DBair CS Complete 100 Hour Service Instructions (Part 1 of 3)

June 2022 orig., June 2024 rev.

Table of Contents

Recommendations and Warnings

Cane Creek recommends only trained suspension technicians perform service on all suspension, using all required tools and following all proper procedures. Anyone without access to the proper equipment or with any concerns on the procedures should defer to an authorized Cane Creek service center for service. Improper service can result in loss of performance or suspension failure. All Cane Creek shocks have pressurized nitrogen and oil, even coil shocks. Follow the service procedures exactly as written to avoid possible injury or harm to the suspension. Always wear eye protection while performing suspension service.

Please dispose of all waste products and materials through proper channels to avoid contamination of the environment.

Any damage or issues resulting from improper service will not be covered by warranty. If you have a shock still in its original warranty period and do not wish to void your warranty, please contact an authorized Cane Creek service center.

These service instructions cover the basic service procedures using standard service kits. If your suspension requires parts beyond standard replacement parts – shaft, damper tubes, end eyes – please consult your authorized Cane Creek service center or contact us at our Cane Creek Support Center.

Service Notes

The DBair CS and Coil CS share many service steps. Additionally, the Standard and Trunnion variants of both models have identical service procedures other than where to clamp the cylinder head. Some images in these instructions may not be identical to the the valve body or outer damper tube on the Air CS, but process is the same for the shock in the image and the shock on your bench.

Additionally, running changes happened throughout the lifespan of the Air CS. Many of those are addressed in the Technical Service Bulletins below, but always take note of the way the shock is originally built and replicate that during reassembly to maintain the original performance, tune, set up, etc.

Service Kits

BAD0241 – DBair/DBair CS Air Spring Rebuild Kit

BAD2375 – DBair CS Damper Rebuild Kit

Required Cane Creek Tools

DBT018 – DB Seal Head Pin Spanner Wrench

AAD1361-01 – DBCoil/ DBAir – Oil Fill Needle Adapter

DBT016 – DB Gas Fill Needle

AAD0555 – 8mm & 9.5mm Shaft Clamp

AAD0756 – DB Valve Seat Tool

AAD1002 – DBair Air Seal Head Bullet

BCD0344 – Kitsuma/DBair/DBair IL Air Seal Head Tool

DBT012 – DB IFP Setting Tool

Additional Tools & Supplies

Allen wrenches – 1.5 & 3mm

Torx wrenches – T20

Sockets – 6mm

Crowfoot wrenches – 1/2″

Torque wrenches

Pick

Pin Spanner

Needle Nose Pliers

Strap wrench

Suspension Grease

PolyLube Grease

Motorex 4wt Racing Fork Oil

Royal Purple 10w-30

Vacuum Oil Fill Machine

Nitrogen Fill System

Torque, Loctite, Oil & Nitrogen Specs

Torque & Loctite Chart

| Part | Torque Spec | Loctite Spec |

|---|---|---|

| Shaft Bolt | 5 Nm | 243 (Blue) |

| Climb Switch Plate Cover | 0.16 Nm | 243 (Blue) |

| Outer Damper Tube | Tight | 263 (Red) |

| Valve Seat | 4.8 Nm | None |

| Climb Switch Screw | 1.2 Nm | 243 (Blue) |

| Oil Seal Head | 15 Nm | None |

| Air Piston Screws | 4 Nm | 243 (Blue) |

| End Eye | 4.8 Nm | 243 (Blue) |

| Inner Air Can/Air Seal Head | 22.6 Nm | None (PolyLube) |

Oil Chart

| Oil Location | Oil Type | Oil Amount |

|---|---|---|

| Air Can | Royal Purple 10w-30 | 8 mL |

| Damper Fill | Motorex 4wt Racing Fork Oil | Fill to 3 Bars |

Nitrogen Chart

| Nitrogen Location | Nitrogen Pressure |

|---|---|

| Valve Body | 11 - 12 Bars |

Related Technical Service Bulletins

General Prep

Clean shock. Record tune if desired. Remove hardware. Remove bushings if replacing. Remove valve cap. Bleed air from shock using shock pump. Be sure to depressurize shock slowly to avoid trapping air in the negative chamber.

TSB018 – DBair CS & DBcoil CS Eyelet Change

Shock Ready for Service

Hardware & Bushing Removed

Air Bleed

Air Spring Disassembly

Step 1 – Outer Air Can Removal

Remove air can retaining o-ring. Clamp shock in soft jaw vise. Using strap wrench, turn air can and pull down away from air seal head. Unclamp shock. Remove air can. Note and remove any air volume reduction.

Always use extreme caution when using a pick in this step or others to avoid scratching metal parts. Failure to do this can create scratches in the o-ring glands which cause leak paths for oil or gas. When possible, pinch and remove o-rings rather than using a pick.

