DBcoil CS Complete 100 Hour Service Instructions (Part 3 of 3)

May 2022 orig., July 2022 rev.

Table of Contents

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek shocks have pressurized nitrogen and oil, even coil shocks. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service.

Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a shock still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

These service instructions cover the basic service procedures using standard service kits. If your suspension requires parts beyond standard replacement parts – shaft, damper tubes, end eyes – please consult your authorized Cane Creek service center or contact us at our Cane Creek Support Center.

Service Notes

The DBair CS and Coil CS share many service steps. Additionally, the Standard and Trunnion variants of both models have identical service procedures other than where to clamp the cylinder head. Some images in these instructions may not be identical to the valve body or outer damper tube on the Coil CS, but process is the same for the shock in the image and the shock on your bench.

Additionally, running changes happened throughout the lifespan of the Coil CS. Many of those are addressed in the Technical Service Bulletins below, but always take note of the way the shock is originally built and replicate that during reassembly to maintain the original performance, tune, set up, etc.

8mm Shafts

In 2018, all Coil CS shocks transitioned from 8mm to 9.5mm shafts to be more compatible with modern higher leverage ratio bikes. Factory service support is no longer available for 8mm shafts outside of 9.5mm shaft upgrade kits. If you are interested in maintaining an 8mm shaft on a shock, please consult your authorized Cane Creek service center.

Service Kits

BAD2376 – DBcoil CS Complete Rebuild Kit

If 8mm shaft present, ONE of the following 9.5mm shaft upgrade kits is required (plus any stroke reduction clips needed from full stroke):

