30mm

Crowfoot wrenches – 10, 18, 20 & 22mm

Open Ended Box wrenches – 10, 18, 20 & 22mm

10mm Shaft Clamp

Torque wrenches

Knipex pliers

Pick

Suspension Grease

PolyLube Grease

Motorex 2.5wt Racing Fork Oil

Vacuum Oil Fill Machine

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

| Rebound Adjuster | 5 Nm | 243 (Blue) |

| Damper Top Cap to Gold Coupling | 9 Nm | None |

| Oil Seal Head to Damper Tube | 13 Nm | None |

| Damper Install | 36 Nm | 243 (Blue) |

| Compression Nut | Hand Tight | 243 (Blue) |

| LSC Knob Screw | 1.6 Nm | 243 (Blue) |

Oil Chart

| Oil Location | Oil Type | Oil Amount |

|---|---|---|

| Damper Fill | Motorex 2.5wt Racing Fork Oil | Fill to 2 Bars |

Related Technical Service Bulletins

Review all related TSBs before performing any service.

No specific HELM MKII damper TSBs at this time.

Lower Assembly Removal

Prior to beginning damper service, remove the lower assembly per the 50 hour service instructions.

Removing CSU from Lowers 1

Removing CSU from Lowers 2

Damper Removal

Step 1 – Low Speed Compression Nut Removal

Secure CSU. Using T10 Torx, remove Low Speed Compression knob screw. Remove LSC knob. Using thin walled 11mm socket (BAG0405), remove Low Speed Compression retaining nut. Remove High Speed Compression adjustor. Remove Low Speed Compression take up adaptor.

LSC Knob Screw Removal 1

LSC Knob Screw Removal 2

LSC Knob Removal

LSC Knob Removed

LSC Retaining Nut Socket

Putting Socket on LSC Retaining Nut

Freeing LSC Retaining Nut

HSC Knob Removed

LSC Take Up Adaptor Removal

Closing LSC Needle

Step 2 – Damper Removal

Remove High Speed Compression adjustor. Using 30mm chamferless socket, remove damper assembly. Breaker bar may be necessary.

High Speed Knob Removal

High Speed Knob Removed

Socket on Damper

Freeing Damper

Damper Removal

Damper Removed

Step 3 – Damper & CSU Inspection

Clean excess oil from damper assembly and inspect. Clean and inspect CSU. Remove and discard sag o-ring. Clean all small parts in solvent.