Air Can Retaining O-Ring Removal

Air Can Retaining O-Ring Removed

Shock Clamped in Vise

Strap Wrench on Outer Air Can

Outer Air Can Freed

Volume Reduction Present

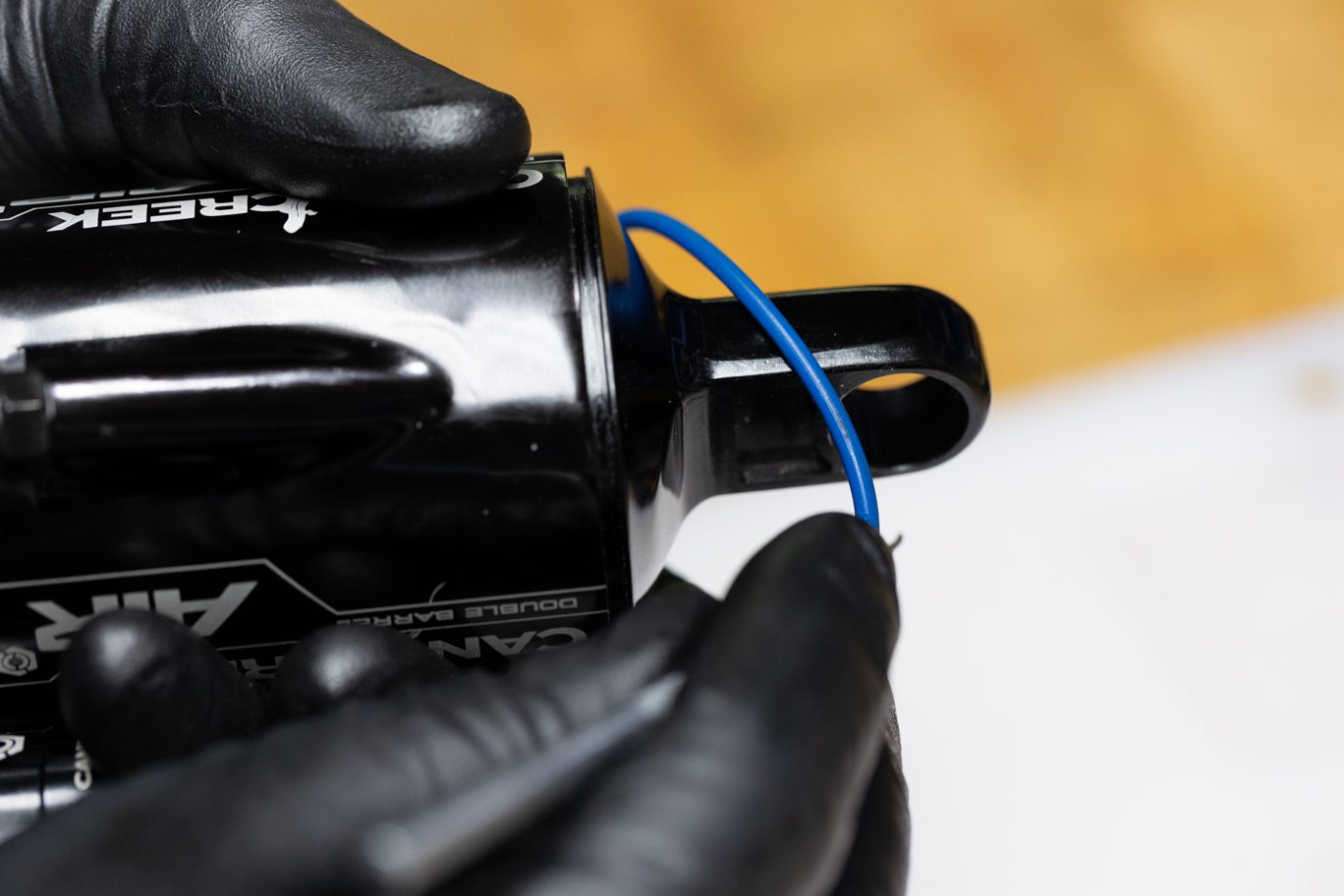

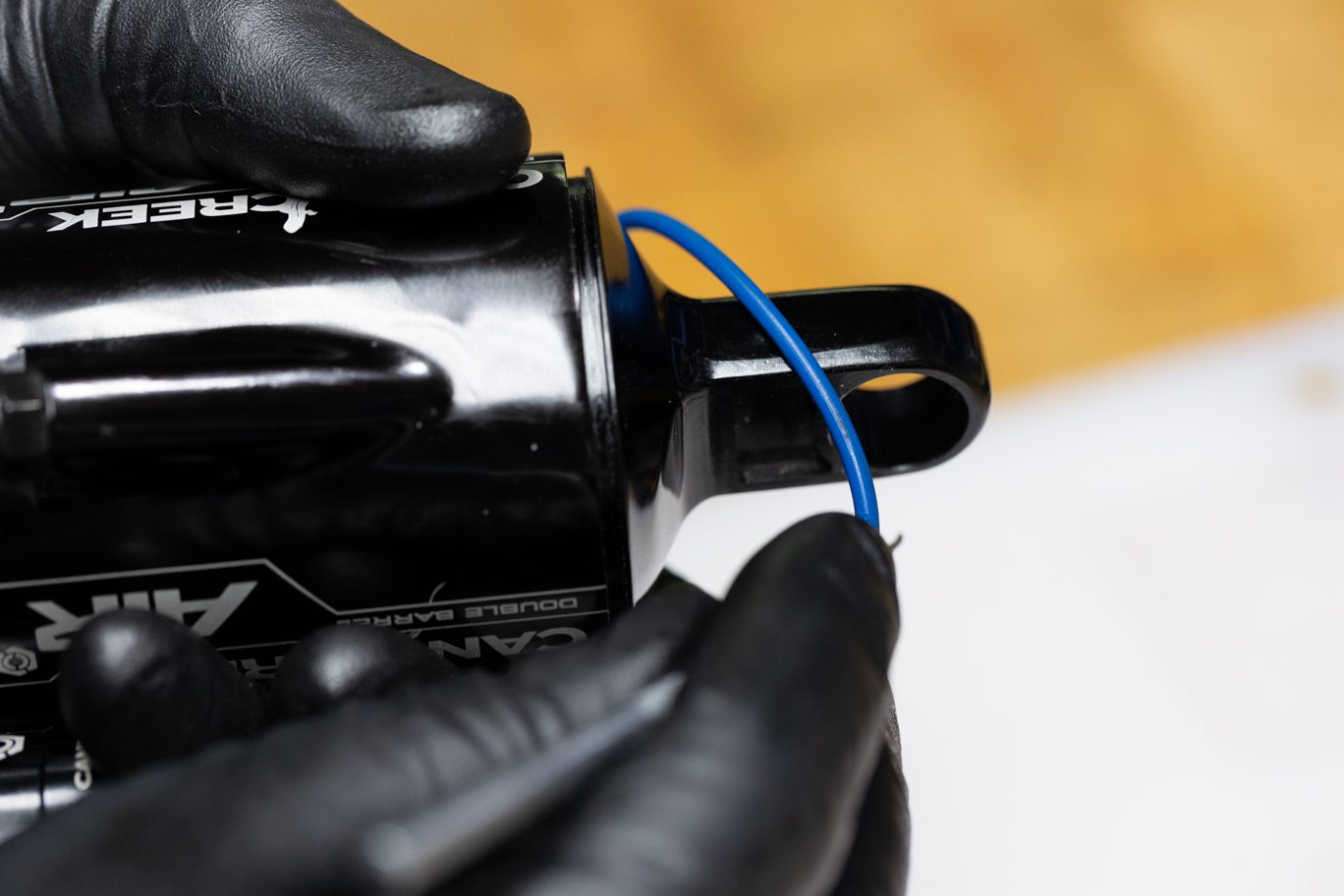

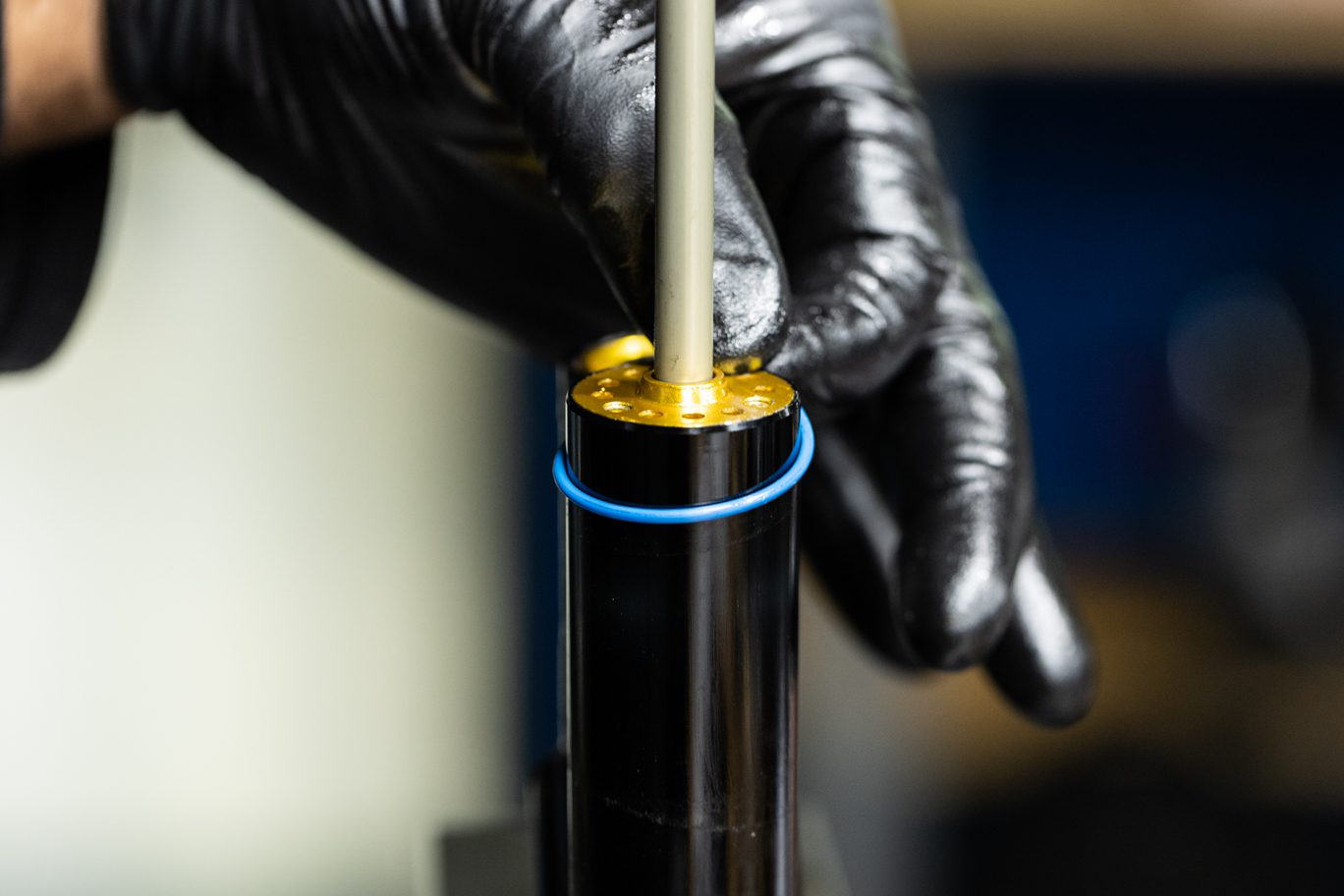

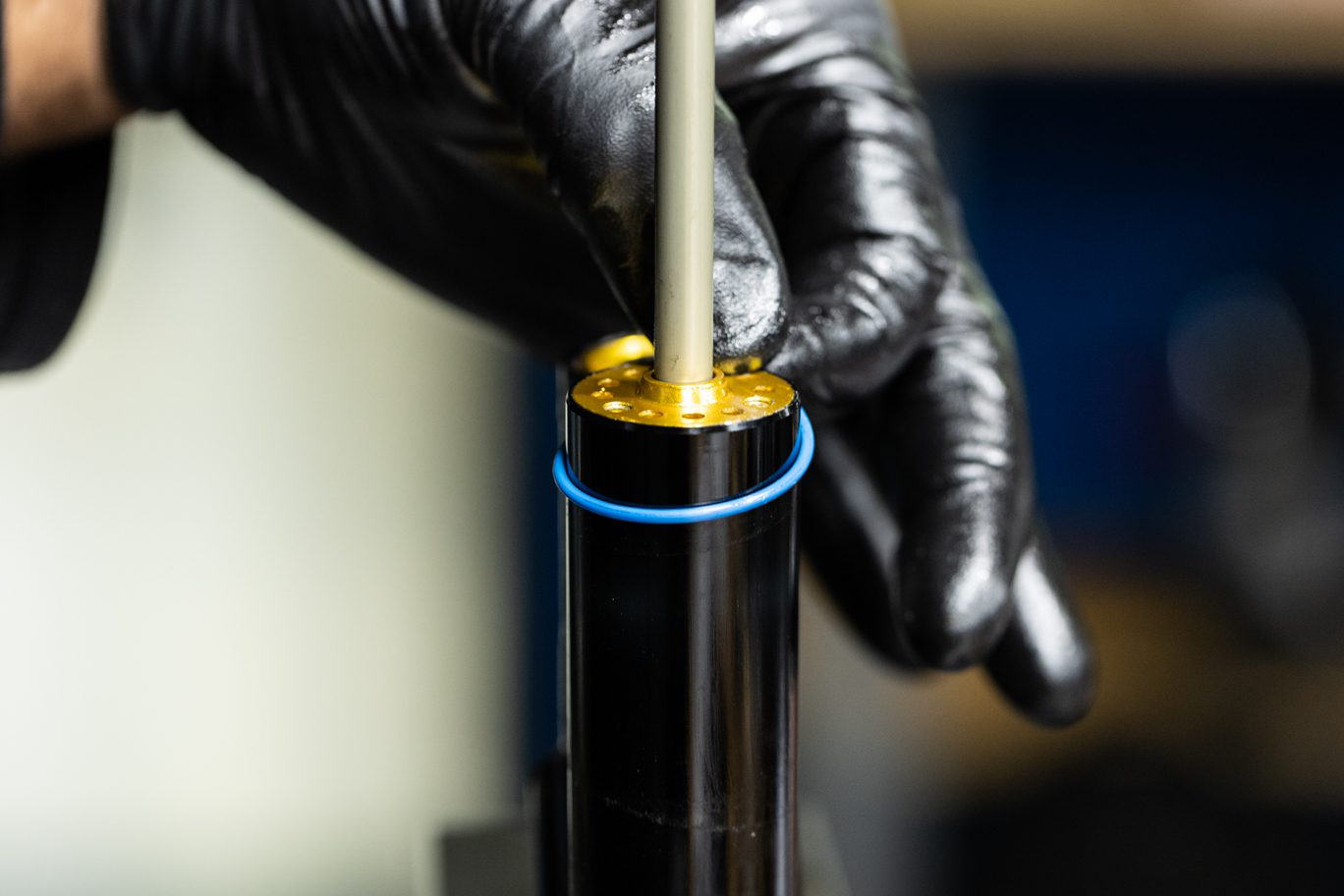

Step 2 – Freeing Inner Air Can & Air Seal Head

Reclamp shock. Align teeth on Air Seal Head Tool (BCD0344) with grooves on air seal head. Unthread air seal head from inner air can. Use strap wrench on inner air can to prevent rotation in end eye if necessary. Thoroughly clean inner air can with alcohol or other cleaner. Using strap wrench, remove inner air can from end eye.