BAD1599 – 9.5mm Shaft Assembly – 200x57mm

BAD1600 – 9.5mm Shaft Assembly – 216x63mm

BAD1601 – 9.5mm Shaft Assembly – 222x70mm

BAD2322 – 9.5mm Shaft Assembly – 230x70mm

BAD0356 – 9.5mm Shaft Assembly – 240x76mm

BAD1603 – 9.5mm Shaft Assembly – 267x90mm

Required Cane Creek Tools

DBT018 – DB Seal Head Pin Spanner Wrench

AAD1361-01 – DBCoil/ DBAir – Oil Fill Needle Adapter

DBT016 – DB Gas Fill Needle

AAD0555 – 8mm & 9.5mm Shaft Clamp

AAD0756 – DB Valve Seat Tool

BAD1298 – DBcoil Seal Head Bullet

DBT012 – DB IFP Setting Tool

Additional Tools & Supplies

Allen wrenches – 1.5 & 3mm

Torx wrenches – T20

Sockets – 13mm

Crowfoot wrenches – 1/2″

9.5mm Shaft Bullet

Torque wrenches

Pick

Pin Spanner

Needle Nose Pliers

Strap wrench

Suspension Grease

PolyLube Grease

Motorex 4wt Racing Fork Oil

Vacuum Oil Fill Machine

Nitrogen Fill System

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

| Shaft Nut | 13.5 Nm | 243 (Blue) |

| Climb Switch Plate Cover | 0.16 Nm | 243 (Blue) |

| Outer Damper Tube | Tight | 263 (Red) |

| Valve Seat | 4.8 Nm | None |

| Climb Switch Screw | 1.2 Nm | 243 (Blue) |

| Oil Seal Head | 15 Nm | None |

Oil Chart

| Oil Location | Oil Type | Oil Amount |

|---|---|---|

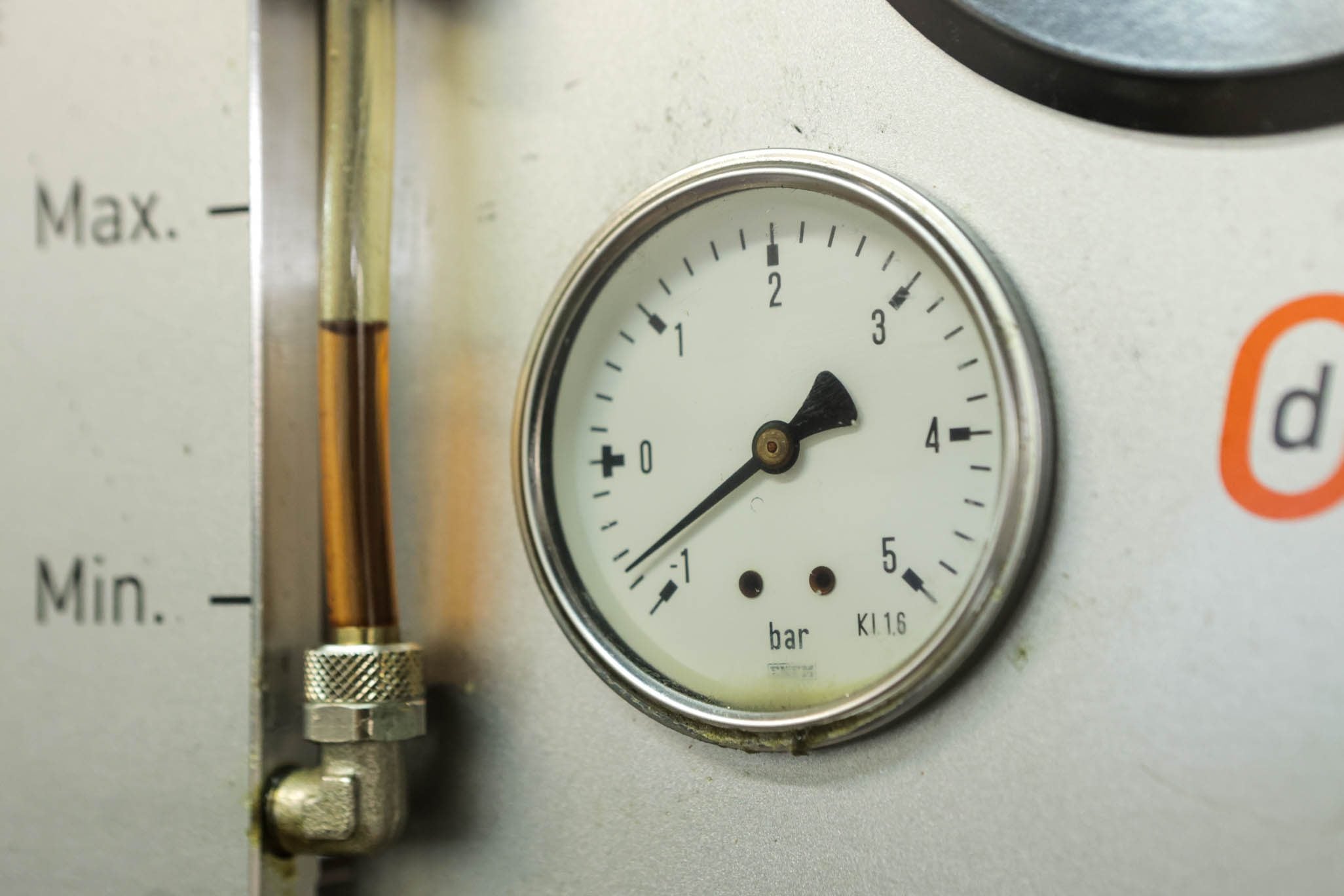

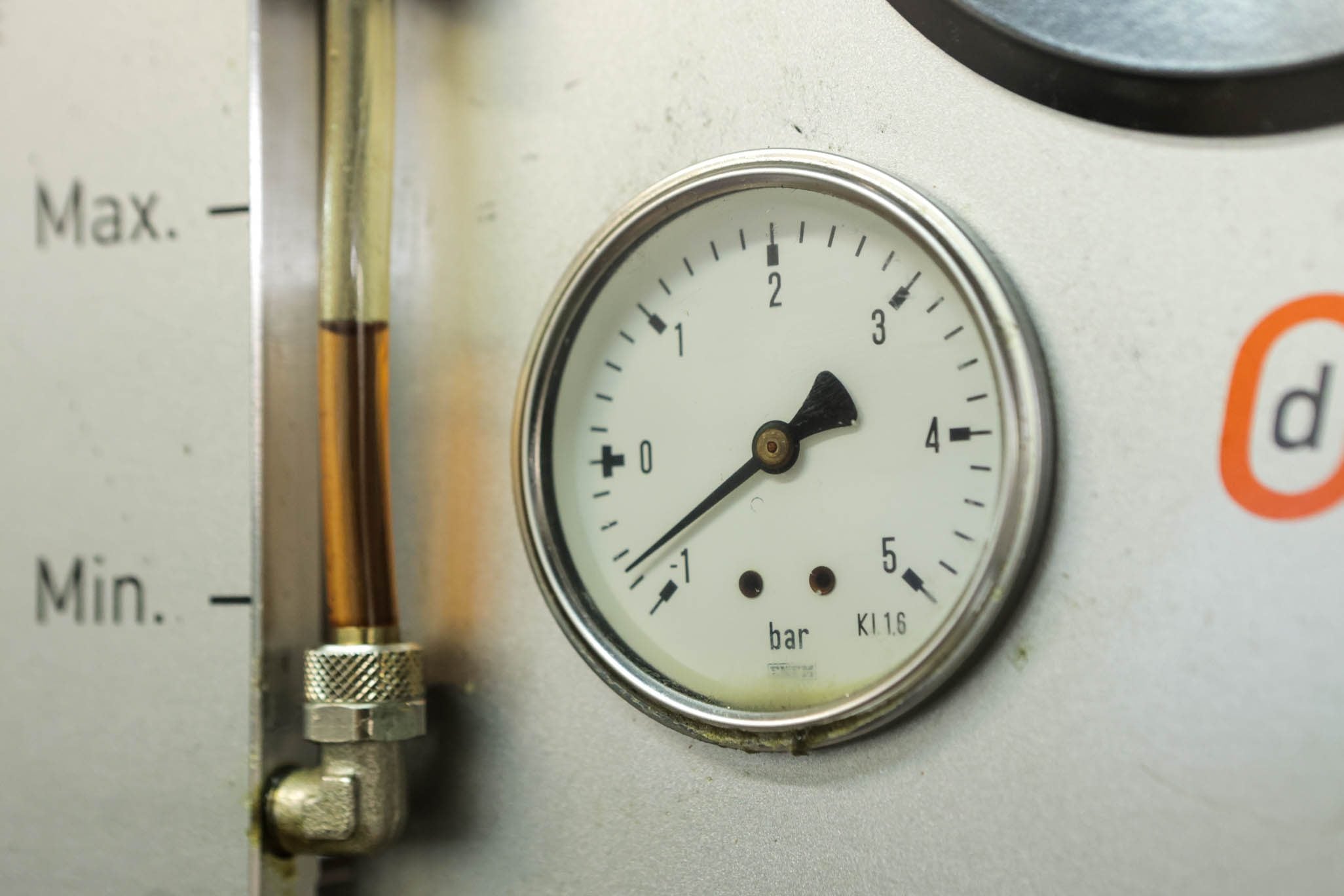

| Damper Fill | Motorex 4wt Racing Fork Oil | Fill to 3 Bars |

Nitrogen Chart

| Nitrogen Location | Nitrogen Pressure |

|---|---|

| Valve Body | 11 - 12 Bars |