Cleaning Damper

Cleaning CSU

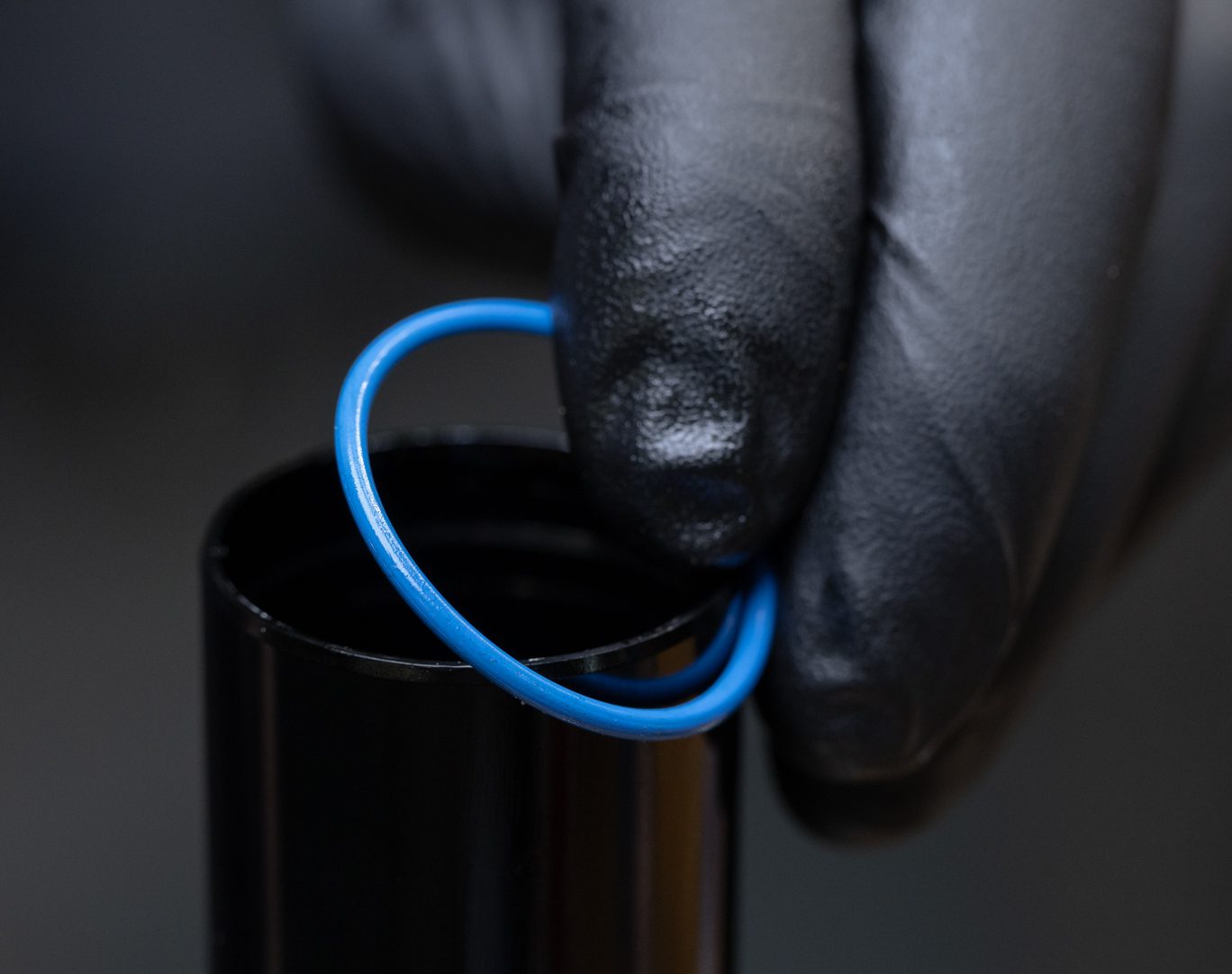

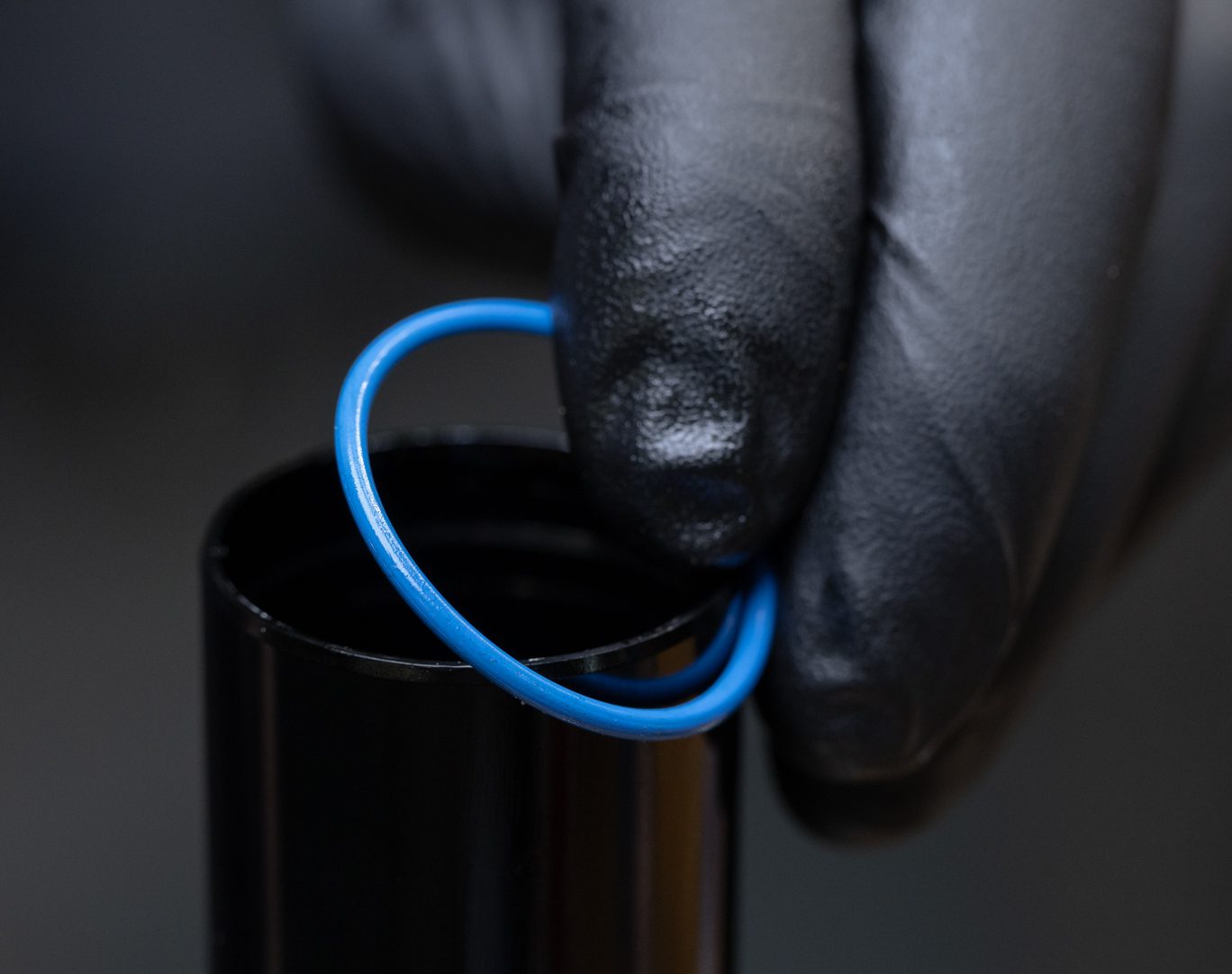

Sag O-Ring Removal

Cleaning Small Parts

Damper Disassembly

Step 1 – Oil Seal Head Removal

***Do not clamp damper tube. It will collapse.***

Using Knipex or vise, secure damper on gold damper coupling. Use 22mm open end wrench to loosen oil seal head. Remove oil seal head and rebound circuit using a circular motion. Discard damper oil in appropriate container.

Clamping Damper Coupler (Knipex)

Clamping Damper Coupler (Vise)

Tool on Oil Seal Head (Open End)

Tool on Oil Seal Head (Crowfoot)

Freeing Oil Seal Head

Unthreading Oil Seal Head

Oil Seal Head Unthreaded

Oil Seal Head & Rebound Circuit Removed

Disposing Damper Oil

Step 2 – Compression Circuit Disassembly

***Use caution when removing Low Speed needle. Ensure damper shaft is not compressed and top of damper is pointing away from harm in case oil and/or needle have pressure.***

Remove Low Speed needle from top of damper using 4mm Allen. Clamp damper coupling in vise. Using 30mm socket on top cap while simultaneously holding bladder with hand, loosen entire assembly above damper coupling. Remove bladder assembly, compression check spring and compression piston assembly. Ensure the actual poppet comes out with the piston assembly.

LSC Needle Removal 1

LSC Needle Removal 2

Damper Clamped for Disassembly

Bladder Cleaning for Improved Grip

Turning Complete Damper Assembly