Aligning Air Seal Head Tool on Seal Head

Air Seal Head Tool on Seal Head

Air Seal Head Freed from Inner Air Can

Cleaning Inner Air Can

Freeing Inner Air Can from End Eye

Inner Air Can Freed from End Eye

Step 3 – End Eye & Inner Air Can Removal

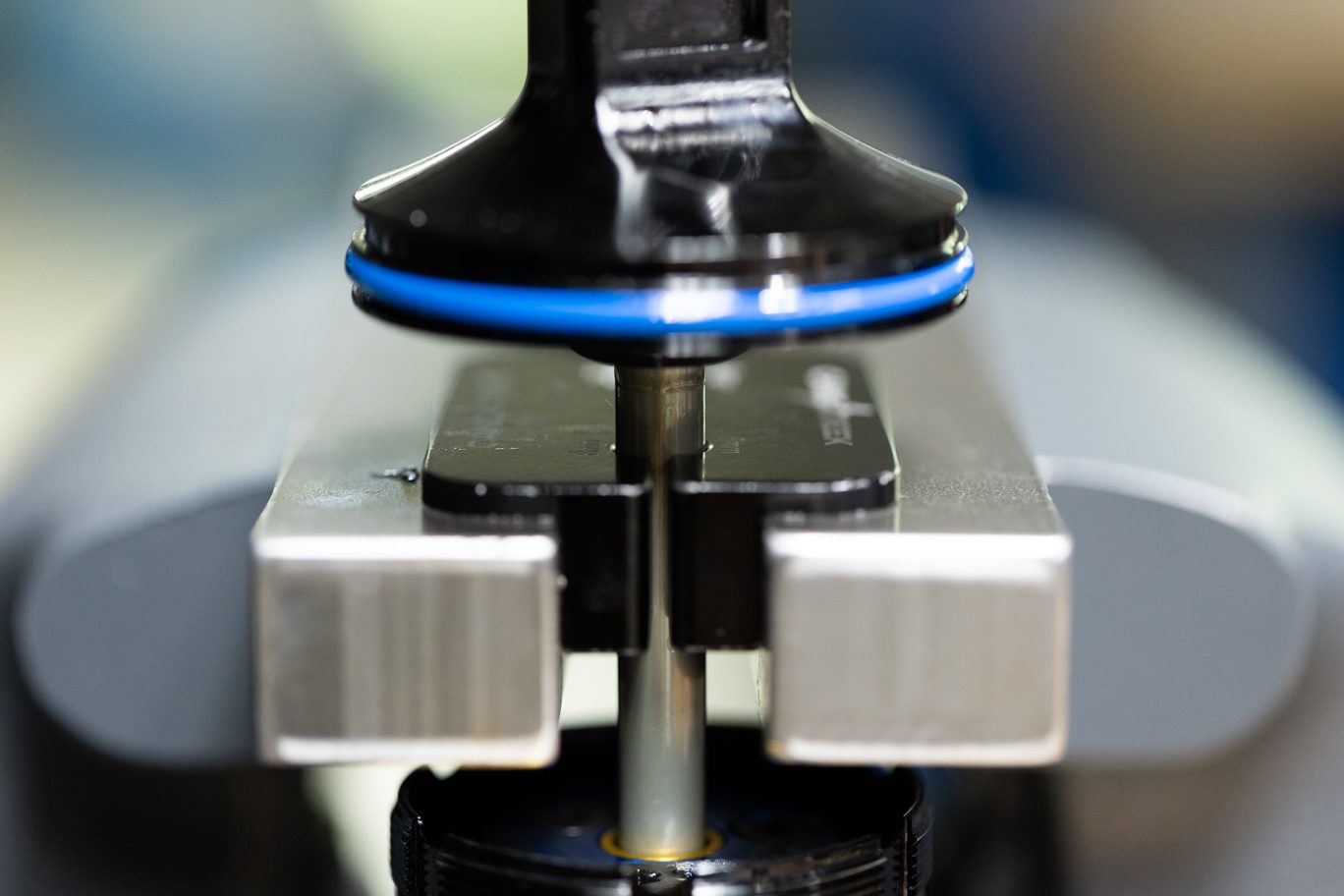

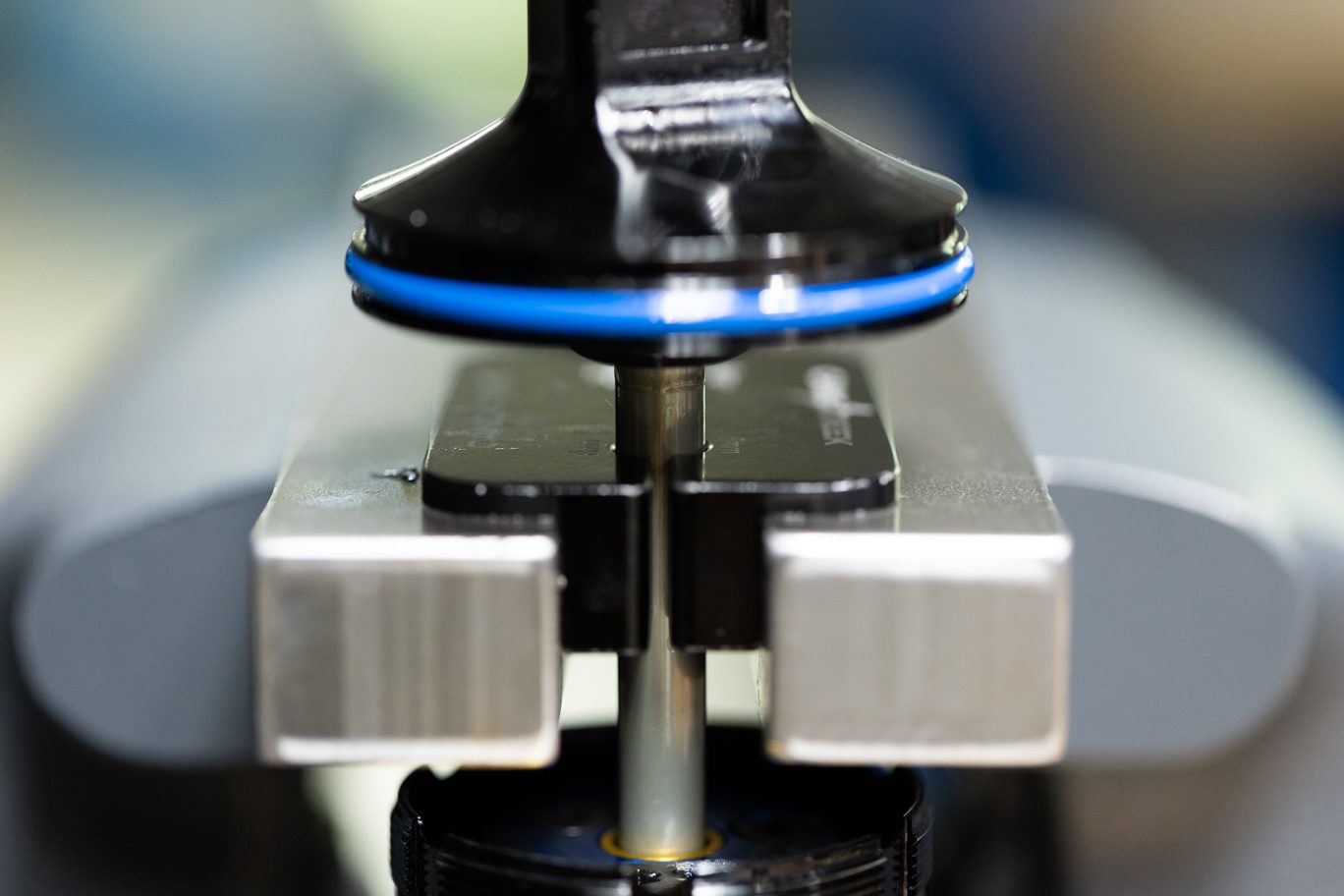

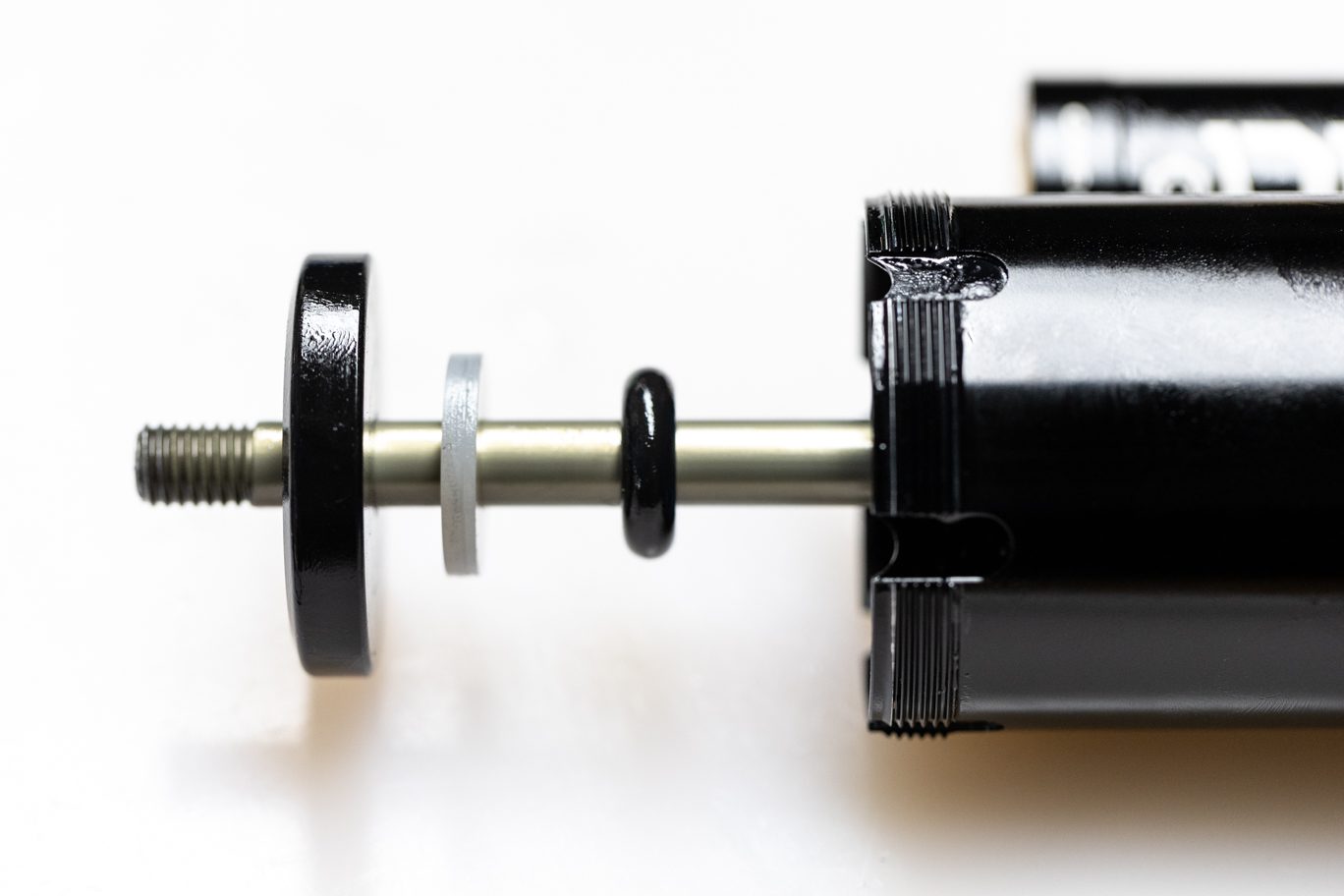

Clamp shaft in vise between end eye and inner air can.