Damper Fill

Step 1 – Setting IFP Depth

Thread IFP tool into IFP until bottomed. Push into reservoir tube until bottomed. Slide plunger into res tube. Install res end circlip. With IFP bottomed, slide the plunger out until contacting circlip. Lock plunger in place. Lock spacer in place onto top of plunger. Loosen plunger and pull IFP out 5mm. Relock plunger in position to set IFP depth.

IFP Setting Tool Threaded into IFP

Bottoming IFP in Reservoir Tube

Plunger Inserted into Reservoir Tube

Reservoir Tube Circlip Install

Reservoir Tube Circlip Installed

Ensuring IFP Stays Bottomed Out in Res Tube

Sliding Plunger Up to Res Tube Circlip

Plunger Seated on Res Tube Circlip

Plunger Locked in Place, Spacer Seated & Locked On Plunger

Loosening Plunger from IFP Tool Shaft

Setting Plunger w/ IFP Now Set at 5mm

Confirming IFP Set at 5mm

Step 2 – Prepping Shock for Fill

Temporally install end eye. Install fill port o-ring (.DB11102). Attach oil fill needle to fill port. Attached to fill machine per manufacturer instructions.

Oil Fill Port O-Ring Installed

Attaching Fill Needle to Fill Port

Attached to Fill Machine

Step 3 – Vacuum and Oil Fill Process

Vacuum system to (4) mbar. Pressure with Oil to (3) bar. Slowly cycle shaft finishing with shaft fully out. Cut fill and equalize pressure. Vacuum system to (4) mbar, leaving shaft out. Pressure again with Oil to (3) bar. Slowly cycle shaft finishing with shaft fully out. Cut fill.