Complete Damper Assembly Removal

Compression Check Spring Removal

Compression Poppet & Piston Assembly Removal

Compression Poppet & Piston Assembly Removed

Step 3 – Compression Outer Sleeve Disassembly

Using Compression Outer Sleeve Spanner (AAG0406) and 30mm socket, unthread top cap from compression outer sleeve. Remove top cap, helix and claw from outer sleeve. Remove and discard bladder from outer sleeve.

Compression Sleeve Spanner

Compression Sleeve Spanner on Sleeve

Unthreading Top Cap from Compression Sleeve

Removing Top Cap from Compression Sleeve

Helix Removed

Claw Removal

Bladder Removal

Compression Assembly Disassembled

Step 4 – Rebound Circuit Disassembly

Thoroughly clean rebound assembly. Using 10mm shaft clamp, clamp damper shaft between seal head and rebound adjuster. Using 10mm open ended wrench, remove adjuster. Remove and discard o-ring from rebound adjuster, oil seal head, and piston band from rebound piston.

Always use extreme caution when using a pick in this step or others to avoid scratching metal parts. Failure to do this can create scratches in the o-ring glands which cause leak paths for oil or air. When possible, pinch and remove o-rings rather than using a pick.

Assembly Clean

Rebound Shaft Clamped for Disassembly

Freeing Rebound Adjuster

Unthreading Rebound Adjuster

Rebound Adjuster Removal

Oil Seal Head Removal

Rebound Adjuster O-Ring Removal

Air Piston Band Removal

Continue to Part 2

Next