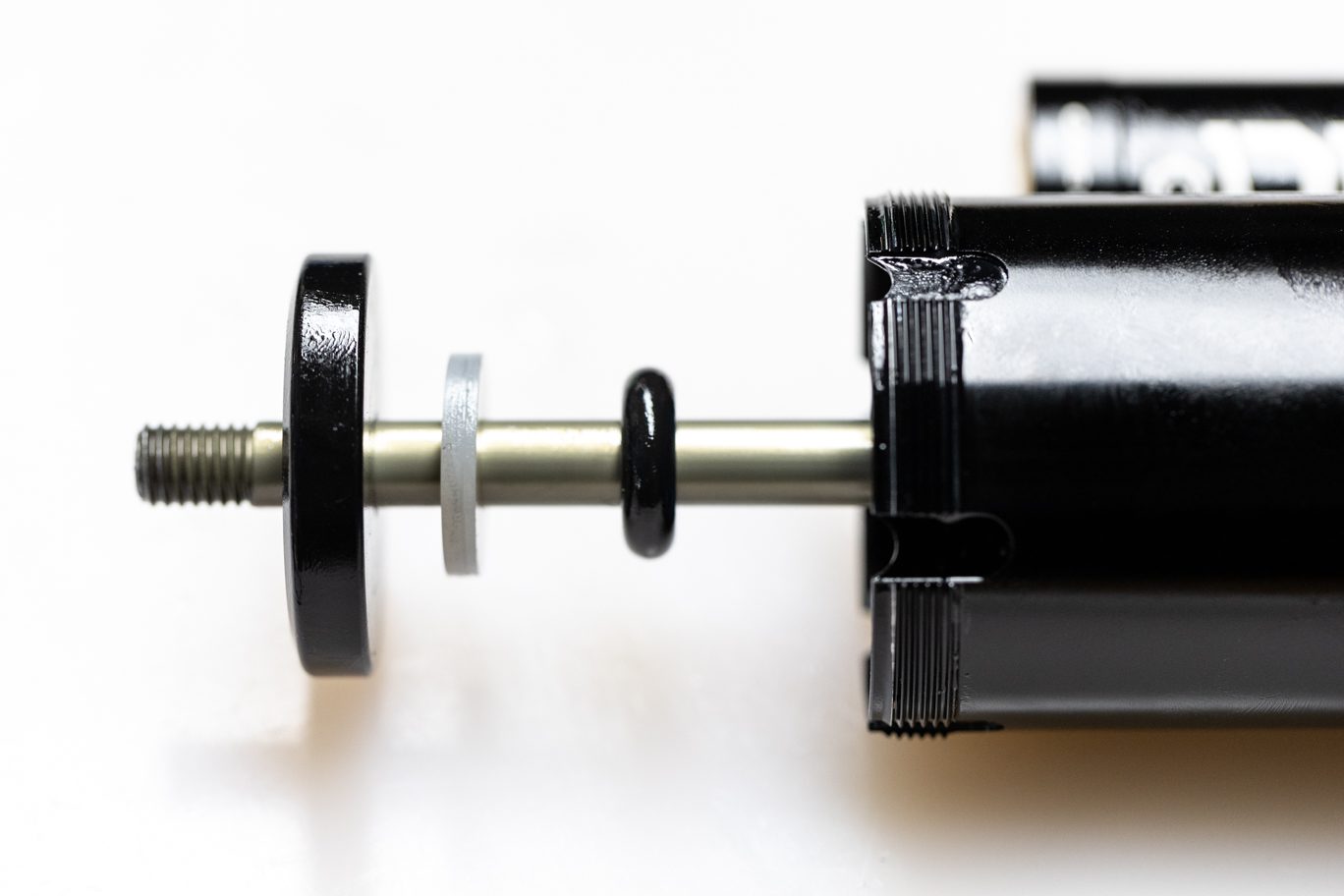

Using 1/2″ crowsfoot, unthread end eye from shaft. Remove stroke reduction and/or spacer (if present) and bottom out bumper. Remove inner air can. Pinch & remove and discard outer air can o-rings from inner air can and end eye.

TSB005 – DBair/DBair CS Stop Shim

Clamped for End Eye Removal

Freeing End Eye

End Eye Removed, Stroke Reduction, Spacer & Bottom Out Bumper Shown

Stroke Reduction Removed

Spacer and Bottom Out Bumper Removed

Inner Air Can Removal

Outer Air Can O-Rings Removal

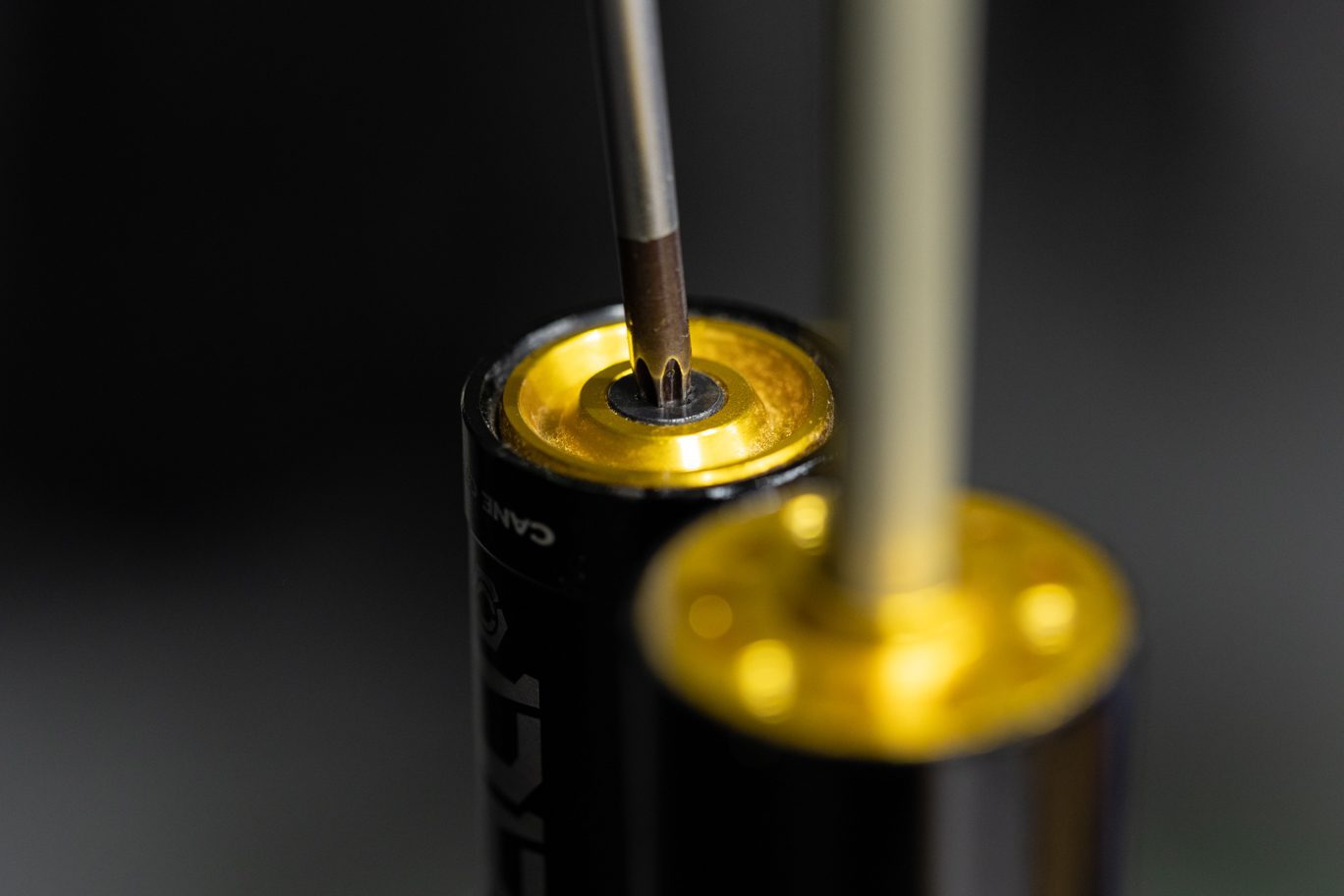

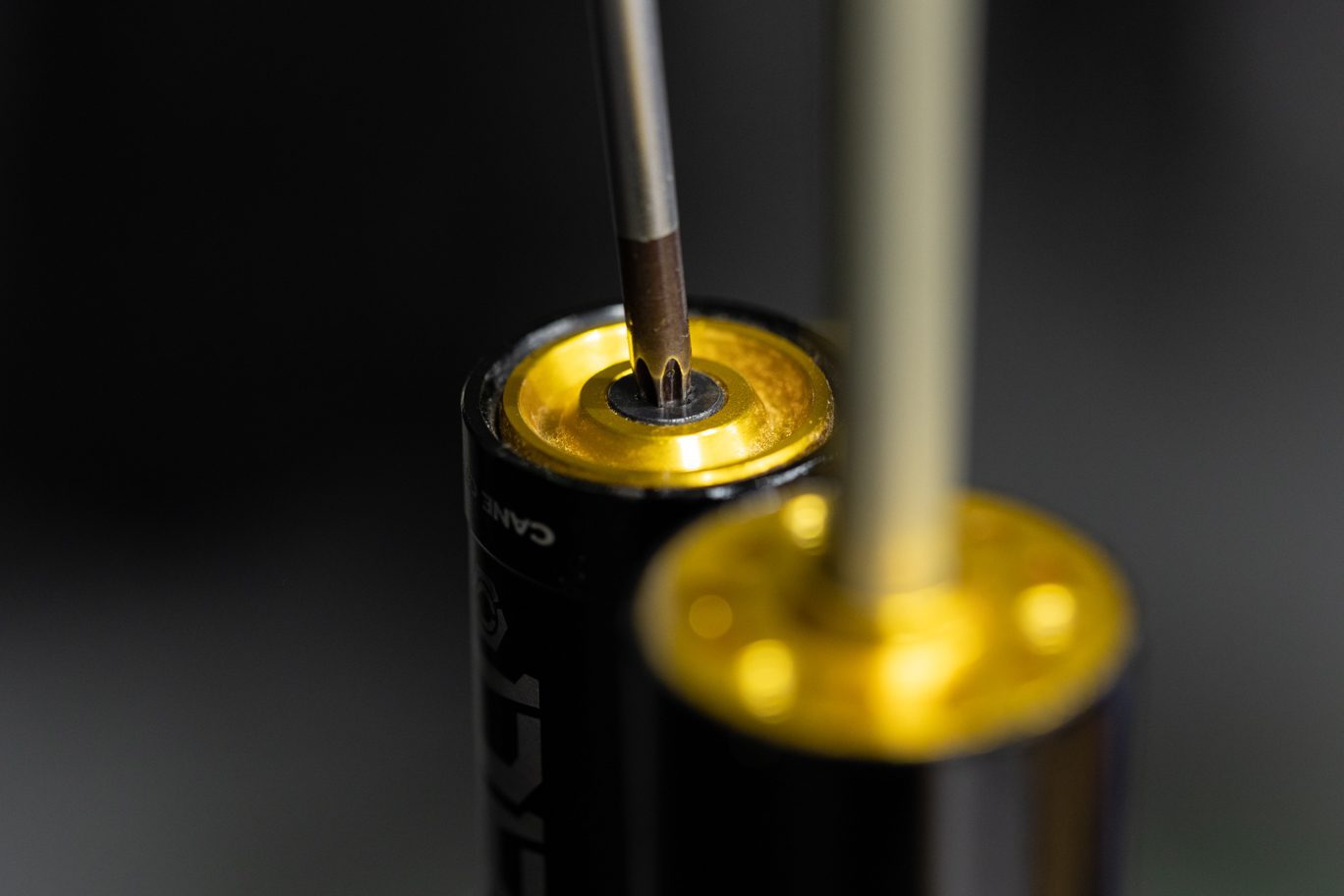

Step 4 - Air Piston Removal

Clamp shock at valve body. Using T20, remove 3 air piston screws. Remove air piston. Remove and discard air piston o-ring, back up L-rings and quad ring.