Vacuum System to (4) mbar

Shaft Extended (On Factory IFP Setting Tool)

Shaft Compressed (On Factory IFP Setting Tool)

Oil Pre-Fill

Oil Fill to (3) bar

Step 4 – Valve Body Closure

Holding horizontal, disconnect fill machine. Drip some oil on to top of fill. Install oil fill screw with T20.

Dripping Fill Oil onto Fill Port

Installing Oil Fill Screw 1

Installing Oil Fill Screw 2

Oil Fill Screw Installed

Step 5 – Reservoir End Cap Install

Lightly grease and install reservoir end o-ring (.DB11119). Apply Royal Purple to wall of res tube. Install res end by pushing tube onto cap. Press res end cap in as necessary and install circlip.

Res End O-Ring Greased

Res End O-Ring Installed

Lubricating Res Tube Wall

Res End Install 1

Res End Install 2

Res End Circlip Install

Res End Circlip Installed

Step 6 – Nitrogen Fill

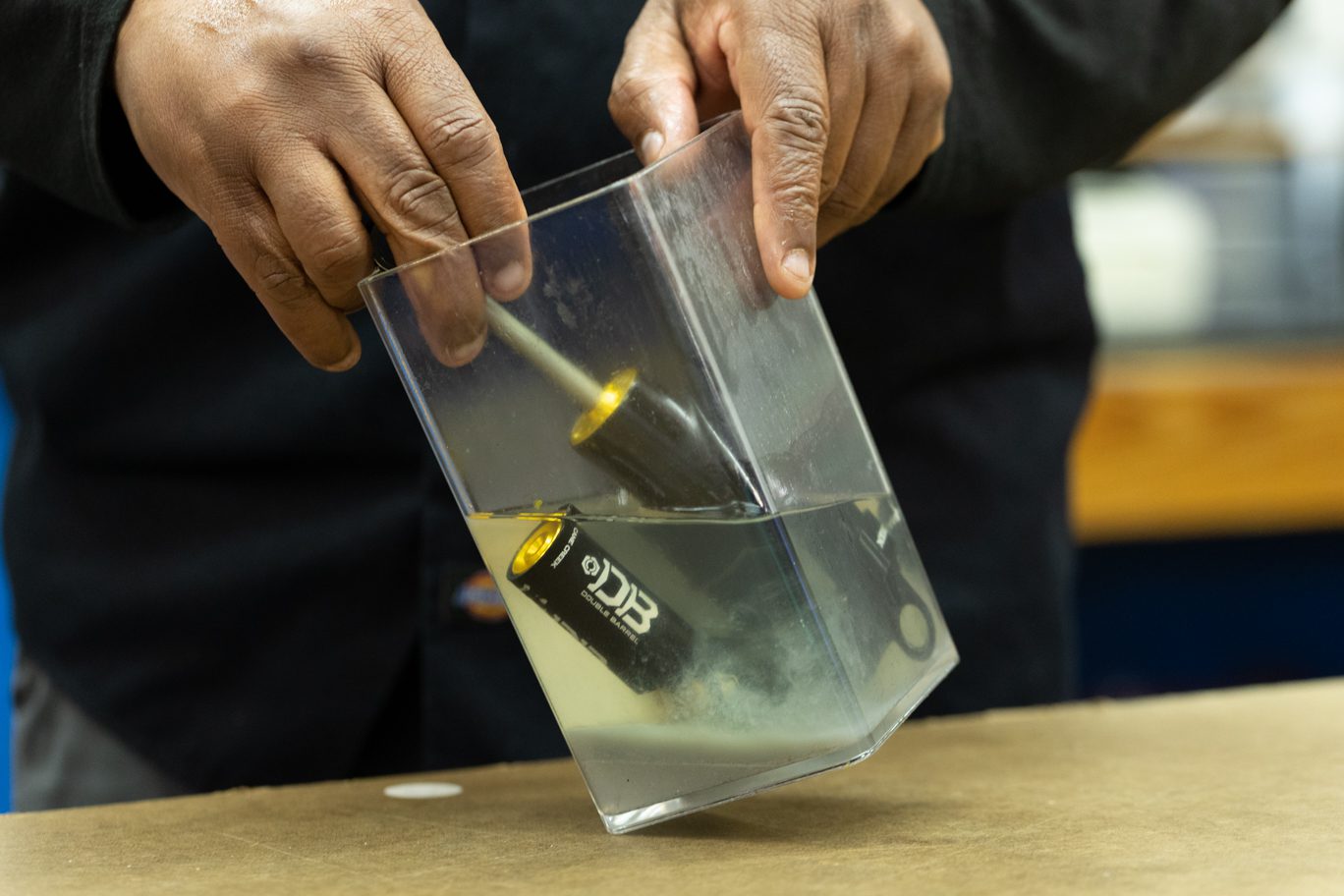

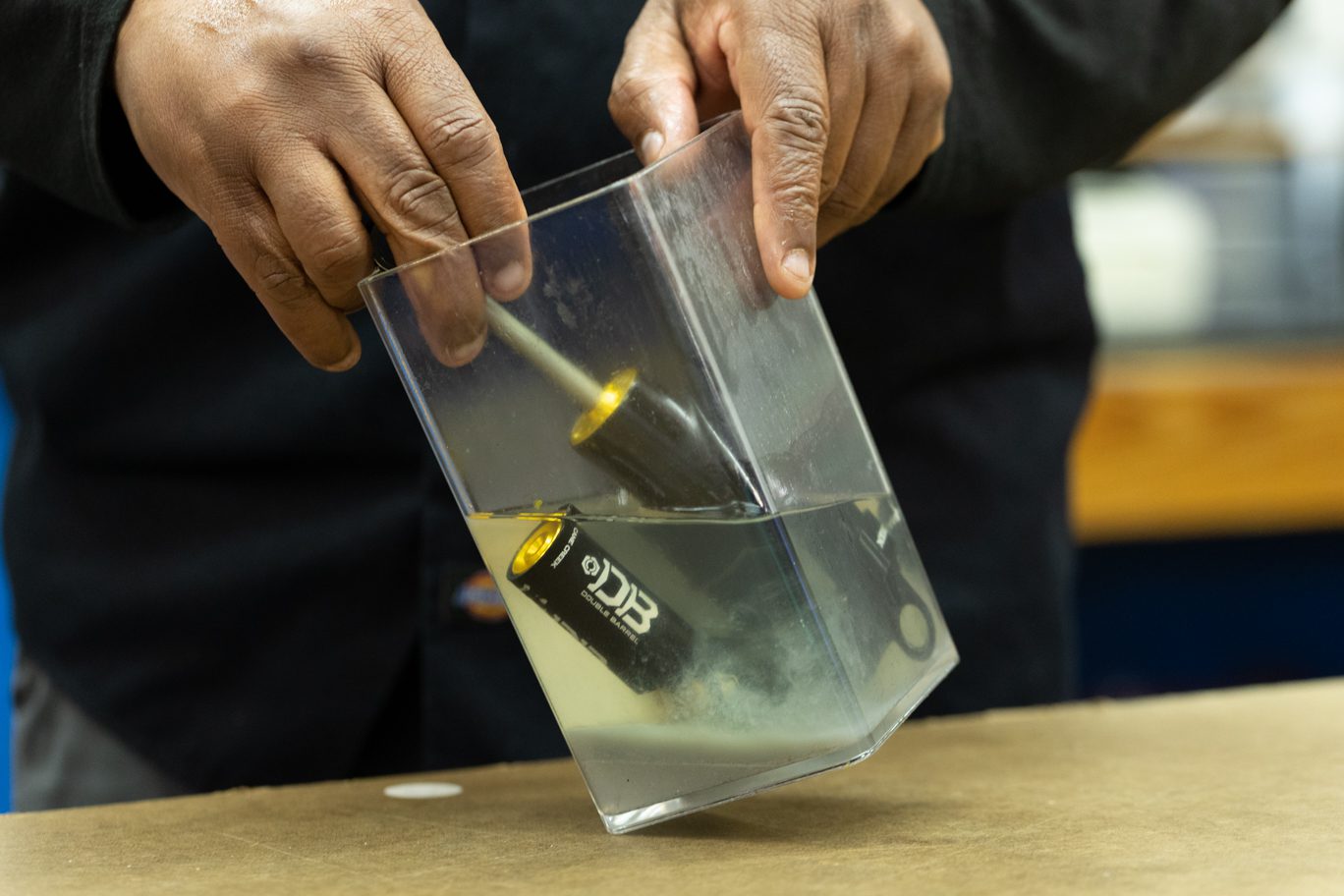

Insert gas fill needle in gas fill port on reservoir end cap. Pressurize to 11-12 bars of nitrogen. Compress shaft and ensure proper gas by observing shaft return to full extension. Submerge valve body in water to check for gas leaks. Install fill screw.