TSB022 – DBair CS Air Piston Change

If gold piston is present, replace with a new, blue piston (AAD1796).

Air Piston Set Screw Removal

Air Piston Removal

Air Piston O-Ring Removal

First Air Piston Back Up L-Ring Removal

Air Piston Quad Ring Removal

Second Air Piston Back Up L-Ring Removal

Step 5 – Air Seal Head Removal

Remove air seal head from outer damper tube. Remove and discard wiper, air seal head o-ring, back up ring, quad ring and glide ring. Remove and discard sag o-ring from out damper tube.

TSB014 – DBair/DBair CS Air Seal Head Quad Ring Change

Air Seal Head Removal

Air Seal Head Wiper Removal

Air Seal Head O-Ring Removal

Air Seal Head Back Up Ring Removal

Air Seal Head Glide Ring Removal

Air Seal Head Stripped

Sag O-Ring Removal

Damper Disassembly

Step 1 – Nitrogen Bleed & Oil Removal

***Use caution as nitrogen is pressurized.***

Using T20, remove gas fill screw and bleed any gas with fill needle. Using T20, remove oil fill screw. Cycle shaft to remove all damper fluid. Temporarily reinstall end eye if necessary to help cycle shaft.

Gas Fill Screw Removal

Gas Fill Needle Inserted

Bleeding Gas

Oil Fill Screw Removal (Standard)

Oil Fill Screw Removal (Trunnion)

Oil Fill Screw Removed

Cycling Oil From Damper

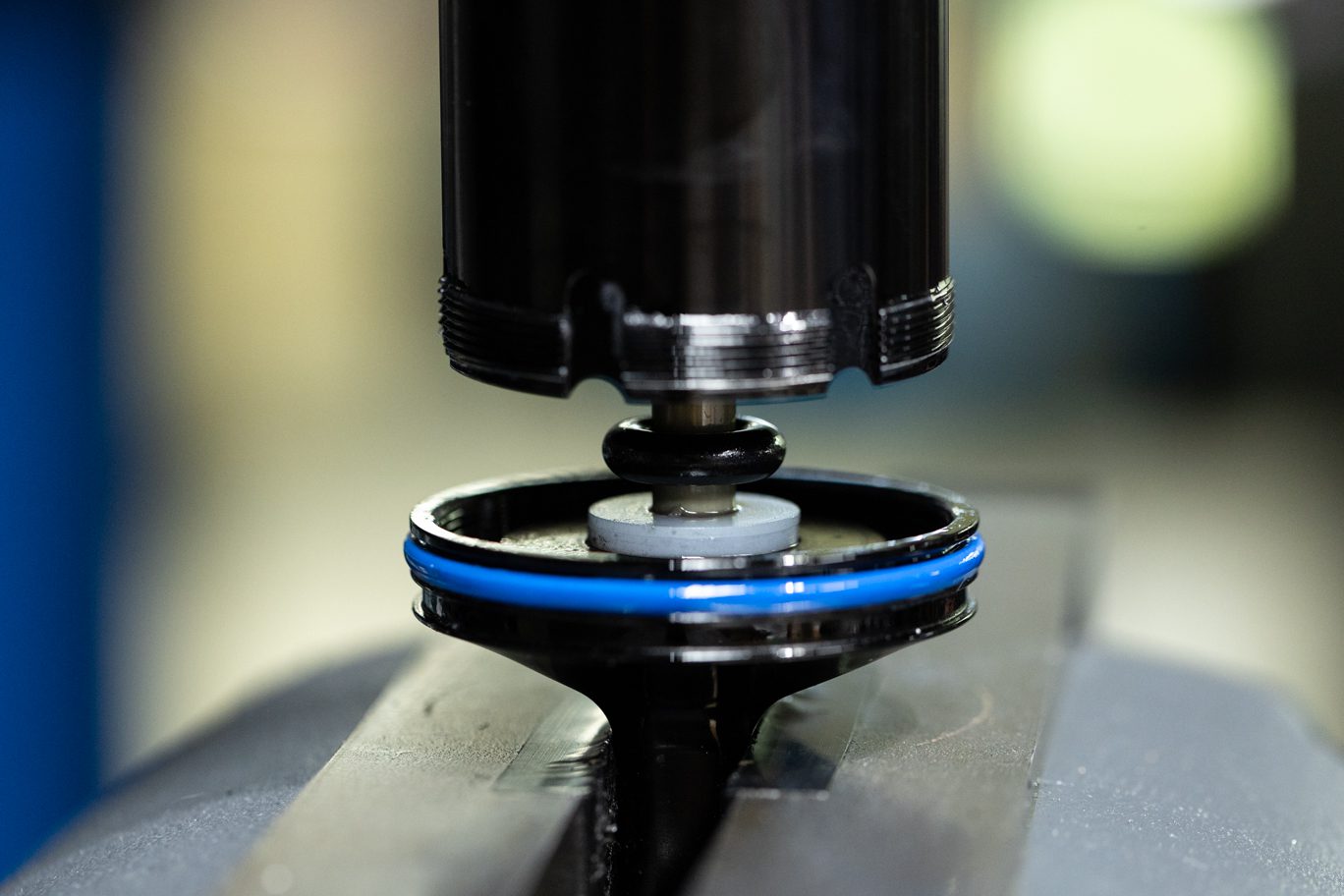

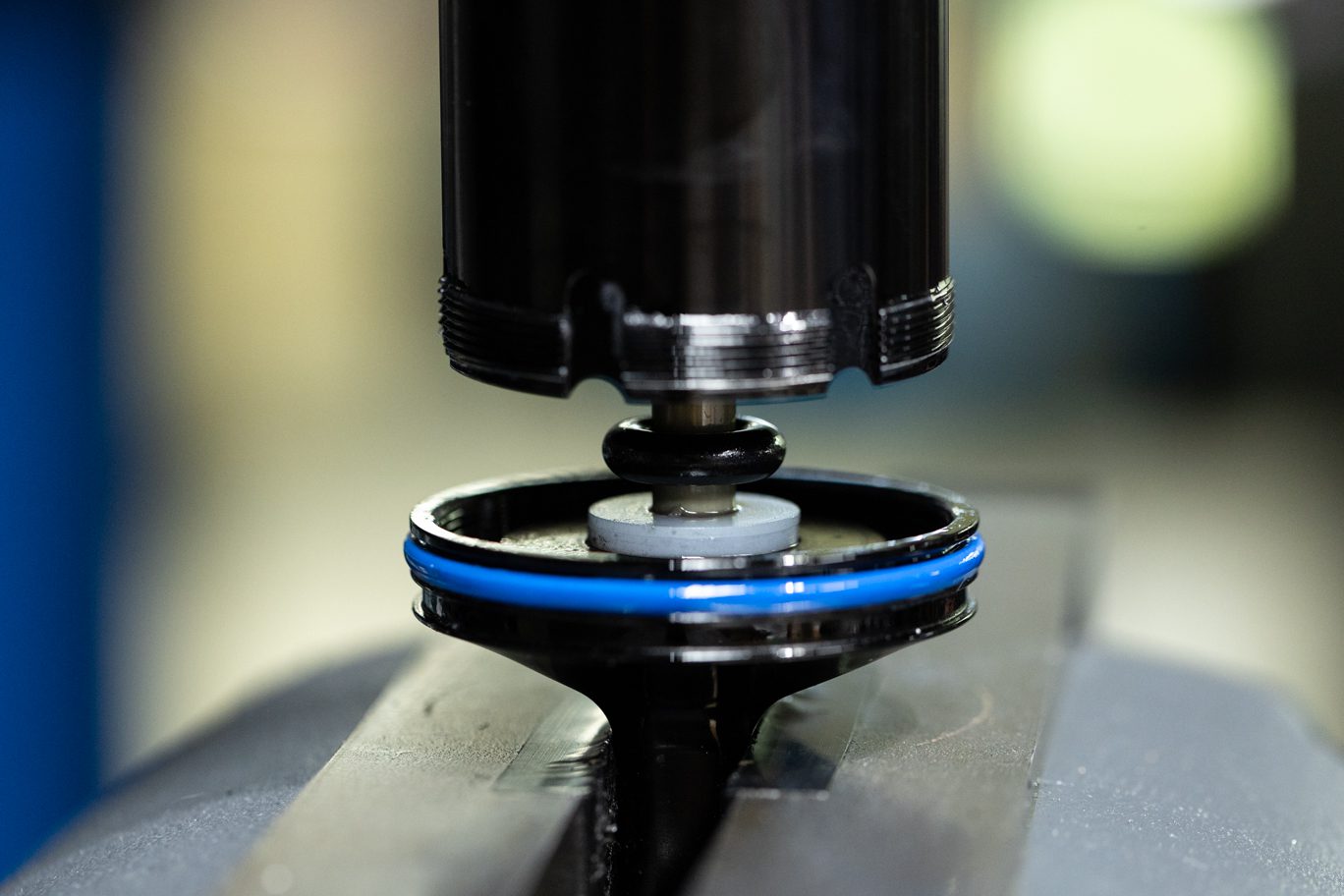

Step 2 – Reservoir End Removal

Depress reservoir end cap to expose circlip. IFP setting tool may be used. Remove reservoir tube circlip. Remove end cap with IFP setting tool (DBT012). Pinch & remove and discard res end o-ring.

Threading IFP Tool into Res End

Depressing Res End

Res End Circlip Removal

Res End Removal

Res End O-Ring Removal 1

Res End O-Ring Removal 2

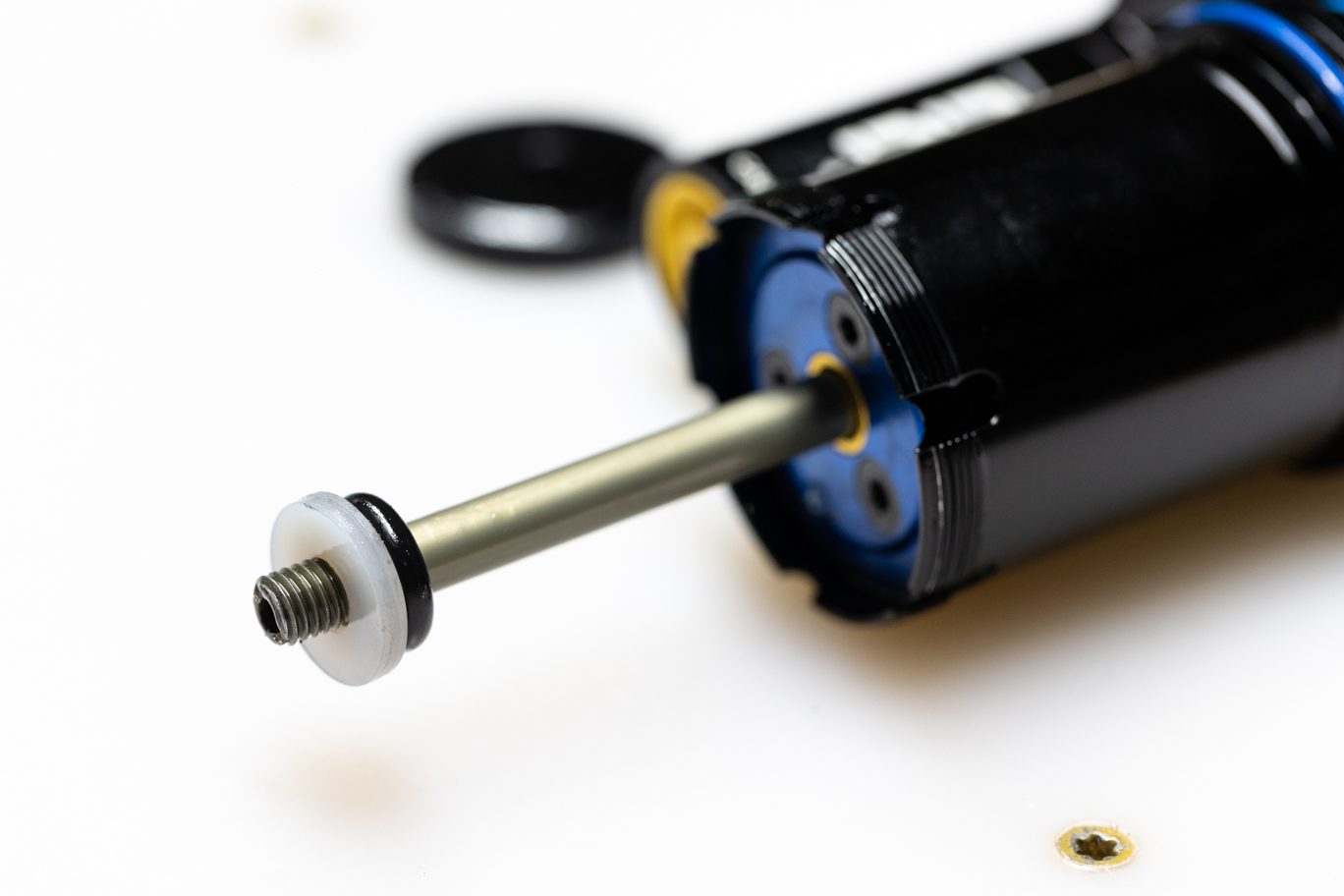

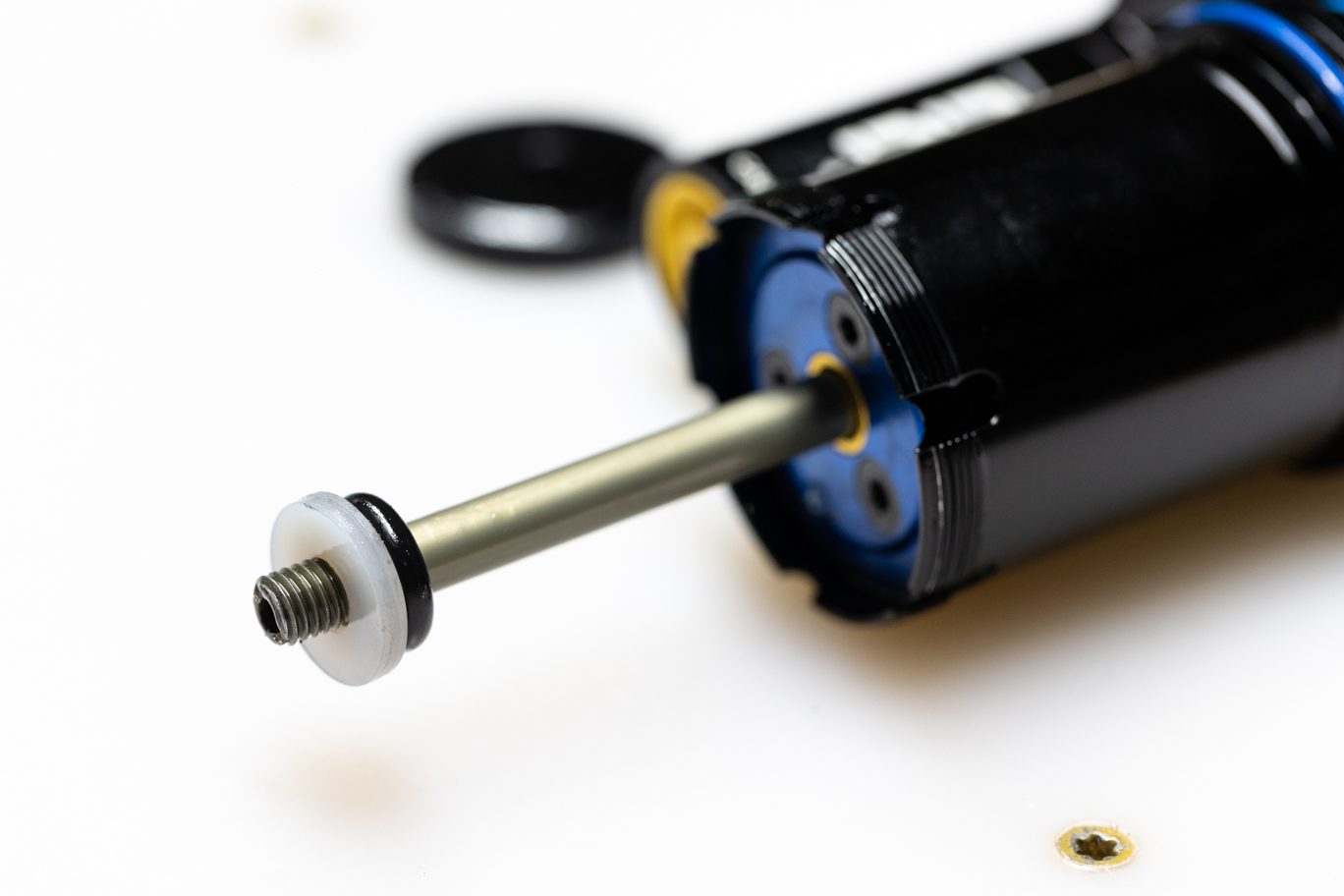

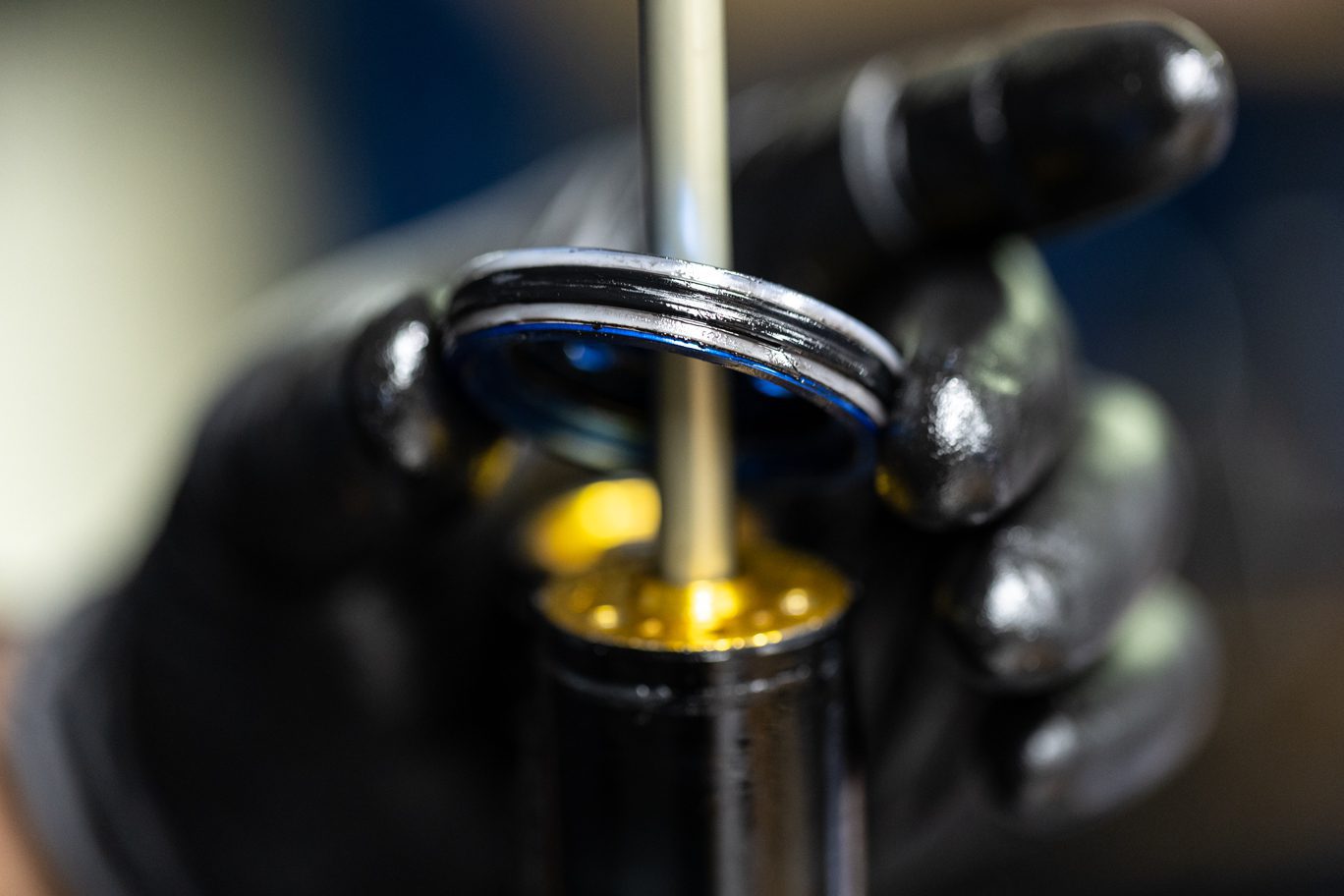

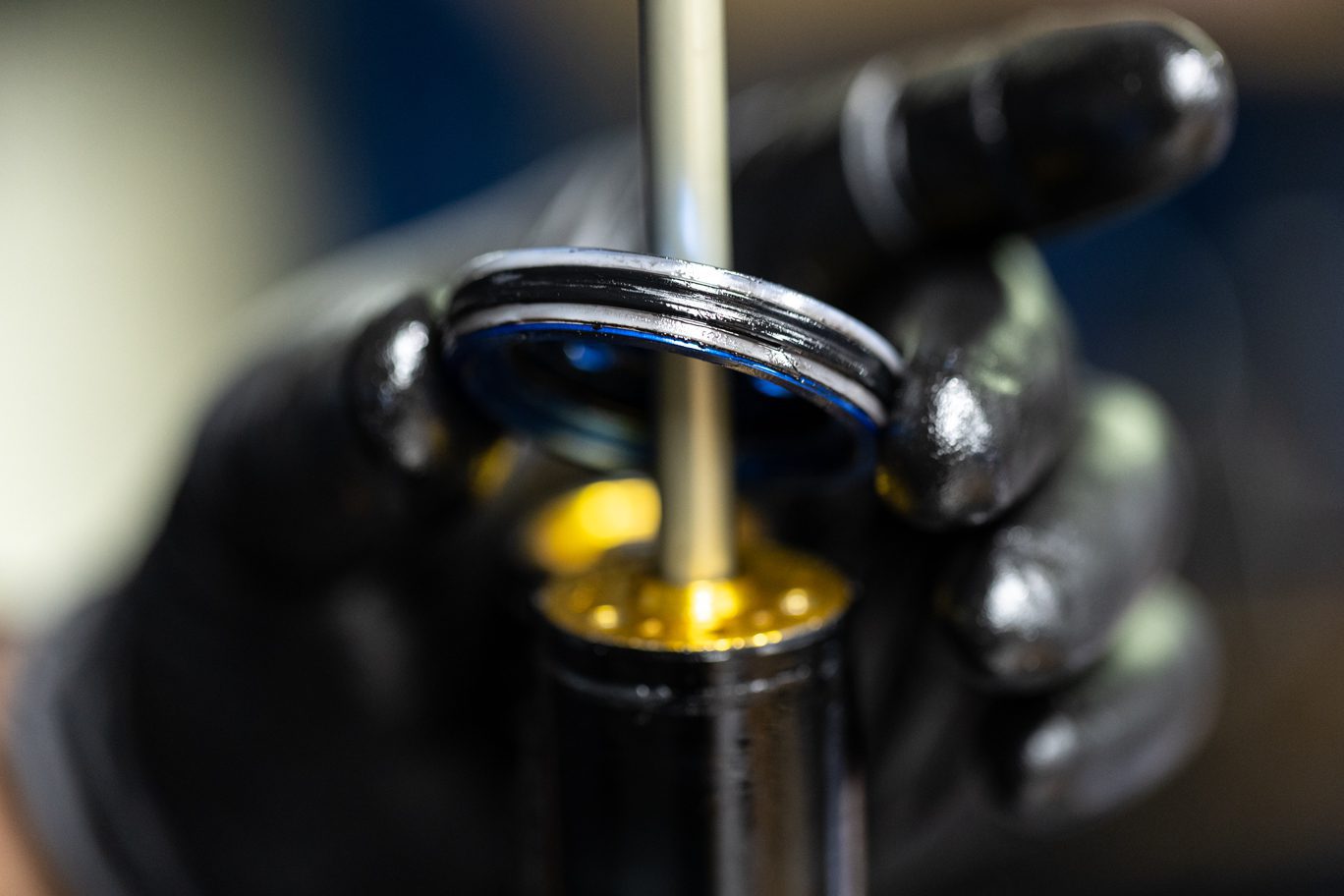

Step 3 – Oil Seal Head/Shaft Assembly Removal

Using Oil Seal Head tool, unthread oil seal head from outer damper tube. Take care not to use threaded holes on seal head. Remove complete shaft assembly. Using spanner, remove inner damper tube by pulling straight up.

Oil Seal Head, Noting Threaded Holes

Oil Seal Head Removal

Oil Seal Head Unthreaded

Shaft Assembly Removed

Hooking Inner Damper Tube

Inner Damper Tube Removal

Step 4 – IFP Removal

Using IFP tool, remove the IFP. Pinch & remove and discard IFP quad ring. Remove any remaining oil and thoroughly clean outer damper tube, reservoir tube and cylinder head.

IFP Removal