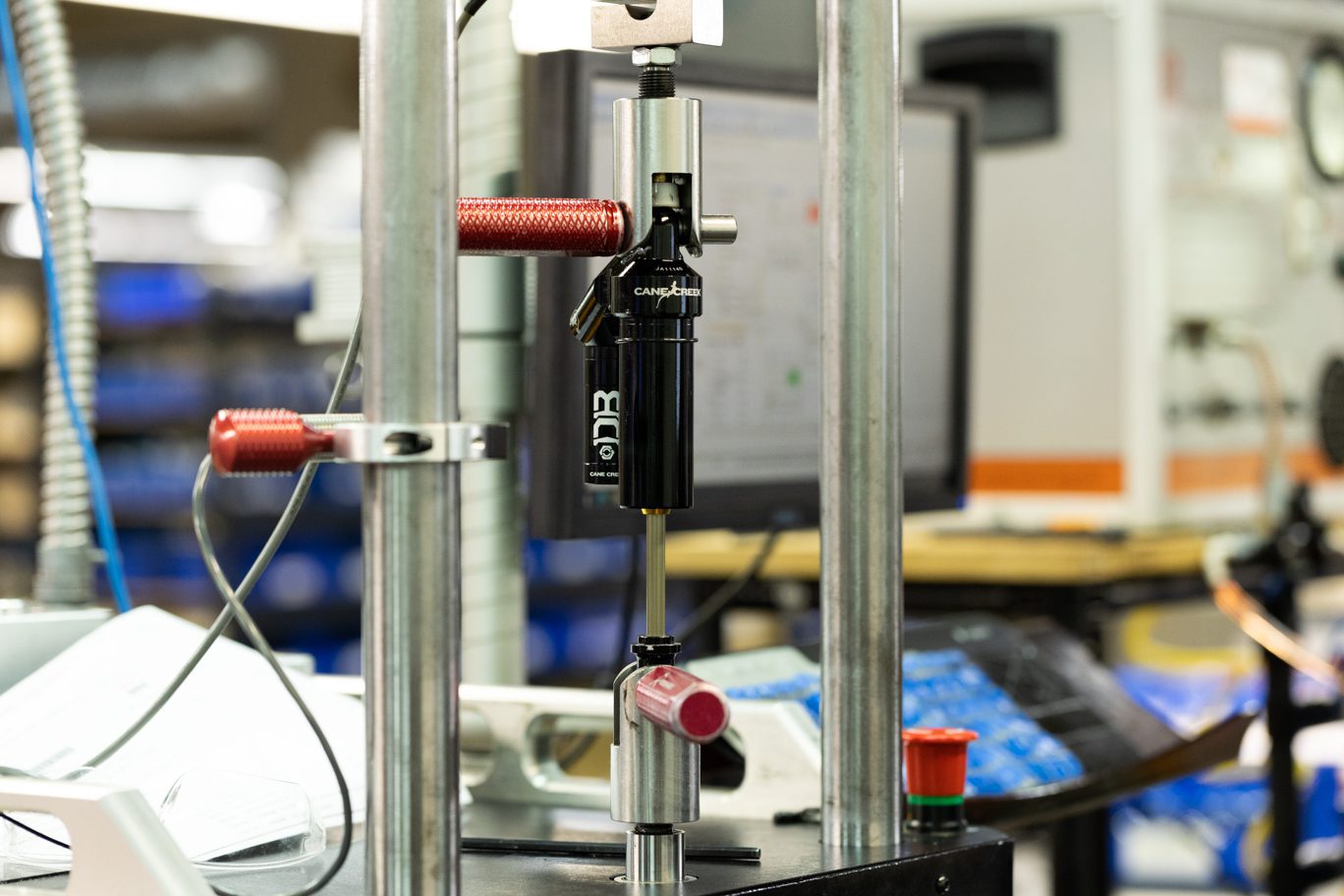

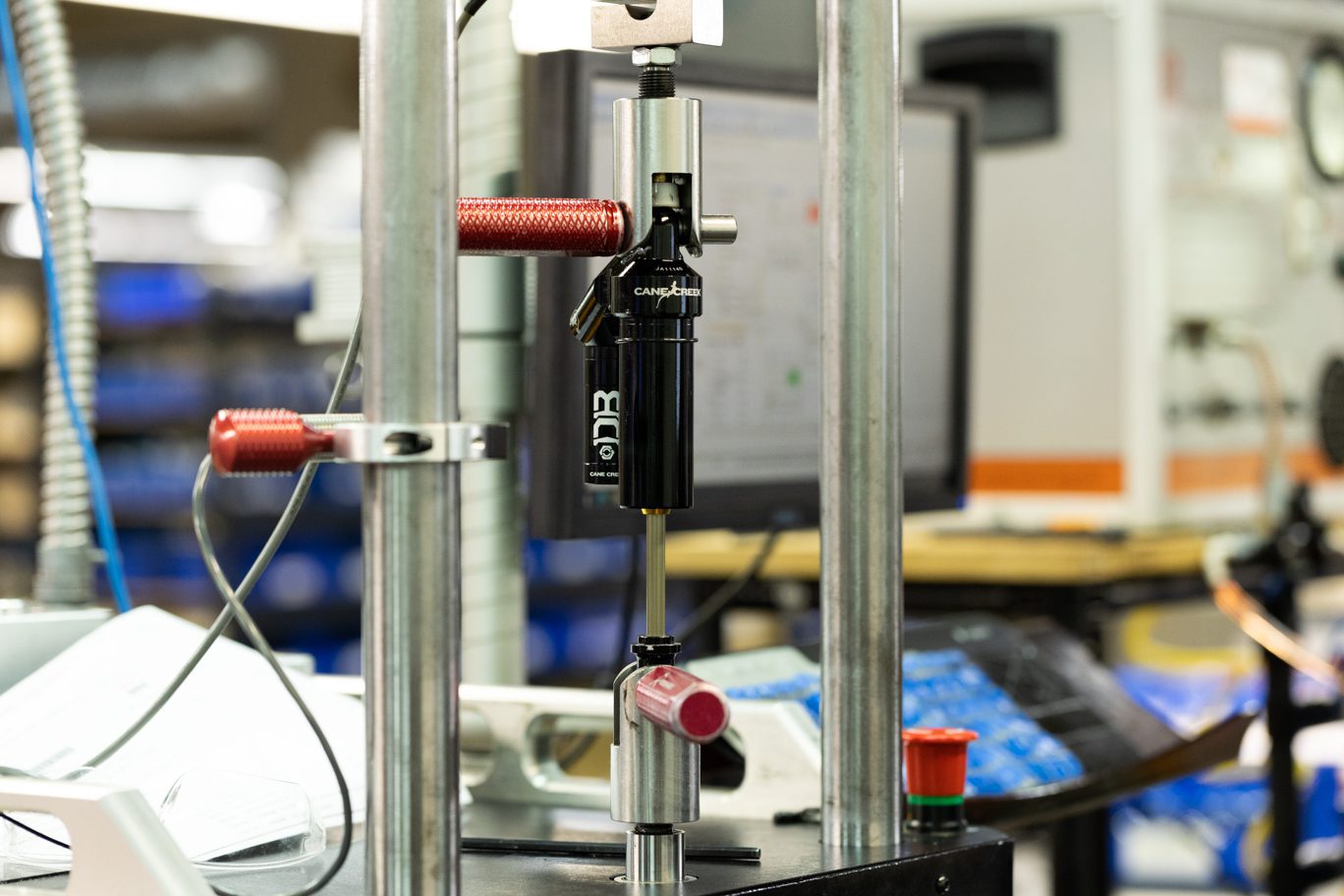

If mechanic dyno equipment is available, run shock on dyno at this point.

Insert Nitrogen Fill Needle

Nitrogen Fill Needle Inserted

Connect to Nitrogen Hose

Nitrogen Filled to Pressure

Compression Test 1

Compression Test 1

Gas Leak Test

Gas Fill Screw Install

Dyno Testing

Final Testing and Set Up

Step 1 – Dyno Test

Set adjusters to factory neutral. Using hand dyno, test shock for function. Ensure Climb Switch engages and operates properly. Turn individual adjusters to test each one. Set back to original tune if desired.

Step 2 – Spring Reinstall

Reinstall any stroke reducer clips as needed below bottom out bumper. Reinstall spring and spring clip. Install all necessary bushings and hardware.

Stroke Reduction Installed

Spring Install

Spring Clip Install