IFP Removed

IFP Quad Ring Removed

Oil Disposal

Shock Body Cleaning

Step 5 – Outer Damper & Res Tube Inspection (Removal if necessary)

Thoroughly inspect damper tube and res tube. Replace if necessary. Test tightness of outer damper tube and reservoir tube. If either comes loose without much force, remove completely. Otherwise, only remove if replacing.

With outer damper tube and/or res tube removed, remove and discard o-rings. Thoroughly clean all Loctite residue from cylinder head threads.

Testing (and Removing if Necessary) Outer Damper Tube

Threads Before Cleaning

Cylinder Head O-Ring Removal 1

Cylinder Head O-Ring Removal 2

Testing (and Removing if Necessary) Res Tube

Cleaning Threads

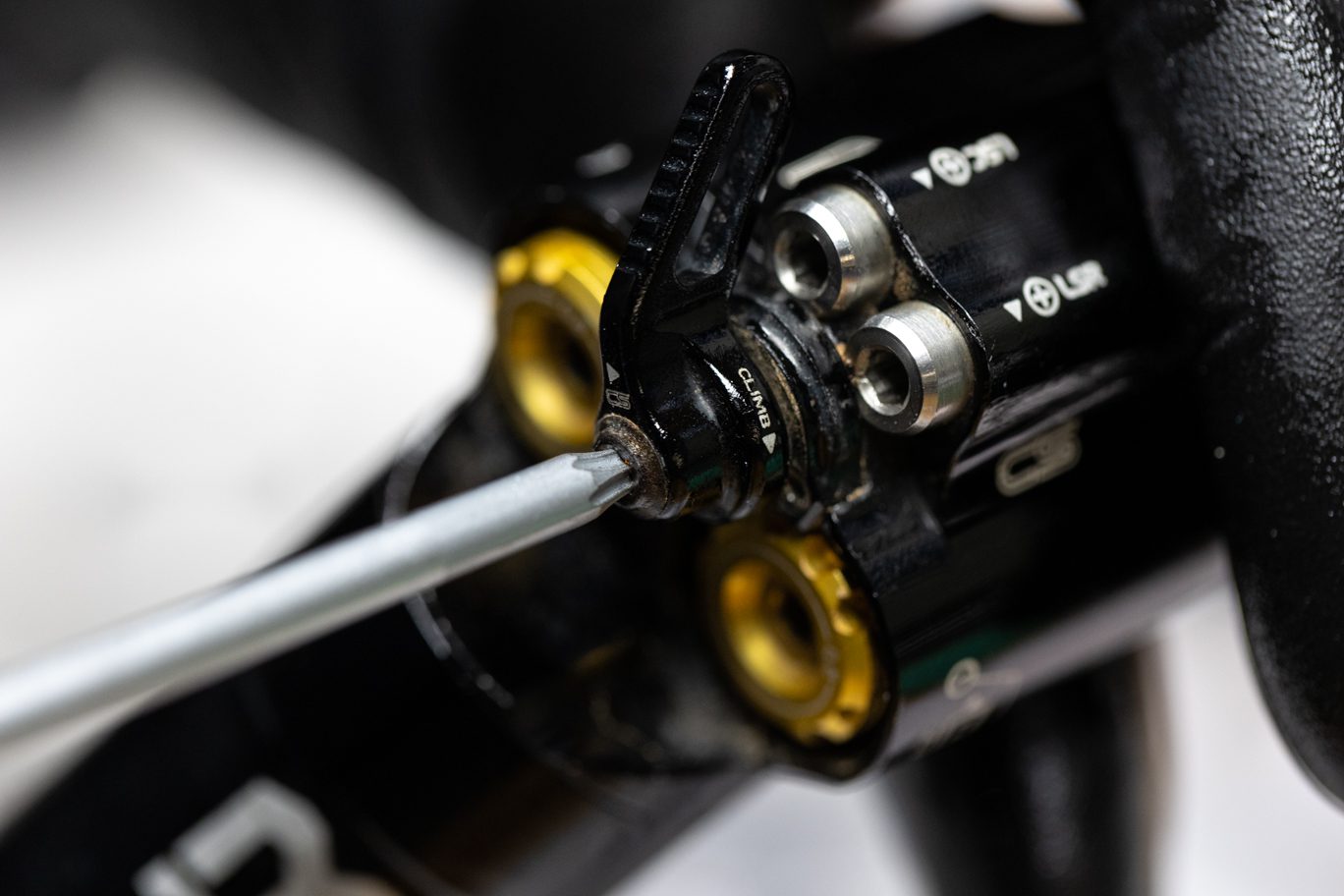

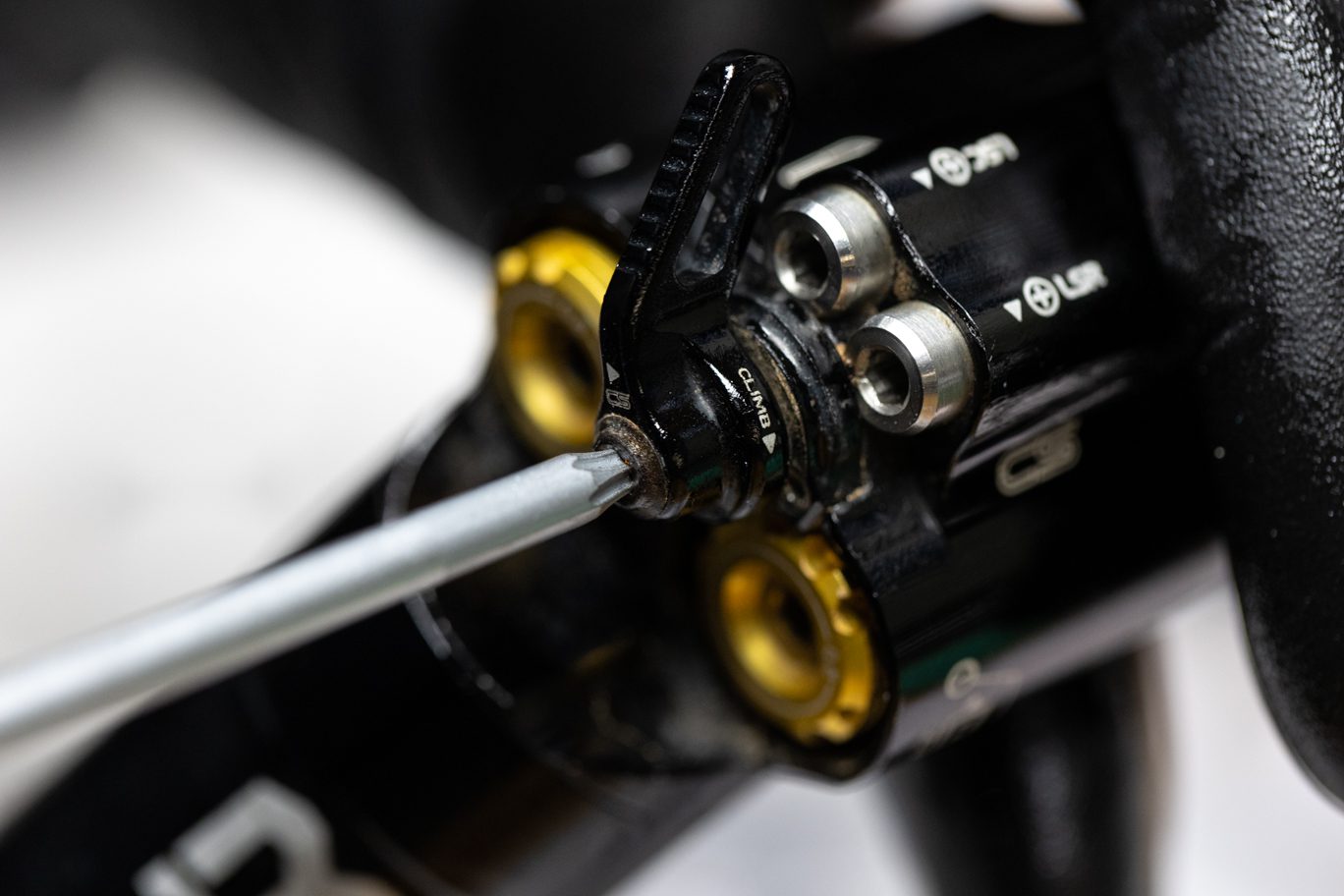

Step 6 – Climb Switch & CS Cover Removal

Using T10, remove Climb Switch screw and Climb Switch. Using 1.5mm Allen, remove Climb Switch cover plate screws and cover plate.

Climb Switch Screw Removal

Climb Switch Removal

Climb Switch Cover Plate Screw Removal 1

Climb Switch Cover Plate Screw Removal 2

Climb Switch Cover Plate Removal

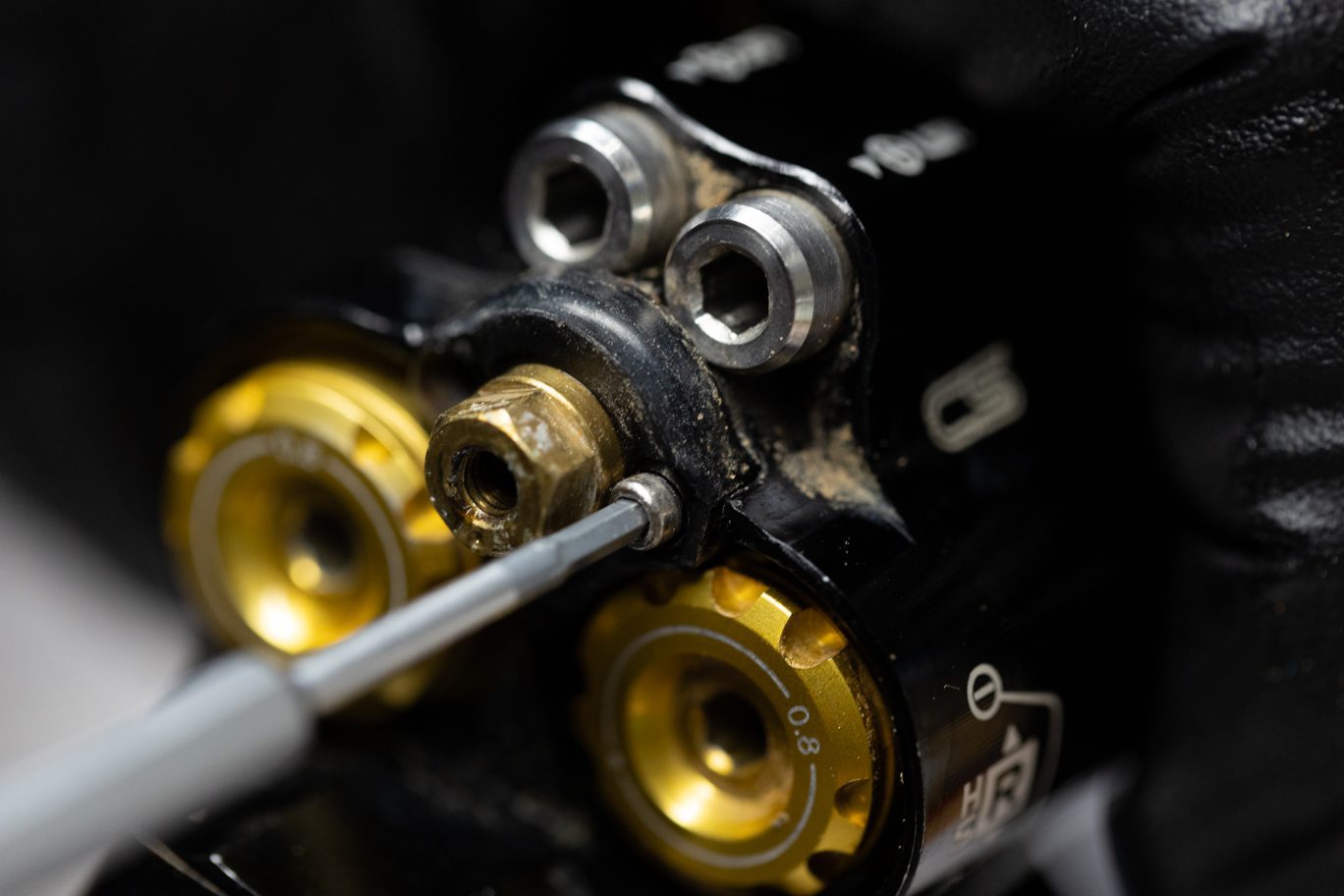

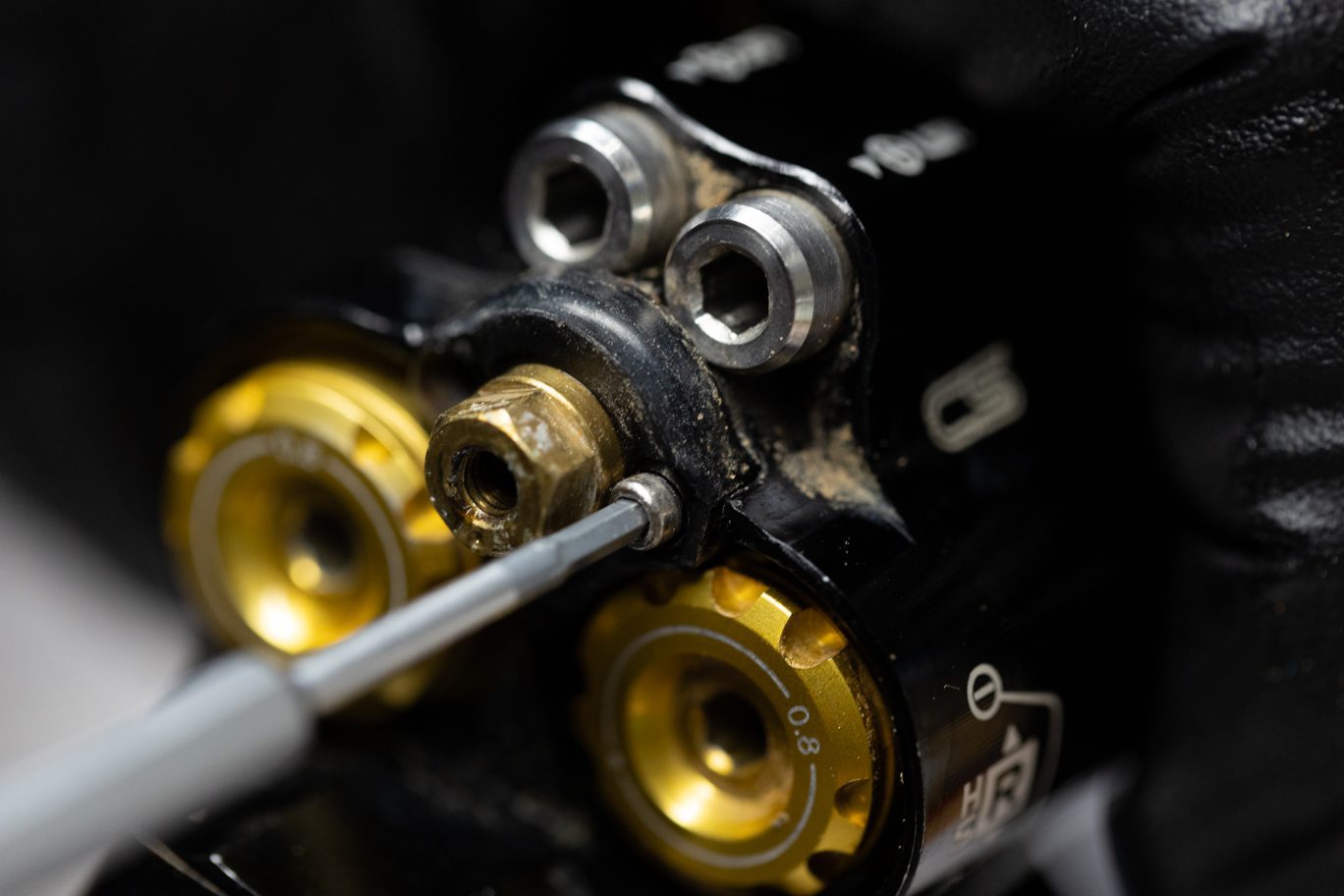

Step 7 – High Speed Adjusters Removal

Using 3mm Allen, remove High Speed adjusters. Take note of the Rebound adjuster (0.8 with port) and spring (red, 30wt weight) and Compression adjuster (will vary from 0.0 without port, to 0.8, 1.0 or 1.2 with port) and spring (yellow, 10wt or standard 20wt). Spring color may have worn off. Pinch & remove and discard High Speed adjuster o-rings.

HSR Adjuster Removal

HSR Adjuster Removed

HSC Adjuster Removed

High Speed Adjusters Removed, Rebound on Right

High Speed Adjuster w/ Port (0.8), Front

High Speed Adjuster w/ Port (0.8), Rear

High Speed Adjuster w/o Port (0.0), Front

High Speed Adjuster w/o Port (0.0), Rear

High Speed Adjuster External O-Ring Removal

High Speed Adjuster Poppet O-Ring Removal

Step 8 – High Speed Valve Seat Check

Using CS Valve Seat tool (AAD0756), check for proper torque (4.8 Nm) on valve seats. No need to remove valve seats as part of a standard service.

Valve Seat Tool

Valve Seat Torque Check

Step 9 – Climb Switch Spool Valve Removal

Using 6mm socket, thread spool valve closed (clockwise) and note location of the indicator dot. Then open (counterclockwise) the valve at least half a turn and then onto indicator dot at the 6:00 position. This is the default setting for reassembly. Make note of this position from fully closed. Unthread and remove spool valve assembly. Pliers may be necessary to remove assembly once completely unthreaded. Remove and discard spool valve o-ring. Remove and clean detent balls and spring.

Spool Valve Properly Clocked Ahead of Removal

CS Spool Valve Removal

CS Spool Valve Removal Past O-Ring w/ Pliers

CS Spool Valve Removed

CS Spool Valve O-Ring Removed

CS Spool Valve Detent Balls & Spring Removed

Step 10 – Low Speed Needle Removal

Using 3mm Allen, remove Low Speed needles. Pliers may be necessary to remove assembly once completely unthreaded. Take note of labeling on needles for reinstallation back into same circuit. Remove and clean detent balls and spring. Pinch & remove Low Speed needle o-rings.

Low Speed Rebound Needle Removal 1

Low Speed Rebound Needle Removal 2

Low Speed Compression Needle Removal 1

Low Speed Compression Needle Removal Noting Labeling

Low Speed Compression Needle Removal 2

Low Speed Rebound Needle Detent Balls & Spring Removal

Low Speed Rebound Needle O-Ring Removal

Continue to Part 2

Next